Abstract

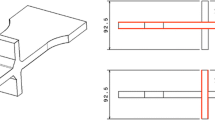

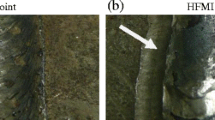

Investigations have been carried out regarding the fatigue strength of welded details improved by high frequency treatment methods. These methods increase the fatigue strength by cold forming of the surface, so that the weld toe is smoothened, the surface hardness is increased and compressive residual stresses are present up to a depth of 1 to 1.5 mm. In this paper, the surface residual stresses at the weld toe are investigated before and after different loading conditions and for different steel grades. It is shown that only high tensile fatigue loading can lead to a slight residual stress relaxation for low-strength steels. The fatigue crack behaviour is analysed in more detail. The crack propagation rates with and without surface treatment are investigated, using defined lines of rest. The study shows that crack propagation in the edge layers is reduced. Several cracks may start in the UIT-treated zone but will not propagate further, until one final crack, often close to the edge of the specimens, will lead to failure. The results of fatigue tests for butt welds and longitudinal stiffeners improved by high frequency hammer peening are presented. The fatigue strength is seen to be doubled. For high-strength steels, the improvement at different load levels is identical, but for lower-strength steels, high stress ranges lead to reduced improvement. This fact results in flatter SN-curves and can be explained by the lower maximum of residual stresses and residual stress relaxation.

Similar content being viewed by others

References

Dürr A.: Zur Ermüdungsfestigkeit von Schweißkonstruktionen aus höherfesten Baustählen bei Anwendung von UIT-Nachbehandlung, Fatigue strength of welds out of high strength steel applying UIT-treatment, Dissertation, Universität Stuttgart, Institut für Konstruktion und Entwurf, Stuttgart, 2007 (in German).

Kuhlmann U., Dürr A., Bergmann J., Thumser R.: Effizienter Stahlbau aus höherfesten Stählen unter Ermüdungsbeanspruchung, Efficient steel design out of high strength steel under fatigue loading, Forschungsvereinigung Stahlanwendung (Edit.), Verl.- und Vertriebsges, Düsseldorf, 2006 (in German).

Lihavainen V.-M.: A novel approach for assessing the fatigue strength of ultrasonic impact treated welded structures, Dissertation, Lappeenranta University of Technology Department of Mechanical Engineering, Lappeenranta, 2006.

Roy S.: Experimental and analytical evaluation of enhancement in fatigue resistance of welded details subjected to post-weld ultrasonic impact treatment, Dissertation, Lehigh University Department of Civil and Environmental Engineering, Bethlehem, Pa., 2006.

Statnikov E.S., Muktepavel V.O., Blomqvist A.: Comparison of Ultrasonic Impact treatment (UIT) and other fatigue life improvement methods, Doc. IIW-1506-00 (ex-doc. XIII-1817–00), Welding in the World, 2002, vol. 46, no. 3/4, pp. 20–32.

Kudryavtsev Y.: Effect of plastic strains and residual stresses, caused by ultrasound shock treatment, on the fatigue strength of welded joints, The Paton Welding Journal, vol. 7, no. 12, 1995, pp. 667–671.

Ummenhofer T., Weich I., Nitschke-Pagel Th.: Extension of life time of welded dynamic loaded structures, IIW Doc. XIII-2085–05, 2005.

Ummenhofer U., Weich I., Nitschke-Pagel Th.: Extension of life time of fatigue loaded structures, The Proceedings of the 16th International Offshore and Polar Engineering Conference, San Francisco, California, USA, May 28–June 2, 2006, no. IV, pp. 98–105.

Cheng X., Fisher J.W., Prask H.J., Gnäupel-Herold T., Yen B.T., Roy S.: Residual stress modification by post-weld treatment and its beneficial effect on fatigue strength of welded structures, International Journal of Fatigue, 2003, vol. 25, no. 9–11, pp. 1259–1269.

Nitschke-Pagel Th., Dilger K., Eslami H., Weich I., Ummenhofer T.: Residual stresses and near surface material condition of welded high strength steels after high frequency mechanical post-weld treatments, IIW Doc. XIII-2153–07, 2007.

Weich I., Ummenhofer T., Nitschke-Pagel Th., Dilger K., Eslami H.: Influence of treatment and loading conditions on the fatigue strength of welds improved by high frequency peening, IIW Doc. XIII-2218–08, 2008.

Weich I.: Ermüdungsverhalten mechanisch nachbehandelter Schweißverbindungen in Abhängigkeit des Randschichtzustands, Fatigue behaviour of mechanical post weld treated welds depending on the edge layer condition, Dissertation, Technische Universität Braunschweig, Braunschweig, 2009 (in German).

Vöhringer O.: Abbau von Eigenspannungen, Residual stress relaxation, Macherauch E., Hauk V. (Edit.): Eigenspannungen — Entstehung — Messung — Bewertung, DGM Informationsgesellschaft mbH Verlag, Oberursel, 1983, pp. 49–83 (in German).

Vöhringer O.: Stabilität von Eigenspannungen: Eigenspannungsabbau unter quasistatischer und schwingender mechanischer Beanspruchung sowie bei erhöhten Temperaturen, Stability of residual stresses under quasi-static and cyclic mechanical loading as well as under increased temperature, DGM-Fortbildungspraktikum: Ermittlung und Bewertung von Eigenspannungen, DGM Informationsgesellschaft mbH Verlag, Oberursel, 1998 (in German).

Scholtes B.: Eigenspannungen in mechanisch randschichtverformten Werkstoffzuständen — Ursachen, Ermittlung und Bewertung, Residual stresses in mechanical edge layer deformed material conditions — Reasons, measurement and evaluation, DGM Informationsgesellschaft mbH Verlag, Oberursel, 1991 (in German).

Hanagarth H.: Auswirkungen von Oberflächenbehandlungen auf das Ermüdungsverhalten von TiAl6V4 und 42CrMo4 bei erhöhter Temperatur, Influence of surface treatment on the fatigue behaviour of TiAL6V4 and 42CrMo4 under increased temperature, Dissertation, Universität Karlsruhe, Karlsruhe, 1989 (in German).

Holzapfel H.: Das Abbauverhalten kugelstrahlbedingter Eigenspannungen bei 42 Cr Mo 4 in verschiedenen Wärmebehandlungszuständen, Relaxation behaviour of residual stresses caused by shot peening for 42CrMo4 in various heat treatment states, Universität Karlsruhe, Karlsruhe, 1994 (in German).

Wick A.: Randschichtzustand und Schwingfestigkeit von 42 CrMo 4 nach Kugelstrahlen unter Vorspannung und bei erhöhter Temperatur, Edge layer condition and fatigue strength of 42 CrMo 4 after shot peening under pretension and increased temperature, Dissertation, Universität Karlsruhe, Karlsruhe, 1999 (in German).

Menig R.: Randschichtzustand, Eigenspannungsstabiltät und Schwingfestigkeit von unterschiedlich wärmebehandelten 42 CrMo 4 nach modifizierten Kugelstrahlbehandlung, Edge layer condition, residual stress stability and fatigue strength of heat treated 42CrMo4 after modified shot peening processes, Dissertation, Universität Karlsruhe, Institut für Werkstoffkunde, Karlsruhe, 2002 (in German).

Heeschen J., Nitschke-Pagel Th., Wohlfahrt H.: Der Einfluss der Nahtgeometrie auf die Dauerschwingfestigkeit von Schweißverbindungen aus einem hochfesten Feinkornbaustahl StE 690, Influence of weld geometry on the fatigue strength of welds out of high strength steel StE 690, Abschlussbericht zum DFG-Forschungsvorhaben Wo 344/1 im Forschungsschwerpunkt „Fertigung und Bauteilverhalten“, Universität- Gesamthochschule Kassel, Institut für Werkstofftechnik, Kassel, 1990 (in German).

Ummenhofer T.; Weich I.: Hochfrequente Hämmerverfahren — Steigerung der Ermüdungsfestigkeit neuer und bestehender geschweißter Stahlkonstruktionen, High frequency hammer peening — Increase of the fatigue strength of new and existing welded steel structures, Bauingenieur, 2007, Vol. 82, No. 5, pp. 237–244 (in German).

Ummenhofer T., Weich I., Bergers J., Herion S.: Reduktion der Wanddicken bei Tragtürmen von Windenergieanlagen durch den Einsatz höherfester Stähle, Reduction of plate thickness of wind energy converters by the use of high strength steel, Stahlbau, 2007, Vol. 76, No. 9, pp. 643–649 (in German).

Eurocode 3: Design of steel structures — Part 1–9: Fatigue, EN 1993-1–9:2005.

Hobbacher A.: Recommendations for fatigue design of welded joints and components, Doc. IIW-1823-07 (ex-doc. XIII-2151r4-07/XV-1254r4–07), The Welding Research Council, Inc., New York, WRC Bulletin 520, 2009.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Weich, I., Ummenhofer, T., Nitschke-Pagel, T. et al. Fatigue Behaviour of Welded High-Strength Steels after High Frequency Mechanical Post-Weld Treatments. Weld World 53, R322–R332 (2009). https://doi.org/10.1007/BF03263475

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03263475