Abstract

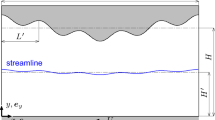

For practical calculations, the Reynolds equation is frequently used to analyze the lubricating flow. The full Navier-Stokes Equations are used to find validity limits of Reynolds equation in a lubricating flow regime by result comparison. As the amplitude of wavy upper wall increased at a given average channel height, the difference between Navier-Stokes and lubrication theory decreased slightly ; however, as the minimum distance in channel throat increased, the differences in the maximum pressure between Navier-Stokes and lubrication theory became large.

Similar content being viewed by others

Abbreviations

- h:

-

Height of channel

- h0, h1 :

-

Average channel distance, amplitude of the cosine wavy wall, repectively

- p:

-

Pressure

- P0, p2 :

-

Perturbation pressure of order 0, 2

- Re:

-

Reynolds number ρvlref/β

- Q:

-

Volume flow rate

- u, v, w:

-

Velocity component

- x, y, z:

-

Rectangular Cartesian coordinates

- ε:

-

Perturbation parameter, h/L

- Ψ:

-

Stream function

- Ψ0, Ψ2, Ψ4 :

-

perturbation stream function of order 0, 2, 4

- μ:

-

Viscosity

- ν:

-

Kinematic viscosity

- () ’:

-

Derivative

- min:

-

minimum

- max:

-

maximum

- L:

-

Lower surface

- U:

-

Upper surface

- ( )x :

-

Derivative with respect to x

References

Carvalho, M. S. and Scriven, L. E., 1997. “Flows in Forward Deformable Roll Coating Gaps: Comparison between Spring and Plain-Strain Models of Roll Cover,”Journal of Computational Physics, Vol. 138, No. 2, pp. 449–479.

Choi. B. L., Lee, A. S., and Choi, D. H., 2001, “A Lubrication Performance Analysis of Mechanical Face Seals Using Galerkin Finite Element Method,”KSME J. part A, vol. 25, pp. 916–922.

Dowson, D. and Wang, D., 1994, “Analysis of the Normal Bouncing of a Solid Elastic Ball on an Oily Plate,”Wear, Vol. 179, pp. 29–37.

Dusey, M., 1993,Numerical Analysis of Lubrication Theory and Peristaltic Transport in The Esophagus, Ph. D. Thesis, Pennsylvania State University, University park, PA.

Fluid Dynamics Analysis Package Ver. 7.0, 1993, Fluid Dynamics International, Inc.,

Hsu, C. H. and Lee, R., 1994, “Advanced Multilevel Solution of Elastohydrodynamic Lubrication Circular Contact Problem,”Wear, Vol. 177, pp. 117–127.

Hua, D. Y. and Kohnsari, M. M., 1995, “Application of Transient Elastohydrodynamic Lubrication Analysis for Gear Transmissions,”Tribology Trans. Vol. 38, pp. 905–913.

Schmuck, M. R., Chung, J. B., Schultz, W. W. and KannateyAsibu, E. Jr., 1991, “Analysis of Fluid Flow Under a Grinding Wheel. ”Trans. ASME, Vol. 113, pp. 190–197.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, D.J., Seo, D.K. & Schultz, W.W. A comparison study between navier-stokes equation and reynolds equation in lubricating flow regime. KSME International Journal 17, 599–605 (2003). https://doi.org/10.1007/BF02984461

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02984461