Abstract

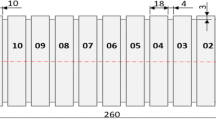

The surface integrity of inconel-718 nickel-base superalloy was investigated using orthogonal cutting at various cutting speeds, depths of cut and chip-tool contact lengths under unlubricated conditions. The experimental work involved the determination of residual stress, plastic strain and microhardness distribution in the surface region and the examination of the surface and subsurface using scanning electron and optical microscope. The results are interpreted in terms of the variation in shear-plane length and consequently the variation in tool forces with the cutting conditions. The results are compared with similar results obtained under lubricated conditions. It is found that the lubricant is effective at low cutting speeds in reducing the tool forces that led to lower hardness and plastic strain in the surface region. In general, the severity of surface damage in terms of intensity and total area affected was decreased with the application of a lubricant. Both residual stresses and plastic strains decreased and the quality of the machined surface improved with an increase in cutting speed, a decrease in depth of cut and with tools having controlled chip-tool contact lengths.

Similar content being viewed by others

References

Sadat, A.B. and Reddy, M.Y.K., “Surface Integrity of Inconel-718 Nickel Base Superalloy Using Controlled Contact Length Tools, Part I: Lubricated,” Experimental Mechanics,32 (3), (Sept. 1992).

Ernst, H. andMerchant, M.E., “Chip Formation, Friction and High Quality Machined Surfaces, in Surface Treatment of Metals,”American Society of Metals,29,299 (1941).

Sadat, A.B., “Surface Characteristics of Machined Inconel-718 Nickel Base Superalloy Using Natural and Controlled Contact Length Tools,” Intl. J. Mach. Tool Des. and Rech.,27 (3), (1987).

Sadat, A.B. andBailey, J.A., “Some Observation of the Surface Damage of Machined Bearing Bronze,”Wear,108 (3),255 (1986).

Bailey, J.A. andElkhaberry, M.M., “Surface Integrity in Machining Solution-Treated and Aged 2024-Aluminum Alloy, Using Natural and Controlled Contact Length Tools. Part II — Lubricated Condition,”J. Eng. Mat. and Tech.,106,161–164 (1984).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sadat, A.B., Reddy, M.Y. Surface integrity of inconel-718 nickel-base superalloy using controlled and natural contact length tools. Part II: Unlubricated. Experimental Mechanics 33, 343–348 (1993). https://doi.org/10.1007/BF02322151

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02322151