Abstract

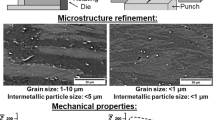

The present study proposes a novel process for refining a coarse and brittle intermetallic compound of Al9Si2Fe2 (β phase) in Al-12 mass%Si-2 mass%Fe alloy by an extrusion process using a ball-die, i.e., arranged ceramic balls instead of a conventional die. The alloy passes through the gap of the arranged balls, and subsequently by passing through a shape-giving die, the alloy is extruded as a rod. Size and arrangement of the balls are varied and the effect of them on the refinement of the β phase is investigated. Finer β phase was obtained with the larger contact area of the balls and the alloy. By the ball-die extrusion, the β phase was refined especially in the center of the extrudate due to the collision of the alloy extruded from the gaps of the balls. Also, the size of the eutectic Si and the grain size of the Al matrix were slightly refined by the ball-die extrusion. The ball-die extrudate exhibited higher elongation than the one of the conventional extrudate. The maximum elongation of 26% was obtained with the ball-die extrudate.

Similar content being viewed by others

1 Introduction

Al–Si alloys are widely used for automotive parts because of their light weight, excellent castability, high wear resistance and low thermal expansion coefficient [1, 2]. Recently, consumption of the alloys for the automotive parts have been increasing to reduce the vehicle weight, so as to achieve an increase in fuel efficiency and a reduction in CO2 emission. Moreover, more and more Al alloys have been produced from recycled Al scrap for the resource saving [3]. Therefore, it has been expected that the increase in the usage of the recycled Al alloys in the practical application can mitigate the global warming problems. However, most of the automotive components are produced from wrought alloys, which are produced only from virgin ingot of Al, not from recycled scrap. To produce secondary Al alloys from recycled scrap, it only takes approximately 5% of energy comparing to production of Al alloys from virgin ingot [4]. Thus, even if weight of vehicles is decreased by using Al alloys instead of steel, as far as the wrought alloys produced from virgin ingot are used, still a large amount of energy is required, and the global warming problems remain. Therefore, it is necessary to establish a recycling process for fabrication of wrought alloys.

Although such recycling process producing wrought alloys from wrought alloys has been required, can recycling is the only established process for wrought alloys [5]. One of the reasons why the recycling of wrought alloys has not been promoted is due to the strict limit of the impurity. The upper limit of the impurity is much smaller for the wrought alloys than for the cast alloys. During a recycling process, Al is often contaminated by Fe, which forms a coarse and brittle intermetallic compound such as Al9Si2Fe2 (β phase) in Al–Si alloys [6]. The β phase can be an initiation site of cracking and therefore, it significantly deteriorates mechanical properties of alloys [7]. It has been known that refinement of the β phase is effective to mitigate the deterioration [8]. For example, dramatic reduction in the size of the β phase has been achieved by addition of inoculant elements or the application of ultrasonic vibration to the molten alloy [9]. However, some problems have been remained, e.g., formation of other brittle phases or a narrow range of applicable temperature during solidification. Thus, in the present study, we propose a novel process to refine the coarse and brittle β phase in Al–Si–Fe alloys. We propose an extrusion process which is specialized for refining the β phase by using arranged ceramic balls instead of a conventional extrusion die. During the extrusion process, a metal billet passes through the gaps of the arranged balls, and the metal is extruded as a rod by subsequently passing through a conventional die. The gaps between the balls play a role of a bearing part of a conventional die, and the total contact area between the metal and the balls is much larger than that of a conventional die. Thus, we can expect a high strain on a metal by the ball-die extrusion. In the present study, the effect of the newly developed ball-die extrusion on the refinement of β phase is investigated by changing the size and arrangement of the balls. Moreover, the effect of the refinement on the mechanical properties is also investigated.

2 Experimental

An pure Al ingot with a purity of 99.99 mass%, Al-24.5 mass%Si alloy ingot, and pure Fe powder with a purity of 99.0 mass% were cast into a square bar with a cross section of 40 × 40 mm at 993 K to prepare an Al-12 mass%Si-2 mass%Fe alloy billet. The bar was cut into a cuboid of 40 mm in height for extrusion.

Figure 1 illustrates the schematic drawing of an extrusion equipment used in the present study. The Al–Si–Fe billet was placed in the container, and the ceramic balls, a holder, a spacer, a dummy Al–Si–Fe alloy block and a shape-giving die were placed from bottom up. A ram was placed on the shape-giving die and the ram was loaded and the Al–Si–Fe alloy billet was indirectly extruded into a bar having a square cross section of 9 × 9 mm. During the extrusion process, the billet firstly filled the gap between the balls, and then passed through the holder and spacer with pushing out the dummy alloy, and finally it was extruded from the shape-giving die. The extrusion temperature was 793 K and the ram speed was 0.5 mm/min. The extrusion ratio was 95%, which is calculated by dividing the area difference between the cross-sectional area of the billet and the shape-giving die hole by the cross-sectional area of the billet.

The extrusion was conducted with various arrangements of the balls. Figure 2 shows the arrangements of the balls in the present study; (a) with balls having 8 mm in a diameter (small-ball extrusion), (b) with balls having 10 mm in a diameter (large-ball extrusion), and (c) with double-layered balls having 8 mm in a diameter (double-layered extrusion). In the double-layered extrusion, a dummy material having the same chemical composition as an extrusion billet was put in between the layered balls to avoid stress concentration at the contact of the upper and lower balls. For a comparison, conventional extrusion was also conducted without the balls, the holder, the spacer, and the dummy material. Figure 3 illustrates the schematic drawings of the shape-giving die, the spacer and the holders shown in Fig. 1. The positions of the halls in the holders are different in the large-ball extrusion, and the small-ball and the double-layered extrusion.

To investigate the effect of the ball-die extrusion on the refinement of the β phase and the eutectic Si in the Al–Si–Fe alloy, the microstructures of all the extrudates and the as-cast billets were observed with an optical microscope, and the lengths of the β phase and the eutectic Si were measured. The microstructure of the Al matrix was also observed and analyzed with the Electron BackScatter Diffraction (EBSD).

To investigate the effect of the ball-die extrusion on the mechanical properties, tensile tests were conducted. The specimen was prepared with the wire discharge machine to coincide the tensile direction and the extrusion direction. The thickness and the gage length of the specimen were 1.4 and 5.2 mm, respectively. The tests were conducted at room temperature and at an initial strain rate of 1.0 × 10−3 s−1. The fractured surface was observed with Scanning Electron Microscopy (SEM) to investigate the fracture mechanism.

3 Results and discussion

3.1 Microstructure

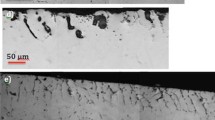

Figure 4a shows the microstructure of the as-cast Al-12 mass%Si-2 mass%Fe alloy. Figure 4b, c show the longitudinal section of the small-ball extrudate of the alloy near the surface and in the center of the extrudate, respectively. The black and white arrows in the figures indicate the eutectic Si and the β phase, respectively. In the as-cast alloy, the coarse β phase having a length of 100 to 500 μm, the eutectic Si and the dendritic structure of the Al matrix can be seen. The morphology of the observed eutectic Si is considered as faceted flake as is generally known in a previous study [10]. Near the surface of the extrudate (Fig. 4b), both the β phase and the eutectic Si were refined, and they were aligned longitudinally to the extrusion direction. In the center area (Fig. 4c), most of the β phase was finer than the ones near the surface, although the coarse β phase with a length of 50 to 100 μm was observed in some parts. It seems that higher strain was imposed on the center than the area near the surface in the small-ball extrudate. In a conventional extrusion process, higher strain is generally imposed to surface area of an extrudate [11], which conflicts with the result of the present extrusion. To check if this conflict occurred in other ball-die extrusion process, the lengths of the β phase was investigated with all kinds of extrudate in this study.

Figure 5 shows the average lengths of the β phase in the variety of extrudates with the standard deviation. In the as-cast sample, the average lengths of the β phase was approximately 215 μm. On the other hand, the lengths of the β phase in all the extrudates with balls are less than 50 μm. Thus, the β phase in all the extrudates were refined significantly by a severe deformation during the extrusion. Moreover, the lengths of the β phase in the small-ball extrudate and the large-ball extrudate are almost the same, while the lengths in the double-layered extrudate is slightly smaller than other ball-die extrudates. In our previous study [12], it has been demonstrated that amount of average equivalent strain imposed by extrusion process increases as the contact area at an extrusion material and a die hole surface increases. Also the β phase in Al–Si–Fe alloys is refined by the friction between die and metal. Thus, β phase can be refined efficiently by using a die having a large contact surface between die and metal. In the present study, the ball surface area can be assumed as a contact surface between die and metal. The surface area of the balls in the small-ball extrusion, in the large-ball extrusion, and in the double-layered extrusion are 5.0 × 103, 5.0 × 103, and 10 × 103 mm2, respectively. Therefore, it is considered that the finest β phase was obtained in the double-layered extrudate because the double-layered ball-die has the largest contact surface between balls and metal.

Figure 6 shows the average lengths of the β phase in the variety of extrudates with respect to the distance from the surface of the extrudates. The size of the β phase in the conventional extrudate is finer near the surface and coarser in the center. On the other hand, the size of the β phase in all the ball-die extrudates are finer in the center. Therefore, it seems that higher strain was imposed in the center of the extrudate in the ball-die extrusion than near the surface. To investigate the reason why such high strain was imposed in the center of the ball-die extrudates, microstructure of a left billet after extrusion was observed.

Figure 7 shows the microstructures of the left billet after the small-ball extrusion in variety of positions shown in the figure. Before the extrusion (Fig. 7a), the β phase, the eutectic Si, and the Al matrix were still coarse same as the as-cast billet (Fig. 4a) because shear deformation was not imposed yet on the billet in the position. After passing through the gaps between the balls and the holder (Fig. 7b), the β phase was refined, and their lengths were in a range of 50–150 μm. The longitudinal direction of the β phase was aligned toward the hole of the shape-giving die. This refinement can be considered due to the shear deformation imposed on the billet at the gaps of the balls. Also, the dendritic structure of the Al matrix and the eutectic Si were also refined and dispersed homogeneously in the matrix. At the entrance of the shape-giving die (Fig. 7c), the β phase was aligned with the extrusion direction. After passing through the shape-giving die, the part shown in Fig. 7c comes to the surface of the extrudate. The lengths of the β phase near the surface were in a range of 50–100 μm. At the center of the spacer (Fig. 7d), the lengths of the β phase were approximately 20–50 μm, and most of them were finer than in other positions shown in Fig. 7. From this observation, the significant refinement in the center can be considered because of a collision of the extruded alloys from the balls and holder. Consequently, due to the collision of the metals during the extrusion, the high strain was imposed on the center of the ball-die extrudates, which results in the refinement of the β phase.

3.2 Tensile test

Figure 8 shows the stress–strain curves obtained from the as-cast Al-12 mass%Si-2 mass%Fe alloy extruded with the conventional, the small-ball, the large-ball, and the double-layered extrusions. The schematic image of the specimen is also shown in the figure. The as-cast alloy (Fig. 8a) shows the tensile strength of about 110 MPa and fractured after showing only 3% of elongation. All the extrudates (Fig. 8b–e) show a significant improvement in both strength and elongation. They show almost the same tensile strengths of about 180 MPa, and the elongations of more than 20%.

Tensile test results of a the as-cast Al-12 mass%Si-2 mass%Fe alloy, and Al-12 mass%Si-2 mass%Fe alloy extruded with b the conventional extrusion, c the small-ball extrusion, d the large-ball extrusion, and e the double-layered extrusion. The schematic image of the tensile specimen is also shown above the stress–strain curves

The elongations of the conventional extrudate (Fig. 8b), and the small-ball extrudate (Fig. 8c) are 20.5 and 22.7%, respectively. All the tests were conducted three times for each kind of specimen, and standard deviations in elongation of the conventional and the small-ball extrudates were approximately 0.39 and 0.90%. Thus, the differences in elongation between the two specimens, (b) and (c), are slight but significant. Consequently, it has been shown that the ball-die extrusion can improve elongation of alloys more in comparison with the conventional extrusion. The elongation of the large-ball extrudate (Fig. 8d) was 23.4%, which was almost the same as the one of the small-ball extrudate. Moreover, the double-layered extrudate shows the largest elongation of 26.0% among all the extrudates. The standard deviation of all the elongation of the extrudate were less than 1.5%, which is so small that the elongation differences among the extrudates can be considered as significant.

To investigate the fracture mechanism, fractured surfaces were observed. Figure 9 shows the fractured surface of the double-layered extrudate. The Al matrix fractured in a ductile manner with showing many fine dimples. On the other hand, in the center of Fig. 9, the β phase fractured in a brittle way with a large crack. Thus, it has been shown in this figure that the crack was initiated in the brittle β phase, and propagated along the β phase, leading to the fracture of a specimen.

As shown in Sect. 3.1, the average lengths of the β phase in the double-layered, the small-ball, the large-ball, and the conventional extrudates increase in this order. The total elongation increases in reverse order. Thus, it has been confirmed that the elongation clearly increases with the decrease in the length of the β phase. From the results, it has been demonstrated that the length of the β phase has a clear correlation with the elongation of the alloy. However, in the present Al-12 mass%Si-2 mass%Fe alloy, there are other factors which can affect the mechanical properties of the alloy, i.e., the eutectic Si and the grain size of the Al matrix. In the next section, the effect of the ball-die extrusion on the refinement of the eutectic Si and the grain size of the Al matrix are demonstrated.

3.3 Al matrix

Figure 10 shows the inverse pole figures obtained from the large-ball, and the double-layered extrudates. The analyzed positions are about 3 mm inside from surfaces of the extrudates in longitudinal sections. The black line shows the grain boundary and the black area shows the eutectic Si. The grain sizes of the Al matrix in the large-ball extrudate (Fig. 10a) and the double-layered extrudate (Fig. 10b) were 17.1 and 15.0 μm, with the standard deviations of 6.4 and 5.6 μm, respectively. Thus, same as the results of the β phase and the eutectic Si, as the surface area of the balls increases, the higher strain was imposed on the alloy and the smaller grain size of the Al matrix was obtained.

3.4 Eutectic Si

Figure 11 shows the average lengths of the eutectic Si measured in the longitudinal section of the conventional, the small-ball, the large-ball, and the double-layered extrudates. The bars on the graphs show the standard deviations. The average lengths of the eutectic Si in the conventional, the small-ball, the large-ball, and the double-layered extrudates increase in this order. The results coincide with the results of the size of the β phase. Thus, it can be understood that as the surface area of the balls increases, the imposed strain on the extrudates increases and the eutectic Si were also refined as well as the β phase.

It has been known that hard Si particles can deteriorate mechanical properties of materials [2]. Therefore, in the present study, not only the size of the β phase but also the size of the eutectic Si influences on the elongation of the alloy. However, it should be noted that the differences in size of the eutectic Si were small and they were only few micro meters in lengths, unlike that of the β phase. Therefore, the improvement in elongation of the alloy in the present study is reasonable to be considered mainly due to the refinement of the β phase.

4 Conclusions

Al-12 mass%Si-2 mass%Fe alloy was extruded with a specially designed ball-die. The obtained conclusions are as follows:

-

(1)

The β phase (Al9Si2Fe2) in the Al-12 mass%Si-2 mass%Fe alloy was refined by the newly developed ball-die extrusion. As the surface area of the balls used in the extrusion increases, the imposed strain on the alloy increases, and therefore, finer β phase was obtained. The finest β phase was obtained with the double-layered extrusion.

-

(2)

The ball-die extrudates show improvement in total elongation from the conventional extrudate. The largest elongation of 26.0% was obtained with the double-layered extrudate. As the length of the β phase decreases, the total elongation increases.

-

(3)

The size of the eutectic Si and the grain size of the Al matrix were slightly refined by the ball-die extrusion. The size of the eutectic Si and the grain size of the Al matrix were finer as the contact surface area at the balls and the alloy increases.

References

Wu XF, Zhang GA (2011) Effect of Sn addition on microstructure and dry sliding wear behaviors of hypereutectic aluminum–silicon alloy A390. J Mater Sci 46:7319–7327

Hu K, Ma X, Gao T, Xu Q, Qian Z, Wu Y, Liu X (2018) Morphological transformation mechanism of eutectic Si phases in Al–Si alloys by nano-AlNp. J Alloy Compd 765:113–120

Tang P, Li W, Wang K, Du J, Chen X, Zhao Y, Li W (2017) Effect of Al–Ti–C master alloy addition on microstructures and mechanical properties of cast eutectic Al–Si–Fe–Cu alloy. Mater Des 115:147–157

Becker H, Bergh T, Vullum PE, Leineweber A, Li Y (2019) Effect of Mn and cooling rates on α-, β- and δ-Al–Fe–Si intermetallic phase formation in a secondary Al–Si alloy. Materialia 5:100198

Okubo M, Kumai S, Ueda K (2007) Recycling of aluminum. J Min Mater Process Inst Jpn 123:850–854

Basak CB, Babu NH (2016) Morphological changes and segregation of β-Al9Fe2Si2 phase: a perspective from better recyclability of cast Al–Si alloys. Mater Des 108:277–288

Lin C, Wu S, Lu S, An P, Wan L (2013) Microstructure and mechanical properties of rheo-diecast hypereutectic Al–Si alloy with 2%Fe assisted with ultrasonic vibration process. J Alloy Compd 568:42–48

Osawa Y, Takamori S, Kimura T, Minagawa K, Kakisawa H (2007) Morphology of intermetallic compounds in Al–Si–Fe alloy and Its control by ultrasonic vibration. Mater Trans 48:2467–2475

Khalifa W, Tsunekawa Y, Okumiya M (2010) Effect of ultrasonic treatment on the Fe-intermetallic phases in ADC12 die cast alloy. J Mater Process Technol 210:2178–2187

Lu SZ, Hellawell A (1995) Modification of Al–Si alloys: microstructure, thermal analysis, and mechanisms. JOM 47:38–40

Kimura K, Ishii M, Yoshimura H (1994) Analysis of deformation, temperature, and microstructure of titanium alloys during Hot extrusion. Nippon Steel Tech Rep 62:69–73

Tomita K, Tokunaga T, Ohno M, Matsuura K (2016) Grain refinement and ductility improvement by hot extrusion using a heteromorphic die with small holes. Mater Trans 57:927–934

Acknowledgements

The authors would like to thank Prof. Kiyotaka Matsuura and Prof. Munekazu Ohno at Hokkaido University for their valuable comments and discussion. The authors are grateful to Prof. Seiji Miura and Prof. Ken-ichi Ikeda at Hokkaido University for their assistance in the tensile tests. This work was partially supported by Nanotechnology Platform Program of the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have declared that no competing interests exist.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tokunaga, T., Inubushi, H. Enhancement of ductility for Al–Si–Fe alloy by refining β phase with a novel ball-die extrusion. SN Appl. Sci. 1, 1334 (2019). https://doi.org/10.1007/s42452-019-1377-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-1377-4