Abstract

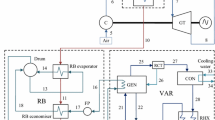

In this paper, a biomass gasification-based molten carbonate fuel cell (MCFC)-integrated advanced power system has been modelled and analyzed. The proposed system consisted of a biomass gasifier with hot gas cleaning equipment, a MCFC module, an indirectly heated air turbine and an organic Rankine cycle. Energetic, exergetic and economic (3E) analyses of the proposed power generation have been carried out. The effects of variation of operating and design parameters on the overall performances of the system have been showcased. Base case energetic and exergetic efficiency is found to be 38.49% and 32.7%, respectively. Exergetic analysis discloses that the highest exergy destruction takes place at gasifier (34.15%) followed by primary heat exchanger (16.15%), after burner (14.88%) and MCFC (13.80%). The proposed power system exhibits minimum unit cost of electricity of 0.17 $/kWh at current density of MCFC of 950 A/m2, fuel cell temperature of 973 K and secondary air blower pressure ratio of 1.6. At this operating condition, the plant gives a net output of 105.3 kW, its energy efficiency is 40.37% and exergy efficiency is 34.38%.

Similar content being viewed by others

Abbreviations

- A :

-

Transmission loss, %

- ASB:

-

Mass percentage of ash in biomass

- C :

-

Cost, $

- CB:

-

Mass percentage of carbon in biomass

- \( C_{\text{biomass}} \) :

-

Cost of biomass, $/GJ

- C EPCC :

-

Engineering, procurement and $ construction cost, $

- C EQP :

-

Total equipment cost, $

- CP :

-

Specific heat at constant pressure, kJ/kmol K

- CRF:

-

Capital recovery factor

- C TOC :

-

Total overnight cost, $

- CUF:

-

Capacity utilization factor

- D p :

-

Depletion potential

- E ADE :

-

Annualized delivery electricity, kWh

- Ex:

-

Specific exergy, kJ/kg

- EX:

-

Exergy, kW

- F :

-

Faraday constant, C/kmol

- F :

-

Annual inflation rate, %

- f EPCC :

-

Rectification factor associated with engineering, procurement and construction cost

- f TOC :

-

Rectification factor associated with preproduction cost, inventory capital and owner’s cost

- f TPC :

-

Rectification factor associated with process contingencies

- Δg :

-

Change in Gibbs function, kJ/kmol

- \( \Delta G \) :

-

Gibbs energy formation, kJ/kmol

- H :

-

Plant operating hour in a year, hour

- H :

-

Specific enthalpy, kJ/kmol

- \( \bar{h}_{f}^{o} \) :

-

Enthalpy of formation kJ/kmol

- HB:

-

Mass percentage of hydrogen in biomass

- HHV:

-

Higher heating value, kW

- I:

-

Annual interest rate, %

- I :

-

Current, A

- J :

-

Current density, A/m2

- J:

-

Nominal interest rate, %

- K :

-

Equilibrium constant

- K air :

-

Adiabatic gas constant of air

- LHV:

-

Lower heating value, kW

- LMTD:

-

Log mean temperature difference, K

- M :

-

Air requirement for biomass gasification, mole/mole of biomass

- m air :

-

Mass flow rate of air, kg/s

- Mc:

-

Moisture content kg/kg of biomass

- m f :

-

Mass flow rate of biomass, kg/s

- \( m_{\text{ORC}} \) :

-

Mass flow rate of organic fluid, kg/s

- \( m_{\text{oxidant}} \) :

-

Oxidant flow rate, kg/s

- n :

-

Lifespan of the system, years

- N :

-

Molar flow rate, kmol/s

- NB:

-

Mass percentage of nitrogen in biomass

- N cell :

-

Number of fuel cells

- N MCFC :

-

Number of MCFC stack

- OB:

-

Mass percentage of oxygen

- P :

-

Pressure, bar

- Q :

-

Heat rate, kW

- R :

-

Universal gas constant, kJ/kmol K

- R an :

-

Loss at anode, V

- R ca :

-

Loss at cathode, V

- R ohm :

-

Ohmic loss, V

- RP:

-

Pressure ratio

- S :

-

Specific entropy, kJ/kmol K

- SI:

-

Sustainability index

- T :

-

Temperature, K

- T cell :

-

Cell temperature, K

- T gas :

-

Gasifier temperature, K

- UCOE:

-

Unit cost of electricity, $/kWh

- V :

-

Voltage, V

- W :

-

Moisture content of biomass, mole/mole of biomass

- W :

-

Power, kW

- \( x_{\text{D}} \) :

-

Exergy destruction, %

- \( x_{\text{Loss}} \) :

-

Stack exergy loss, %

- Y :

-

Amount of individual gas component in syngas, mole

- AB:

-

After burner

- AT:

-

Air turbine

- B1:

-

Primary air blower

- B2:

-

Secondary air blower

- BIGCC:

-

Biomass-integrated gasification combined cycle

- CCHP:

-

Combined cooling, heating and power

- CON:

-

Condenser

- EES:

-

Engineering equation solver

- ESBC:

-

Electric specific biomass consumption

- GCE:

-

Gas cleaning equipment

- GT:

-

Gas turbine

- HEX1:

-

Primary heat exchanger

- HEX2:

-

Secondary heat exchanger

- HRVG:

-

Heat recovery vapour generator

- MCFC:

-

Molten carbonate fuel cell

- ODP:

-

Ozone depletion potential

- OLP:

-

Organic liquid pump

- ORC:

-

Organic Rankine cycle

- OVT:

-

Organic vapour turbine

- R245fa:

-

1,1,1,3,3-Pentafluoropropane

- SOFC:

-

Solid oxide fuel cell

- Β :

-

Correlation of the factor

- η :

-

Efficiency, %

- \( \xi \) :

-

Effectiveness

- \( \phi \) :

-

Exergy efficiency, %

- ADE:

-

Annualized delivered electricity

- an:

-

Anode

- B:

-

Air blower

- biom:

-

Biomass

- ca:

-

Cathode

- CAP:

-

Capital

- che:

-

Chemical

- Comp:

-

Component

- D :

-

Destruction

- env:

-

Environment

- EPCC:

-

Engineering, procurement and construction cost

- Ex:

-

Exergy

- f :

-

Fuel

- fg:

-

Flue gas

- G :

-

Gasifier

- HEX:

-

Heat exchanger

- in:

-

Inlet

- N :

-

Nernst

- ohm:

-

Ohmic

- out:

-

Outlet

- O&M:

-

Operation and maintenance

- p :

-

Product

- phy:

-

Physical

- r :

-

Reactant

- ref:

-

Reference

- sys:

-

System

- TOC:

-

Total overnight cost

- TPC:

-

Total plant cost

- w :

-

Water

- 1, 2, 3:

-

State points

References

Vatani A, Khazaeli A, Roshandel R, Panjeshahi MH (2013) Thermodynamic analysis of application of organic Rankine cycle for heat recovery from an integrated DIR-MCFC with pre-reformer. Energy Convers Manag 67:197–207. https://doi.org/10.1016/j.enconman.2012.11.019

Mamaghani AH, Najafi B, Shirazi A, Rinaldi F (2015) Exergetic, economic, and environmental evaluations and multi-objective optimization of a combined molten carbonate fuel cell-gas turbine system. Appl Therm Eng 77:1–11. https://doi.org/10.1016/j.applthermaleng.2014.12.016

Zhang X, Liu H, Ni M, Chen J (2015) Performance evaluation and parametric optimum design of a syngas molten carbonate fuel cell and gas turbine hybrid system. Renew Energy 80:407–414. https://doi.org/10.1016/j.renene.2015.02.035

Mahmoudi SMS, Ghavimi AR (2016) Thermoeconomic analysis and multi objective optimization of a molten carbonate fuel cell—supercritical carbon dioxide—organic Rankin cycle integrated power system using liquefied natural gas as heat sink. Appl Therm Eng 107:1219–1232. https://doi.org/10.1016/j.applthermaleng.2016.07.003

Samanta S, Ghosh S (2016) A thermo-economic analysis of repowering of a 250 MW coal fired power plant through integration of Molten Carbonate Fuel Cell with carbon capture. Int J Greenh Gas Control 51:48–55. https://doi.org/10.1016/j.ijggc.2016.04.021

Mehrpooya M, Sayyad S, Zonouz MJ (2017) Energy, exergy and sensitivity analyses of a hybrid combined cooling, heating and power (CCHP) plant with molten carbonate fuel cell (MCFC) and Stirling engine. J Clean Prod 148:283–294. https://doi.org/10.1016/j.jclepro.2017.01.157

Iaquaniello G, Mangiapane A (2006) Integration of biomass gasification with MCFC. Int J Hydrog Energy 31:399–404. https://doi.org/10.1016/j.ijhydene.2005.09.010

Devianto H, Sasongko D, Sempurna FI et al (2016) Effect of gas composition produced by gasification, on the performance and durability of molten carbonate fuel cell (MCFC). J Nat Gas Sci Eng 35:896–905. https://doi.org/10.1016/j.jngse.2016.08.075

Aminyavari M, Mamaghani AH, Shirazi A et al (2016) Exergetic, economic, and environmental evaluations and multi-objective optimization of an internal-reforming SOFC-gas turbine cycle coupled with a Rankine cycle. Appl Therm Eng 108:833–846. https://doi.org/10.1016/j.applthermaleng.2016.07.180

Mahmoudi SMS, Khani L (2016) Thermodynamic and exergoeconomic assessments of a new solid oxide fuel cell-gas turbine cogeneration system. Energy Convers Manag 123:324–337. https://doi.org/10.1016/j.enconman.2016.06.017

Meratizaman M, Monadizadeh S, Amidpour M (2014) Techno-economic assessment of high efficient energy production (SOFC-GT) for residential application from natural gas. J Nat Gas Sci Eng 21:118–133. https://doi.org/10.1016/j.jngse.2014.07.033

Roy D, Ghosh S (2017) Energy and exergy analyses of an integrated biomass gasification combined cycle employing solid oxide fuel cell and organic Rankine cycle. Clean Technol Environ Policy 19:1693–1709. https://doi.org/10.1007/s10098-017-1358-5

Eveloy V, Karunkeyoon W, Rodgers P, Al Alili A (2016) Energy, exergy and economic analysis of an integrated solid oxide fuel cell - gas turbine - organic Rankine power generation system. Int J Hydrogen Energy 41:13843–13858. https://doi.org/10.1016/j.ijhydene.2016.01.146

Zhang S, Liu H, Liu M et al (2017) An efficient integration strategy for a SOFC-GT-SORC combined system with performance simulation and parametric optimization. Appl Therm Eng 121:314–324. https://doi.org/10.1016/j.applthermaleng.2017.04.066

Soltani S, Mahmoudi SMS, Yari M, Rosen MA (2013) Thermodynamic analyses of a biomass integrated fired combined cycle. Appl Therm Eng 59:60–68. https://doi.org/10.1016/j.applthermaleng.2013.05.018

Zainal ZA, Ali R, Lean CH, Seetharamu KN (2001) Prediction of performance of a downdraft gasifier using equilibrium modeling for different biomass materials. Energy Convers Manag 42:1499–1515. https://doi.org/10.1016/S0196-8904(00)00078-9

Santhanam S, Schilt C, Turker B et al (2016) Thermodynamic modeling and evaluation of high efficiency heat pipe integrated biomass gasifier–solid oxide fuel cells–gas turbine systems. Energy 109:751–764. https://doi.org/10.1016/j.energy.2016.04.117

El-emam RS, Dincer I, Naterer GF (2011) Energy and exergy analyses of an integrated SOFC and coal gasification system. Int J Hydrog Energy 37:1689–1697. https://doi.org/10.1016/j.ijhydene.2011.09.139

Sanaye S, Katebi A (2014) 4E analysis and multi objective optimization of a micro gas turbine and solid oxide fuel cell hybrid combined heat and power system. J Power Sources 247:294–306. https://doi.org/10.1016/j.jpowsour.2013.08.065

Soltani S, Mahmoudi SMS, Yari M, Rosen MA (2013) Thermodynamic analyses of an externally fired gas turbine combined cycle integrated with a biomass gasification plant. Energy Convers Manag 70:107–115. https://doi.org/10.1016/j.enconman.2013.03.002

Arteaga-Pérez LE, Casas-Ledón Y, Pérez-Bermúdez R et al (2013) Energy and exergy analysis of a sugar cane bagasse gasifier integrated to a solid oxide fuel cell based on a quasi-equilibrium approach. Chem Eng J 228:1121–1132. https://doi.org/10.1016/j.cej.2013.05.077

Kotas TJ (1985) The exergy method of thermal plant analysis. Butterworths, London

NETL, Quality Guidelines for Energy Systems Studies (2011) Cost estimation methodology for NETL plant performance. NETL, US DOE

Meratizaman M, Monadizadeh S, Pourali O, Amidpour M (2015) High efficient-low emission power production from low BTU gas extracted from heavy fuel oil gasification, introduction of IGCC-SOFC process. J Nat Gas Sci Eng 23:1–15. https://doi.org/10.1016/j.jngse.2015.01.023

Trading Economics. https://tradingeconomics.com/india/indicators. Accessed 27 July 2017

Curletti F, Gandiglio M, Lanzini A et al (2015) Large size biogas-fed solid oxide fuel cell power plants with carbon dioxide management: technical and economic optimization. J Power Sources 294:669–690. https://doi.org/10.1016/j.jpowsour.2015.06.091

Samanta S, Ghosh S (2017) Techno-economic assessment of a repowering scheme for a coal fired power plant through upstream integration of SOFC and downstream integration of MCFC. Int J Greenh Gas Control 64:234–245. https://doi.org/10.1016/j.ijggc.2017.07.020

Taheri MH, Mosaffa AH, Farshi LG (2017) Energy, exergy and economic assessments of a novel integrated biomass based multi generation energy system with hydrogen production and LNG regasification cycle. Energy 125:162–177. https://doi.org/10.1016/j.energy.2017.02.124

Wang J-J, Yang K, Xu Z-L, Fu C (2015) Energy and exergy analyses of an integrated CCHP system with biomass air gasification. Appl Energy 142:317–327. https://doi.org/10.1016/j.apenergy.2014.12.085

Reyhani HA, Meratizaman M, Ebrahimi A et al (2016) Thermodynamic and economic optimization of SOFC-GT and its cogeneration opportunities using generated syngas from heavy fuel oil gasification. Energy 107:141–164. https://doi.org/10.1016/j.energy.2016.04.010

Mondal P, Ghosh S (2017) Exergo-economic analysis of a 1-MW biomass-based combined cycle plant with externally fired gas turbine cycle and supercritical organic Rankine cycle. Clean Technol Environ Policy 19:1475–1486. https://doi.org/10.1007/s10098-017-1344-y

Campanari S, Chiesa P, Manzolini G, Bedogni S (2014) Economic analysis of CO2 capture from natural gas combined cycles using Molten Carbonate Fuel Cells. Appl Energy 130:562–573. https://doi.org/10.1016/j.apenergy.2014.04.011

Nakyai T, Authayanun S, Patcharavorachot Y et al (2017) Exergoeconomics of hydrogen production from biomass air-steam gasification with methane co-feeding. Energy Convers Manag 140:228–239. https://doi.org/10.1016/j.enconman.2017.03.002

Rosen MA, Dincer I, Kanoglu M (2008) Role of exergy in increasing efficiency and sustainability and reducing environmental impact. Energy Policy 36:128–137. https://doi.org/10.1016/j.enpol.2007.09.006

Demirel Y (2002) Nonequilibrium thermodynamics: transport and rate processes in physical and biological systems. Elsevier, Amsterdam

Alauddin ZA (1996) Performance and characteristics of a biomass gasifer system. PhD Thesis. University of Wales, College of Cardif, UK

Gholamian E, Mahmoudi SMS, Zare V (2016) Proposal, exergy analysis and optimization of a new biomass-based cogeneration system. Appl Therm Eng 93:223–235. https://doi.org/10.1016/j.applthermaleng.2015.09.095

Milewski J, Wołowicz M, Lewandowski J (2013) Optimization of the working conditions of a laboratory size (100 cm2) Molten Carbonate Fuel Cell. ECS Trans 51:37–45

Haghighat A, Naja B, Shirazi A, Rinaldi F (2015) 4E analysis and multi-objective optimization of an integrated MCFC (molten carbonate fuel cell) and ORC (organic Rankine cycle) system. Energy 82:650–663. https://doi.org/10.1016/j.energy.2015.01.074

Ahmed S, Papadias D, Ahluwalia R, Hua T, Roh HS (2015) Performance and cost analysis for a 300 kW tri-generation Molten Carbonate Fuel Cell System. U.S. DOE Hydrogen and Fuel Cells Program and Vehicle Technologies Office, annual merit review and peer evaluation meeting. https://www.hydrogen.energy.gov/pdfs/review15/sa054_ahmed_2015_o.pdf

Eisentraut A, Brown A (2012) Technology roadmap: bioenergy for heat and power. International Energy Agency, Renewable Energy Division

Malek ABMA, Hasanuzzaman M, Rahim NA, Al Turki YA (2017) Techno-economic analysis and environmental impact assessment of a 10 MW biomass-based power plant in Malaysia. J Clean Prod 141:502–513. https://doi.org/10.1016/j.jclepro.2016.09.057

Rokni M (2014) Biomass gasification integrated with a solid oxide fuel cell and Stirling engine. Energy. https://doi.org/10.1016/j.energy.2014.01.078

Ghosh S (2018) Biomass-based distributed energy systems: opportunities and challenges. Sustain Energy Transp. https://doi.org/10.1007/978-981-10-7509-4_13

Chowdhury NR (2014) Advances in trends in woody biomass gasification. Energy engineering and management, Tecnico Lisboa

Craig KR, Mann MK (1996) Cost and performance analysis of biomass-based integrated gasification combined-cycle (BIGCC) power systems (No. NREL/TP-430-21657). National Renewable Energy Lab., Golden, CO (United States). https://www.nrel.gov/docs/legosti/fy97/21657.pdf

Zang G, Tejasvi S, Ratner A, Lora ES (2018) A comparative study of biomass integrated gasification combined cycle power systems: performance analysis. Bioresour Technol 255:246–256. https://doi.org/10.1016/j.biortech.2018.01.093

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical editor: Jose A. R. Parise.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Roy, D., Samanta, S. & Ghosh, S. Energetic, exergetic and economic (3E) investigation of biomass gasification-based power generation system employing molten carbonate fuel cell (MCFC), indirectly heated air turbine and an organic Rankine cycle. J Braz. Soc. Mech. Sci. Eng. 41, 112 (2019). https://doi.org/10.1007/s40430-019-1614-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-1614-1