Abstract

Ce/ZnO crystallites along with bare ZnO were prepared by solution free mechanochemical method and characterized with powder XRD, SEM, EDX, XPS, UV–Visible and Photoluminescence (PL) spectra. The visible light photocatalytic performance of these materials was investigated for H2 evolution with the aqueous 10vol% methanol solution under one sun conditions using solar simulator. X-ray diffraction data suggests the hexagonal wurtzite structure for Ce/ZnO crystallites and the incorporation of Ce4+ ion in ZnO is supported by the shifting of XRD peaks to lower Bragg angles that indicate lattice expansion. With the increase of Ce content in ZnO, the crystallite size of Ce/ZnO decreases and the specific surface area increases. UV–Visible spectra propose the decrease in optical band gap of Ce incorporated ZnO with the increase of Ce content up to 3 mol. %. The XPS analysis supports the incorporation of Ce4+ in Ce/ZnO. The PL spectra propose that, with the insertion of Ce ions into ZnO, intensity of UV emission band decreases that reflects the low recombination rate of photogenerated charge carriers, which is responsible for higher photocatalytic H2 production. The extent of hydrogen production is affected by calcination temperature of Ce/ZnO. 2 mol. % Ce incorporated ZnO calcined at 600 °C produces43 μmolh−1 g−1 of hydrogen.

Similar content being viewed by others

Introduction

Investigation of clean and efficient alternative for the fossil fuel is demanding area of research. Out of various non-conventional energy sources, H2 is the excellent alternative for fossil fuel because its use does not result in the emission of carbon dioxide, responsible for greenhouse effect. Now days, H2 production is done by several methods, but the most eco-friendly method is the photochemical water splitting over semiconductor materials. This method is more economical and reasonable because of the easy availability of sufficient quantity of sea water. In this regard, TiO2 has been extensively used over the last few decades because of its high chemical stability, nontoxic nature, economical and easy availability [1,2,3]. However, use of TiO2 is only effective towards the utilization of the UV light in the solar spectrum, and it suffers with high recombination rate of photogenerated electrons and holes, which leads to a low quantum yield and poor photocatalytic activity [4]. ZnO is one of the substitutes for TiO2 due to its similar optical properties, slightly lower band gap and excellent visible light response. In this contest bare ZnO is applied for the H2 production by means of photochemical water splitting [5,6,7]. In photochemical reaction, the production of H2 from water–methanol solution has a lower splitting energy than water (1.23 eV) and some reports propose that the overall methanol splitting reaction energy is 0.7 eV. However, it is difficult to overcome the redox potential for water or methanol decomposition using ZnO alone, therefore, various nonmetals are incorporated in ZnO [8,9,10]. To improve photocatalytic activity towards H2 production, ZnO is further modified by means of metal incorporation. In this concern, the photocatalytic hydrogen production from aqueous 10 vol % methanol solution using ZnO was investigated with aid of simultaneous metal deposition such as Ag, Au, Cu, Ni, Pd, Pt, and Rh. Out of various metals, the additions of copper and silver ions were effective for the improvement of photocatalytic H2 production from aqueous methanol solution. The photocatalytic H2 production using ZnO photocatalyst with aid of simultaneous deposition of Cu was approximately 130 times better than those obtained with bare ZnO [11]. Cu (0.1, 0.5, 1.0, and 5.0 mol. %) incorporated ZnO nanoparticles are prepared by a hydrothermal method were used for photocatalytic H2 production by means of decomposition of water–methanol mixture. Among the different samples, 1 mol. % Cu incorporated ZnO shows the highest H2 production (58.40 μmol) which is almost three times more than the bare ZnO (20.21 μmol) within 10 h [12]. Cu incorporated ZnO synthesized by sol gel method caused an enhancement in H2 production from 7.49 to 41.55 μmol g−1 which is due to the reduced recombination of electrons and holes during photocatalytic reaction [13]. Ag-doped ZnO nano composites were synthesized by a plasma-assisted approach and used as catalysts in the production of hydrogen by photo-reforming of alcoholic solutions, yielding a stable H2 evolution even by the sole use of simulated solar radiation. The silver NPs play a key role in promoting the photo-reforming of methanol/water solutions under UV–Visible irradiation. It is further noted that the highly dispersed Ag nanoparticles act as electron capturing centers to generate H2 [14]. Photocatalytic hydrogen evolution over Ag-doped ZnO was also tested by water splitting using ethanol as sacrificial agent [15]. Au/ZnO materials were used for the photocatalytic production of H2 from a water–ethanol solution under UV–Visible irradiation (λ > 300 nm). The efficiency of H2 production appears to be related to the size of Au nanoparticles [16]. ZnO nanowires with a gold loading of 10 wt.% is reported to be excellent photocatalyst toward the H2 production with deionized water containing 0.5 M Na2S and 0.03 M Na2SO3 as sacrificial reagents [17]. Recently, photocatalytic H2 production over Ca-doped ZnO [18], Zn/ZnO composite [19], Ni–ZnO/Polyaniline composite [20] were also reported. Till today, photocatalytic H2 production over rare earth metal incorporated ZnO is not reported by any research group. In this article, we report the efficient H2 production from a 10vol% methanol–water mixture by photochemical reaction using Ce/ZnO photocatalyst. Herein, we investigate the correlation between extent of H2 production and Ce concentration in Ce/ZnO, calcination temperature, crystallite size, optical band gap energy and oxygen vacancies of Ce/ZnO photocatalyst.

Materials and methods

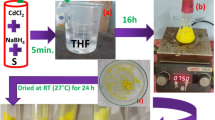

Ce/ZnO along with pure ZnO (for comparison) photocatalysts were prepared by our previously reported mechanochemical method for S/ZnO [21], using analytical grade zinc acetate di-hydrate (assay ≥ 99% Sigma-Aldrich), oxalic acid di-hydrate (assay 99.5%, Sigma-Aldrich), Cerium (IV) sulphate tetra-hydrate (Ce(SO4)2.4H2O) (assay ≥ 98%, Sigma-Aldrich) etc. Other required chemicals are of analytical grade, obtained from Merck Limited, Mumbai, India and were used without further purification. The 10vol% aqueous methanol solutions were prepared by using double distilled water.

Ce/ZnO of different Ce ion content (0.5%, 1%, 2%, and 3 mol. %) was prepared by two-step process. The first step is eco-friendly, solution free mechanochemical synthesis of oxalate precursor by solid state reaction and the second step is thermal decomposition of oxalate precursor to form Ce/ZnO nano crystals. In a typical synthesis, 0.995 mmol of zinc acetate di-hydrate and 1.20 mmol of oxalic acid di-hydrate taken in agate mortar and 0.005 mmol of Cerium (IV) sulphate tetrahydrate was added to the mixture as a source of Ce ion and mixture was hand ground for 10 min at room temperature. A solid state reaction occurs between zinc acetate di-hydrate and oxalic acid di-hydrate to form zinc oxalate and acetic acid byproduct. Acetic acid formed during the reaction act as internal solvent, which makes grinding process easier. Loss of acetic acid fumes becomes the driving force for the reaction. Oxalic acid also reacts with Cerium (IV) sulphate in acidic medium and expected to form Cerium (IV) oxalate. A thick semisolid paste of oxalate precursor was obtained within 20 min. Then the oxalate precursor was kept in oven at 70 °C for 30 min, so that most of the acetic acid byproduct goes off from the reaction mixture and semisolid gradually turns in to fine powder. Then oxalate precursor was calcined in muffle furnace at 600 °C for 2 h, to get 0.5%Ce/ZnO nano crystallites. Similar procedure was repeated to obtain 1%Ce/ZnO, 2%Ce/ZnO, 3%Ce/ZnO and bare ZnO using amounts summarized in Table 1. Ce/ZnO crystallites were characterized by X-ray diffractometer (D-8 Advance Bruker AXS), UV–Visible Spectrophotometer (UV-1601, Shimadzu), Photoluminescence (PL) spectra (Shimadzu, RF-5301PC), Scanning Electron Micrograph (SEM JEOL JSM-6360A) and Energy dispersive X-ray spectra (EDXS). X-ray Photoelectron spectra (XPS) were recorded with a V.G. Microtech (UK) unit ESCA 3000 spectrometer equipped with Mg Kα X-ray source (hυ = 1253.6 eV) and a hemispherical electron analyzer.

Photochemical splitting of 10vol% methanol–water was performed using a batch photo-reactor, under one sun conditions using solar simulator. An Oriel Instruments solar simulator equipped with a 300 W Xenon arc lamp system with an AM 1.5 cut-off filter as the irradiation source was employed. The above filter can be easily replaced with any other wavelength cut-off filter to alter the radiation wavelength regime. The reaction vessel was kept 20 cm away from the light source to ensure the one sun condition, as suggested by the Oriel solar simulator manual. This was further confirmed by the current, as measured by a lux meter. Cool air circulation was employed to maintain a constant temperature (27 °C) during irradiation. During each H2 production experiment, 25 mg of the photocatalysts were added to 30 mL of aqueous 10vol% methanol solution in the batch photoreactor and irradiated with visible light from solar simulator for specific period of time. The photocatalysts were continuously dispersed in the aqueous methanol solution by a magnetic stirrer during the irradiation. Gas analysis was carried out by regular sampling every hour, with a gas chromatograph (GC) equipped with a TCD detector (Agilent 7890) and high purity carrier gas.

Results and discussion

Visible light hydrogen production over bare ZnO and Ce/ZnO:

Figure 1 shows the H2 evolution by means of decomposition of a 10vol% of aqueous methanol solution over the bare ZnO and Ce/ZnO photocatalysts obtained at calcination temperature of 600 °C. The amount of H2 evolved over bare ZnO, 0.5%Ce/ZnO, 1%Ce/ZnO, 2%Ce/ZnO and 3%Ce/ZnO, are 1.2, 17, 29, 43 and 38 μmolh−1 g−1, respectively. This indicates that, Ce/ZnO is more active than bare ZnO towards the photocatalytic H2 production and with the increase in extent of Ce in ZnO, the activity increases up to 2%Ce/ZnO; whereas, when Ce amount is further increased to 3 mol. % then activity was found to decrease. To alter the morphology and crystallite size of Ce/ZnO, calcination temperature during photocatalyst synthesis was varied from 500 to 700 °C. Photocatalytic H2 production is greatly affected by calcination temperature at which Ce/ZnO is obtained.

The extent of H2 production increases with increase in calcination temperature of Ce/ZnO from 500 to 600 °C (Fig. 2). Further increase in calcination temperature from 600 to 700 °C found to be unfavorable for photocatalytic H2 evolution (Fig. 2). 2%Ce/ZnO calcined at 600 °C is the excellent photocatalyst for H2 production from the decomposition of water–methanol mixture. This is attributed to fact that crystalanity, morphology and crystallite size of semiconductor material is greatly affected by calcination temperature.

Characterization of Ce/ZnO and correlation with activity towards H2 production

The crystal structure and crystallite size of pure and Ce/ZnO was known by XRD analysis and results are depicted in Fig. 3a–e. Pure and Ce/ZnO (0.5%, 1%, 2%, and 3 mol. % Ce content) samples show prominent peaks at 2\(\theta\) of 31.82, 34.42, 36.39, 47.65, 56.63, 62.93, 66.43, 68.02 and 69.15 attributed to the (100), (002), (101), (102), (110), (103), (200), (112), and (201) planes, respectively, of hexagonal wurtzite structure of ZnO for the JCPDS No. 36-1451. However, no any XRD pattern corresponding to secondary phase of cerium oxide state was observed indicating the absence of CeO2 phase of dopant.

As compare the XRD pattern of bare ZnO (Fig. 3a) the XRD patterns of 0.5%Ce/ZnO (Fig. 3b), 1%Ce/ZnO (Fig. 3c), 2%Ce/ZnO (Fig. 3d) and 3%Ce/ZnO (Fig. 3e) are found to be broader and show lower Bragg angle shifting, which supports incorporation of Ce ions in to the lattice of ZnO. Similar observation is reported by Li et al. [22]. It is to be noted that, as the extent of Ce increases, the peak becomes more and more broad. This is due to fact that, the ionic radius of Ce4+ (97 pm) is slightly greater than that of Zn2+ (74 pm), which causes the partial distortion of hexagonal wurtzite structure of ZnO. The crystallite size (D) of bare ZnO and Ce/ZnO calculated from the full-width at half maximum (FWHM) of the most intense peaks (101) by using Deby Scherer equation and the specific surface areas are determined by using the relationship, S = 6/\(\rho\) D, where S is the specific surface area in m2 g−1, D is crystallite size in nm and \(\rho\) is the material density (for ZnO \(\rho\)= 5.61 \(\times\) 10–3 kg/cm3). The results are depicted in Fig. 4.

The crystallite size of Ce/ZnO is smaller than that of bare ZnO. And with the increase in Ce content the crystallite size was found to decrease. The specific surface area increase, as the content of Ce in Ce/ZnO increases (Fig. 4). The insertion of Ce into the ZnO lattice had a strong influence on H2 production by means of photochemical splitting of water–methanol mixture. This is due to fact that, the crystallite size of Ce/ZnO decreases and specific surface area increases with increase in concentration of Ce in ZnO. To correlate the optical absorption properties of the photocatalysts with its activity, the UV–Visible absorption spectra of pure and Ce/ZnO were investigated and results are shown in Fig. 5a–e. As compare to bare ZnO, \(\lambda\) max of Ce/ZnO shifts towards longer wavelength.

The λmax of bare ZnO, 0.5%Ce/ZnO, 1%Ce/ZnO, 2%Ce/ZnO and 3%Ce/ZnO was found to 373 (Fig. 5a), 373.5 (Fig. 5b), 373.7 (Fig. 5c), 376.3 (Fig. 5d) and 379.9 nm (Fig. 5e), respectively. It is also observed that, with increase in Ce content in ZnO, the absorption intensity decreases. It is well-known that optical absorption properties are associated with its optical energy gap (Eg). Hence, the optical energy gap is determined by Kubelka–Munk algorithm with tangent lines of the square root of F(R) against photon energy as shown in inset of Fig. 5f–j. The optical band gap of bare ZnO is found to be 3.18 eV (Fig. 5f), whereas, band gap of Ce/ZnO at different Ce content i.e. 0.5%, 1%, 2%, 3%, estimated from the tangent lines are 3.12 (Fig. 5g), 3.09 (Fig. 5h), 3.05 (Fig. 5i), and 3.01 eV (Fig. 5j), respectively. The narrowing of band gap benefits for the utilization of the light of longer wavelength which is ultimately useful for visible light photocatalytic H2 production. 2%Ce/ZnO has optimum band gap (3.05 eV) to absorb visible light and to minimize photo generated electron–hole recombination which is attributed to highest photocatalytic H2 production. Bare ZnO, 0.5%Ce/ZnO and 1%Ce/ZnO have larger band gap than the optimum value, makes difficult to absorb visible light, whereas, 3%Ce/ZnO has smaller band gap than optimum value, favors electron–hole recombination and hence shows less photocatalytic activities. Photoluminescence (PL) spectra of bare ZnO and Ce/ZnO were obtained at 330 nm excitation wavelength (Fig. 6a–e). Bare ZnO and Ce/ZnO shows two emission bands in the wavelength range of 350–550 nm, (a) Near band edge (NBE) or UV emission band (381 to 384 nm) and (b) green yellow emission band (410–500 nm). The UV emission band of bare ZnO and Ce/ZnO is attributed to the recombination of the free excitons of ZnO. As compare to bare ZnO, the intensity of UV emission band edge free excitonic PL signal decreases with increase in the extent of Ce in ZnO up to 2%Ce/ZnO (Fig. 6). This is mainly due to electronic capture of Ce4+ to become Ce3+ with a stable half-filled outer electronic structure. Therefore, the electrons captured by Ce4+ cannot be bound by surface oxygen vacancies and defects to further produce excitons, which decreases excitonic PL intensity [23]. The existence of Ce4+ in Ce/ZnO is ensured by XPS analysis of most active 2%Ce/ZnO calcined at 600 °C. Thus, the decrease in intensity of UV exitonic band with the increase in Ce content in ZnO supports less recombination of photogenerated electron–hole, which is attributed to more H2 production over Ce/ZnO.

As compare to bare ZnO, Ce/ZnO shows more intense green emission band at 410 to 500 nm. With the increase in extent of Ce in Ce/ZnO, the intensity of green emission band increases and its position shifts to the higher wavelength (Fig. 6a–e). It is well-known that the green yellow emission band around 410–500 nm originates from deep level (DL) defect emission associated with oxygen vacancies in ZnO lattices. Larger the content of oxygen vacancy or defect, stronger is the PL signal of green yellow emission [23]. It means, as the amount of Ce in ZnO increases the extent of oxygen vacancy or defect increases, which favors the photocatalytic H2 production. Because of more number of oxygen vacancies or defects in Ce/ZnO and less recombination of photo generated electron–hole, it shows higher photocatalytic H2 production than bare ZnO. Thus, 2%Ce/ZnO found to be most active photocatalyst towards the evolution of H2 (43 \(\upmu\)molh−1 g−1) due to lowest electron–hole recombination along with optimum oxygen vacancies.

To investigate the effect of calcination temperature on crystalanity and morphology of 2%Ce/ZnO, SEM–EDX analysis is carried out and results are highlighted in Fig. 7a–d. SEM analysis of 2%Ce/ZnO calcined at 500 °C shows the spherical, partially agglomerated particles (Fig. 7a). Due to agglomeration at 500 °C, less surface area is available which is attributed to less H2 production (17 \(\upmu\)molh−1 g−1). As the calcination temperature increased to 600 °C, 2%Ce/ZnO has good crystalanity and spongy morphology (Fig. 7b), which is favorable for H2 production (43 \(\upmu\)molh−1 g−1). When 2%Ce/ZnO calcined at 700 °C, in spite of spongy morphology and good crystalanity, (Fig. 7c), it shows less H2 production (14 \(\upmu\)molh−1 g−1) because of larger crystallite size and hence less specific surface area. The EDX of most active, 2%Ce/ZnO calcined at 600 °C, shows the presence of Ce in addition to Zn and O elements (Fig. 7d).

The chemical state of Ce ions in the ZnO lattice and their vibration states are ensured by XPS analysis of 2%Ce/ZnO and bare ZnO (for comparison) samples and results are correlated with activity of these materials towards photocatalytic H2 production. Figure 8a shows the full scan XPS of bare ZnO. High resolution XPS of Zn2p region of bare ZnO shows peaks centered at 1021 and 1044.1 eV are assigned to the 2p3/2 and 2p1/2 states, respectively (Fig. 8b), which can be ascribed to Zn2+ of ZnO lattice. Bare ZnO shows prominent and symmetric XPS peak in O1s region (Fig. 8c). Gaussian peak fitting shows two contributions: low energy prominent peak located at 530 eV and the high energy weak component centered at 531 eV.

Full scan XPS of 2%Ce/ZnO is represented in Fig. 9a. High resolution XPS of Zn2p region of 2%Ce/ZnO shows peaks centered at 1021.6 and 1044.9 eV, (Fig. 9b) which are slightly shifted to higher binding energy as compare to bare ZnO, which may be due to the smaller crystallite size of Ce/ZnO than that of bare ZnO. Figure 9c demonstrations XPS of O1s region of 2%Ce/ZnO which is asymmetric and composed of two components, low intensity peak centered at 530.13 eV and prominent peak centered at 531.54 eV. The former is associated with photoemission in O2− ions with valence state of lattice oxygen in ZnO and the latter is for lower valence oxygen i.e. surface adsorbed oxygen and O− [24]. Thus, the O1s peak of 2%Ce/ZnO is asymmetric and 531 component is more prominent than bare ZnO, which is indication of presence of more number of oxygen vacancies in 2%Ce/ZnO and attributed to more photocatalytic activity towards H2 production.

Higher number of oxygen vacancies are responsible to more H2 production [25]. High resolution XPS scan of Ce3d region shows prominent peaks centered at 890.6 and 897 eV are assigned to 3d5/2 state of Ce4+ ion and peaks centered at 906.7, 909.2 and 915.5 eV are assigned to 3d3/2 state of Ce4+ ion in ZnO surface (Fig. 9d). These Ce4+ dopant ions can capture photo generated electrons and restrict the electron–hole recombination. XPS of 2%Ce/ZnO and bare Zno were recorded with C1s reference with the binding energy 284.8 eV (Fig. 9e).

Mechanism of photocatalytic H2 production over Ce/ZnO:

When Ce/ZnO is irradiated with light, electron–hole pairs are generated in the conductance band and valence band, respectively (Fig. 10).

These electrons and holes participate in redox processes at the surface of photocatalyst. The splitting of water requires 237 kJ mol−1 of energy, whereas, methanol has a lower splitting energy relative to water. Hence, the photogenerated holes attack the methanol to form formaldehyde and hydrogen. Here, methanol also act as hole scavenger to increase the electron–hole separation [13]. Methanol is less polar (dipole moment is 1.69D) than water (dipole moment is 1.84D). When methanol is added to water it also weakens the strength of intermolecular hydrogen bonds of water molecules and makes water molecule free for photochemical splitting. Holes are the strong oxidizing agent and responsible for splitting of water to form H2. Photogenerated electrons reduce Ce4+ ion to the Ce3+ ion on the surface of ZnO. Hence Ce4+ ion dopant act as an electron sink, on the ZnO surface can enhance the separation of photogenerated electron–hole pairs and inhibit recombination of generated charges in photocatalysis.

Conclusions

UV–Visible spectra suggest that the 2%Ce/ZnO has optimum band gap (3.05 eV) to absorb visible light and to minimize photo generated electron–hole recombination which is attributed to highest photocatalytic H2 production. With increase in calcination temperature extent of H2 production was found to increases up to 600 °C. 2 mol. % Ce incorporated ZnO calcined at 600 °C produces 43 \(\upmu\)molh−1 \(\mathrm{g}\)−1 of H2 which is 35 times greater than bare ZnO (1.2 \(\upmu\)molh−1 \(\mathrm{g}\)−1) calcined at 600 °C. The higher hydrogen production over 2%Ce/ZnO as compare to bare ZnO is attributed to smaller crystallite size, greater surface area, more number of oxygen vacancies and reduction in recombination rate of photogenerated hole–electrons.

References

She, H., Ma, X., Chen, K., Liu, H., Huang, J., Wang, L., Wang, Q.: Photocatalytic H2 production activity of TiO2 modified by inexpensive Cu(OH)2 cocatalyst. J. Alloys Compd. 2020, 821 (2020). https://doi.org/10.1016/j.jallcom.2019.153239

Afanasiev, P.: Transfer of stored electrons between TiO2 polymorphs during photocatalytic H2 production in methanol–water medium. Appl. Catal. A Gen. 598, 117548 (2020). https://doi.org/10.1016/j.apcata.2020.117548

Divyasri, Y.V., Lakshmana Reddy, N., Lee, K., Sakar, M., Navakoteswara Rao, V., Venkatramu, V., Shankar, M.V., Gangi Reddy, N.C.: Optimization of N doping in TiO2 nanotubes for the enhanced solar light mediated photocatalytic H2 production and dye degradation. Environ. Pollut. 269, 116170 (2021). https://doi.org/10.1016/j.envpol.2020.116170

Reza Gholipour, M., Dinh, C.T., Béland, F., Do, T.O.: Nanocomposite heterojunctions as sunlight-driven photocatalysts for hydrogen production from water splitting. Nanoscale 7, 8187–8208 (2015). https://doi.org/10.1039/c4nr07224c

Luévano-Hipólito, E., Torres-Martínez, L.M.: Sonochemical synthesis of ZnO nanoparticles and its use as photocatalyst in H2 generation. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 226, 223–233 (2017). https://doi.org/10.1016/j.mseb.2017.09.023

Reli, M., Edelmannová, M., Šihor, M., Praus, P., Svoboda, L., Mamulová, K.K., Otoupalíková, H., Čapek, L., Hospodková, A., Obalová, L., Kočí, K.: Photocatalytic H2 generation from aqueous ammonia solution using ZnO photocatalysts prepared by different methods. Int. J. Hydrogen Energy. 40, 8530–8538 (2015). https://doi.org/10.1016/j.ijhydene.2015.05.004

Zhou, K., Liu, M., Ye, X., Zhu, Y., Liu, Z., Yang, Y., Dan, Y., Yuan, Y., Hou, H.: Electrospun highly crystalline ZnO nanofibers: super-efficient and stable photocatalytic hydrogen production activity. Chem. Select. 5, 6691–6696 (2020). https://doi.org/10.1002/slct.202001500

Kumar, S., Reddy, N.L., Kumar, A., Shankar, M.V., Krishnan, V.: Two dimensional N-doped ZnO-graphitic carbon nitride nanosheets heterojunctions with enhanced photocatalytic hydrogen evolution. Int. J. Hydrogen Energy. 43, 3988–4002 (2018). https://doi.org/10.1016/j.ijhydene.2017.09.113

Bhirud, A., Sathaye, S., Waichal, R., Park, C.J., Kale, B.: In situ preparation of N-ZnO/graphene nanocomposites: excellent candidate as a photocatalyst for enhanced solar hydrogen generation and high performance supercapacitor electrode. J. Mater. Chem. A. 3, 17050–17063 (2015). https://doi.org/10.1039/c5ta03955j

Mohamed, M.A., Zain, M., Jeffery Minggu, L., Kassim, M.B., Jaafar, J., Saidina Amin, N.A., Mastuli, M.S., Wu, H., Wong, R.J., Ng, Y.H.: Bio-inspired hierarchical hetero-architectures of in-situ C-doped g-C3N4 grafted on C, N co-doped ZnO micro-flowers with booming solar photocatalytic activity. J. Ind. Eng. Chem. 77, 393–407 (2019). https://doi.org/10.1016/j.jiec.2019.05.003

Gomathisankar, P., Hachisuka, K., Katsumata, H., Suzuki, T., Funasaka, K., Kaneco, S.: Enhanced photocatalytic hydrogen production from aqueous methanol solution using ZnO with simultaneous photodeposition of Cu. Int. J. Hydrogen Energy. 38, 11840–11846 (2013). https://doi.org/10.1016/j.ijhydene.2013.06.131

Choi, S., Do, J.Y., Lee, J.H., Ra, C.S., Kim, S.K., Kang, M.: Optical properties of Cu-incorporated ZnO (CuxZnyO) nanoparticles and their photocatalytic hydrogen production performances. Mater. Chem. Phys. 205, 206–209 (2018). https://doi.org/10.1016/j.matchemphys.2017.11.022

Manzoor, M.F., Ahmed, E., Ahmad, M., Ahmad, I., Rana, A.M., Ali, A., Ghouri, M.I., Manzoor, M.S., Aziz, M.T.: Enhanced photocatalytic activity of hydrogen evolution through Cu incorporated ZnO nano composites. Mater. Sci. Semicond. Process. 120, 105278 (2020). https://doi.org/10.1016/j.mssp.2020.105278

Simon, Q., Barreca, D., Bekermann, D., Gasparotto, A., MacCato, C., Comini, E., Gombac, V., Fornasiero, P., Lebedev, O.I., Turner, S., Devi, A., Fischer, R.A., Van Tendeloo, G.: Plasma-assisted synthesis of Ag/ZnO nanocomposites: first example of photo-induced H2 production and sensing. Int. J. Hydrogen Energy 36, 15527–15537 (2011). https://doi.org/10.1016/j.ijhydene.2011.09.045

Ahmad, I., Ahmed, E., Ahmad, M.: The excellent photocatalytic performances of silver doped ZnO nanoparticles for hydrogen evolution. SN Appl. Sci. 2019, 1 (2019). https://doi.org/10.1007/s42452-019-0331-9

Sampaio, M.J., Oliveira, J.W.L., Sombrio, C.I.L., Baptista, D.L., Teixeira, S.R., Carabineiro, S.A.C., Silva, C.G., Faria, J.L.: Photocatalytic performance of Au/ZnO nanocatalysts for hydrogen production from ethanol. Appl. Catal. A Gen. 518, 198–205 (2016). https://doi.org/10.1016/j.apcata.2015.10.013

Machín, A., Cotto, M., Duconge, J., Arango, J.C., Morant, C., Pinilla, S., Soto-Vázquez, L., Resto, E., Márquez, F.: Hydrogen production via water splitting using different Au@ZnO catalysts under UV–vis irradiation. J. Photochem. Photobiol. A Chem. 353, 385–394 (2018). https://doi.org/10.1016/j.jphotochem.2017.11.050

Ahmad, I., Ahmed, E., Ahmad, M., Akhtar, M.S., Basharat, M.A., Khan, W.Q., Ghauri, M.I., Ali, A., Manzoor, M.F.: The investigation of hydrogen evolution using Ca doped ZnO catalysts under visible light illumination. Mater. Sci. Semicond. Process. 105, 104748 (2020). https://doi.org/10.1016/j.mssp.2019.104748

Mangrulkar, P.A., Chilkalwar, A.A., Kotkondawar, A.V., Manwar, N.R., Antony, P.S., Hippargi, G., Labhsetwar, N., Trachtenberg, M.C., Rayalu, S.S.: Plasmonic nanostructured Zn/ZnO composite enhances carbonic anhydrase driven photocatalytic hydrogen generation. J. CO2 Util. 17, 207–212 (2017). https://doi.org/10.1016/j.jcou.2016.11.013

Nsib, M.F., Saafi, S., Rayes, A., Moussa, N., Houas, A.: Enhanced photocatalytic performance of Ni–ZnO/Polyaniline composite for the visible-light driven hydrogen generation. J. Energy Inst. 89, 694–703 (2016). https://doi.org/10.1016/j.joei.2015.05.001

Patil, A.B., Patil, K.R., Pardeshi, S.K.: Ecofriendly synthesis and solar photocatalytic activity of S-doped ZnO. J. Hazard. Mater. 183, 315–323 (2010). https://doi.org/10.1016/j.jhazmat.2010.07.026

Li, G., Lu, X., Zhao, W., Su, C., Tong, Y.: Controllable electrochemical synthesis of Ce4+-Doped ZnO nanostructures from nanotubes to nanorods and nanocages. Cryst. Growth Des. 8(4), 1276–1281 (2008). https://doi.org/10.1021/cg7009995

Liqiang, J., Yichun, Q., Baiqi, W., Shudan, L., Baojiang, J., Libin, Y., Wei, F., Honggang, F., Jiazhong, S.: Review of photoluminescence performance of nano-sized semiconductor materials and its relationships with photocatalytic activity. Sol. Energy Mater. Sol. Cells. 90, 1773–1787 (2006). https://doi.org/10.1016/j.solmat.2005.11.007

Brundle, C.R., Bickley, R.I.: Photoemission and Auger spectroscopy studies of the interaction of oxygen with zinc. J. Chem. Soc. Faraday Trans. Mol. Chem. Phys. 75, 1030–1046 (1979). https://doi.org/10.1039/F29797501030

Huerta-Flores, A.M., Luévano-Hipólito, E., Torres-Martínez, L.M., Torres-Sánchez, A.: Photocatalytic H2 production and CO2 reduction on Cu, Ni-doped ZnO: effect of metal doping and oxygen vacancies. J. Mater. Sci. Mater. Electron. 30, 18506–18518 (2019). https://doi.org/10.1007/s10854-019-02204-0

Acknowledgements

Ashokrao B. Patil is grateful to Indian Academy of Sciences Bengaluru, Indian National Science Academy, New Delhi and The National Academy of Sciences, Allahabad (IASc-INSA-NASI) for awarding SRF. Authors are also thankful to Professor Satish K. Pardeshi, Savitribai Phule Pune University; Pune (India), National Chemical Laboratories; Pune (India) and DST-FIST Research Laboratory, K. M. C. College, Khopoli for providing the necessary research facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Patil, A.B., Jadhav, B.D. & Bhoir, P.V. Efficient photocatalytic hydrogen production over Ce/ZnO from aqueous methanol solution. Mater Renew Sustain Energy 10, 14 (2021). https://doi.org/10.1007/s40243-021-00199-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-021-00199-5