Abstract

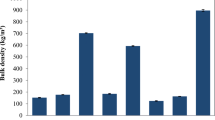

Mankind’s quest to reduce its dependency on fossil fuel involves biomass as a promising alternative. However, direct application of raw biomass faces problems such as high moisture content, low heating value, and poor grindability. Pyrolysis is one of the pre-treatment methods to improve biomass properties particularly its energy density. This study is aimed at investigating the pyrolysis of oil palm trunk (OPT) into biocoal and its suitability for solid fuel applications in terms of slagging and fouling tendencies, bulk density, proximate and ultimate analysis, higher heating value, energy densification ratio, and mass and energy yield. The biocoal was produced using a top-lit, updraft reactor with a peak temperature of 550 °C and fixed air flowrate of 4.63 L/min. The bulk density of OPT biocoal was 87.7 kg/m3 which is 4.63% lower than that of original OPT due to the increased porosity. The elemental composition of our biocoal resembles lignite. The volatile matter content decreased by a factor of 1.87 while the fixed carbon content and higher heating value (HHV) increased from 4.29 to 30.9% and from 14.5 to 19.6 MJ/kg, respectively. The HHV of biocoal increased by a factor of 1.36 relative to that of raw OPT; however, the resulting energy yield was low (37.6 ± 1.9%) due to a low biocoal yield of 27.8 ± 1.4%. The ash content increased by a factor of 1.5, resulting in an ash content of 27.8 wt% for biocoal. This increment may exacerbate the slagging and fouling propensity in furnaces and boilers as indicated by the slagging and bed agglomeration index which increased from 2.0 to 5.2 and from 0.4 to 0.7, respectively. Demineralization, a lower pyrolysis temperature and subsequent briquetting of OPT biocoal are suggested to improve its fuel properties for co-combustion in coal-firing power plants.

Similar content being viewed by others

References

Matali S, Rahman NA, Idris SS, Yaacob N, Alias AB (2016) Lignocellulosic biomass solid fuel properties enhancement via torrefaction. Procedia Eng 148:671–678

Vassilev SV, Baxter D, Andersen LK, Vassileva CG (2010) An overview of the chemical composition of biomass. Fuel 89:913–933

Lau HS, Ng HK, Gan S, Jourabchi SA (2018) Torrefaction of oil palm fronds for co-firing in coal power plants. Energy Procedia 144:75–81

Abdullah H, Jie WS, Yusof N, Isa IM (2016) Fuel and ash properties of biochar produced from microwave-assisted carbonisation of oil palm trunk core. J Oil Palm Res 28:81–92

Tortosa Masiá AA, Buhre BJP, Gupta RP, Wall TF (2007) Characterising ash of biomass and waste. Fuel Process Technol 88:1071–1081

Mohamad Daud AR (2015) Energy densified biochar production from slow pyrolysis of reed canary grass. ARPN J Eng Appl Sci 10:7196–7201

Nsamba HK, Hale SE, Cornelissen G, Bachmann RT (2015) Sustainable technologies for small-scale biochar production-a review. J Sustain Bioenergy Syst 5:10–31

Milhé M, van de Steene L, Haube M, Commandré JM, Fassinou WF, Flamant G (2013) Autothermal and allothermal pyrolysis in a continuous fixed bed reactor. J Anal Appl Pyrolysis 103:102–111

Li D, Berruti F, Briens C (2014) Autothermal fast pyrolysis of birch bark with partial oxidation in a fluidized bed reactor. Fuel 121:27–38

Inguanzo M, Menéndez J, Fuente E, Pis J (2001) Reactivity of pyrolyzed sewage sludge in air and CO2. J Anal Appl Pyrolysis 58–59:943–954

Wang J, Huang L, Yang R, Zhang Z, Wu J, Gao Y, Wang Q, O'Hare D, Zhong Z (2014) Recent advances in solid sorbents for CO2 capture and new development trends. Energy Environ Sci 7:3478–3518

Emami Taba L, Irfan MF, Wan Daud WAM, Chakrabarti MH (2012) The effect of temperature on various parameters in coal, biomass and CO-gasification: a review. Renew Sust Energ Rev 16:5584–5596

Chen YH, Chang CC, Chang CY, Yuan MH, Ji DR, Shie JL, Lee CH, Chen YH, Chang WR, Yang TY, Hsu TC, Huang M, Wu CH, Lin FC, Ko CH (2017) Production of a solid bio-fuel from waste bamboo chopsticks by torrefaction for cofiring with coal. J Anal Appl Pyrolysis 126:315–322

Rago YP, Surroop D, Mohee R (2018) Assessing the potential of biofuel (biochar) production from food wastes through thermal treatment. Bioresour Technol 248:258–264

Sulaiman MH, Uemura Y, Azizan MT (2016) Torrefaction of empty fruit bunches in inert condition at various temperature and time. Procedia Eng 148:573–579

Umar MS, Jennings P, Urmee T (2013) Strengthening the palm oil biomass renewable energy industry in Malaysia. Renew Energy 60:107–115

Pang TW, Lee MT (2013) In: Pogaku R, Sarbatly RH (eds) Advances in biofuels. Springer, US, pp 15–26. https://doi.org/10.1007/978-1-4614-6249-1_2

Sukiran MA, Abnisa F, Wan Daud WMA, Abu Bakar N, Loh SK (2017) A review of torrefaction of oil palm solid wastes for biofuel production. Energy Convers Manag 149:101–120

Shafie SM, Mahlia TMI, Masjuki HH, Ahmad-Yazid A (2012) A review on electricity generation based on biomass residue in Malaysia. Renew Sust Energ Rev 16:5879–5889

Deris, R. R. R., Sulaiman, M. R., Darus, F. M., Mahmud, M. S. & Bakar, N. A.(2006) Pyrolysis of oil palm trunk (OPT). Proc 20th Symp Malayisan Chem Eng (SOMChE) 2006 245–250

Lim KO, Lim KS (1992) Carbonisation of oil palm trunks at moderate temperatures. Bioresour Technol 40:215–219

Chin KL, H’ng PS, Go WZ, Wong WZ, Lim TW, Maminski M, Paridah MT, Luqman AC (2013) Optimization of torrefaction conditions for high energy density solid biofuel from oil palm biomass and fast growing species available in Malaysia. Ind Crop Prod 49:768–774

Abnisa F, Arami-Niya A, Wan Daud WMA, Sahu JN, Noor IM (2013) Utilization of oil palm tree residues to produce bio-oil and bio-char via pyrolysis. Energy Convers Manag 76:1073–1082

Nsamba HK, Hale SE, Cornelissen G, Bachmann RT (2014) Improved gasification of rice husks for optimized biochar production in a top lit updraft gasifier. J Sustain Bioenergy Syst 4:225–242

ASTM E873–82 (2013) Standard test method for bulk density of densified particulate biomass fuels. ASTM International, West Conshohocken, PA (2013). https://doi.org/10.1520/E0873-82R13

Koerner, K. (2012) Determination of porosity of rock samples, torrefied biomass, activated carbon and proppant sand for usage in wastewater treatment and simulation of oil reservoir analysis using the Barnes method and helium porosimetry. 4–9

Pham XH, Piriou B, Salvador S, Valette J, Van de Steene L (2018) Oxidative pyrolysis of pine wood, wheat straw and miscanthus pellets in a fixed bed. Fuel Process Technol 178:226–235

Atnaw SM, Sulaiman SA, Yusup S (2013) Syngas production from downdraft gasification of oil palm fronds. Energy 61:491–501

McAllister S, Chen J-Y, Fernandez-Pello AC (2011) Fundamentals of combustion processes. Springer-Verlag, New York. https://doi.org/10.1007/978-1-4419-7943-8

ASTM D7582–10 (2010) Standard test methods for proximate analysis of coal and coke by macro thermogravimetric analysis. ASTM International, West Conshohocken. https://doi.org/10.1520/D7582-10

Cai J, He Y, Yu X, Banks SW, Yang Y, Zhang X, Yu Y, Liu R, Bridgwater AV (2017) Review of physicochemical properties and analytical characterization of lignocellulosic biomass. Renew Sust Energ Rev 76:309–322

ASTM D5865–13 (2013) Standard test method for gross calorific value of coal and coke. ASTM International, West Conshohocken. https://doi.org/10.1520/D5865-13

Parikh J, Channiwala SA, Ghosal GK (2005) A correlation for calculating HHV from proximate analysis of solid fuels. Fuel 84:487–494

Teixeira P, Lopes H, Gulyurtlu I, Lapa N, Abelha P (2012) Evaluation of slagging and fouling tendency during biomass co-firing with coal in a fluidized bed. Biomass Bioenergy 39:192–203

Liu Z, Han G (2015) Production of solid fuel biochar from waste biomass by low temperature pyrolysis. Fuel 158:159–165

Vamvuka D, Zografos D (2004) Predicting the behavior of ash from agricultural wastes during combustion. Fuel 83:2051–2057

Conag AT, Villahermosa JER, Cabatingan LK, Go AW (2018) Energy densification of sugarcane leaves through torrefaction under minimized oxidative atmosphere. Energy Sustain Dev 42:160–169

Phyllis2 - coal, lignite. ECN (1997). Available at: https://www.ecn.nl/phyllis2/Biomass/View/2847. (Accessed: 28th August 2018)

Costen, P., Lockwood, F. C. & Ou, J. J.(1994) Analysis of solid waste fuels. APAS Clean Coal Technology 32 . Available at: https://www.ecn.nl/phyllis2/Biomass/View/958. (Accessed: 28th August 2018)

Kajina W, Rousset P, Chen WH, Sornpitak T, Commandré JM (2018) Coupled effect of torrefaction and blending on chemical and energy properties for combustion of major open burned agriculture residues in Thailand. Renew Energy 118:113–121

Girón RP, Ruiz B, Fuente E, Gil RR, Suárez-Ruiz I (2013) Properties of fly ash from forest biomass combustion. Fuel 114:71–77

Alias NB, Ibrahim N, Hamid MKA, Hasbullah H, Ali RR, Kasmani RM (2015) Investigation of oil palm wastes’ pyrolysis by thermo-gravimetric analyzer for potential biofuel production. Energy Procedia 75:78–83. https://doi.org/10.1016/j.egypro.2015.07.141

Chen J, Fan X, Jiang B, Mu L, Yao P, Yin H, Song X (2015) Pyrolysis of oil-plant wastes in a TGA and a fixed-bed reactor: thermochemical behaviors, kinetics, and products characterization. Bioresour Technol 192:592–602

Czajka K, Kisiela A, Moroń W, Ferens W, Rybak W (2016) Pyrolysis of solid fuels: thermochemical behaviour, kinetics and compensation effect. Fuel Process Technol 142:42–53

Asadieraghi M, Wan Daud WMA (2014) Characterization of lignocellulosic biomass thermal degradation and physiochemical structure: effects of demineralization by diverse acid solutions. Energy Convers Manag 82:71–82

Brebu M, Vasile C (2010) Thermal degradation of lignin – a review. Cellul Chem Technol 44:353–363

Shen DK, Gu S, Luo KH, Wang SR, Fang MX (2010) The pyrolytic degradation of wood-derived lignin from pulping process. Bioresour Technol 101:6136–6146

Mi B, Liu Z, Hu W, Wei P, Jiang Z, Fei B (2016) Investigating pyrolysis and combustion characteristics of torrefied bamboo, torrefied wood and their blends. Bioresour Technol 209:50–55

Fierro V, Torné-Fernández V, Montané D, Celzard A (2005) Study of the decomposition of kraft lignin impregnated with orthophosphoric acid. Thermochim Acta 433:142–148

Channiwala SA, Parikh PP (2002) A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 81:1051–1063

Pahla G, Mamvura TA, Ntuli F, Muzenda E (2017) Energy densification of animal waste lignocellulose biomass and raw biomass. South African J Chem Eng 24:168–175

Acharya B, Sule I, Dutta A (2012) A review on advances of torrefaction technologies for biomass processing. Biomass Convers Biorefinery 2:349–369

Valix M, Katyal S, Cheung WH (2017) Combustion of thermochemically torrefied sugar cane bagasse. Bioresour Technol 223:202–209

Chen G, Andries J, Luo Z, Spliethoff H (2003) Biomass pyrolysis/gasification for product gas production: the overall investigation of parametric effects. Energy Convers Manag 44:1875–1884

Kow K, Mun LY, Yusoff RS (2015) Gel synthesized from oil palm boiler ash. J Miner Met Mater Eng 1:14–18

Abdullah N, Sulaiman F, Gerhauser H (2011) Characterisation of oil palm empty fruit bunches for fuel application. J Phys Sci 22:1–24

Karim MR, Hashim H, Abdul Razak H, Yusoff S (2017) Characterization of palm oil clinker powder for utilization in cement-based applications. Constr Build Mater 135:21–29. https://doi.org/10.1016/j.conbuildmat.2016.12.158

Loh SK (2017) The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers Manag 141:285–298

Acharya B, Dutta A, Mahmud S, Tushar M, Leon MA (2014) Analysis of poultry litter, willow and oats for combustion in boilers. J Biomass to Biofuel 1

Pintana P, Tippayawong N (2016) Predicting ash deposit tendency in thermal utilization of biomass. Engl J 20:15–24

Russell NV, Wigley F, Williamson J (2002) The roles of lime and iron oxide on the formation of ash and deposits in PF combustion. Fuel 81:673–681

Febrero L, Granada E, Regueiro A, Míguez JL (2015) Influence of combustion parameters on fouling composition after wood pellet burning in a lab-scale low-power boiler. Energies 8:9794–9816

Bryers RW (1996) Fireside slagging, fouling, and high-temperature corrosion of heat-transfer surface due to impurities in steam-raising fuels. Prog Energy Combust Sci 22:29–210

Pronobis M (2005) Evaluation of the influence of biomass co-combustion on boiler furnace slagging by means of fusibility correlations. Biomass Bioenergy 28:375–383

Lin Y, Ma X, Ning X, Yu Z (2015) TGA–FTIR analysis of co-combustion characteristics of paper sludge and oil-palm solid wastes. Energy Convers Manag 89:727–734

Jiang L, Hu S, Sun LS, Su S, Xu K, He LM, Xiang J (2013) Influence of different demineralization treatments on physicochemical structure and thermal degradation of biomass. Bioresour Technol 146:254–260

Aslam U, Ramzan N, Iqbal T, Kazmi M, Ikhlaq A (2016) Effect of demineralization on the physiochemical structure and thermal degradation of acid treated indigenous rice husk. Pol J Chem Technol 18:117–121

Kasim, N. N. et al. (2016) Demineralization of oil palm empty fruit bunch (EFB) intended as high quality bio-oil feedstock. 4th IET Clean Energy Technol. Conf (CEAT) 2016 1–6 . doi:https://doi.org/10.1049/cp.2016.1364

Acknowledgments

The help and assistance from various government and non-governmental organizations is gratefully acknowledged.

Funding

The authors express their gratitude to PRGS/1/2014/TK05/UPM/02/2 under the Ministry of Higher Education for financial support. Apart from that, we also would like to thank the Engineering and Physical Sciences Research Council for the partial funding of this research through the BEFEW project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nudri, N.A., Bachmann, R.T., Ghani, W.A.W.A.K. et al. Characterization of oil palm trunk biocoal and its suitability for solid fuel applications. Biomass Conv. Bioref. 10, 45–55 (2020). https://doi.org/10.1007/s13399-019-00419-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00419-z