Abstract

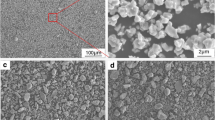

The Ti/TiBCN composite coatings were fabricated on the substrate of Ti6Al4V alloy by laser cladding. The effects of TiBCN content on the microstructre, microhardness, corrosion resistance and tribological properties of the composite coatings were studied. The results showed that, when the TiBCN content was 60 wt%, the composite coatings were mainly composed of the dendritic and rod-shaped TiBCN phases, small white lump TiC phases, fine lamellar TiN phases, small and scattered white block TiB2 phases, In addition, there was a small quantity of short whisker Al3Ti phases and uniform layer block TiAl phases. Furhtermore, the maximum microhardness was 1596 HV, which was about 4.6 folds greater than that of the substrate; the corrosion potential (Ecorr) reached − 1.258 V and the corrosion current density (Icorr) was 4.035 × 10−5 A/cm2, which was one order lower than that of the substrate (1.172 × 10−4 A/cm2); the worn surface was relatively smooth and the mass loss (1.22 g) was only 9/50 of that of the substrate (6.71 g).

Similar content being viewed by others

References

Y.M. Chi, G.C. Gu, H.J. Yu, C.Z. Chen, Opt. Laser. Eng. 100, 23 (2018)

X. Su, W. Tao, Y. Chen, X. Chen, Z. Tian, Mater. Lett. 195, 228 (2017)

M. Nabhani, R.S. Razavi, M. Barekat, Opt. Laser. Eng. 100, 265 (2018)

C.T. Kwok, H.C. Man, F.T. Cheng, K.H. Lo, Surf. Coat. Tech. 291, 189 (2016)

X.Y. Jiao, J. Wang, C.M. Wang, Z.Q. Gong, X.X. Pang, S.M. Xiong, Opt. Laser. Eng. 110, 163 (2018)

S. Matthews, L.M. Berger, J. Alloy. Compd. 770, 1078 (2019)

D.H. Zhang, D.J. Kong, Appl. Surf. Sci. 457, 69 (2018)

J.S. Meng, G. Jin, X.P. Shi, Appl. Surf. Sci. 431, 135 (2018)

D.B. Wei, P.Z. Zhang, Z.J. Yao, X.H. Chen, F.K. Li, Vacuum 155, 233 (2018)

C.M. Lin, W.Y. Kai, C.Y. Su, C.N. Tsai, Y.C. Chen, J. Alloy. Compd. 717, 197 (2017)

J.L. Daure, M.J. Carrington, P.H. Shipway, D.G. McCartney, D.A. Stewartb, Surf. Coat. Tech. 350, 40 (2018)

W. Guo, J. Chu, W. Nie, Geotext. Geomembranes 46, 625 (2018)

M. Staszuk, D. Pakuła, G. Chladek, M. Pawlyta, M. Pancielejko, P. Czaja, Vacuum 154, 272 (2018)

D. Hui, K. Endo, K. Yamamura, Int. J. Mach. Tools Manuf 115, 38 (2017)

J. Gäbler, S. Pleger, Int. J. Mach. Tools Manuf 50, 420 (2010)

Y.C. Kim, S.J.L. Kang, Int. J. Mach. Tools Manuf 51, 565 (2011)

C. Czettl, J. Thurner, U. Schleinkofer, Int. J. Refract. Met. H. 71, 330 (2018)

T. Lutzler, T.V.J. Charpentier, R. Barker, S. Soltanahmadi, W. Taleb, C. Wang, A. Alejo-Rodriguez, E. Perre, H. Schneider, A. Nevillea, Mater. Chem. Phys. 216, 272 (2018)

A. Alcantara-Garcia, A. Garcia-Casas, A. Jimenez-Morales, Prog. Org. Coat. 124, 267 (2018)

W. Gao, C. Chang, G. Li, Y. Xue, J. Wang, Z. Zhang, X. Lin, Optik. 178, 950 (2019)

Y. Feng, K. Feng, C. Yao, Z. Li, J. Sun, Mater. Des. 157, 258 (2018)

G.H. Meng, X. Lin, H. Xie, T.M. Yue, X. Ding, L. Sun, M. Qi, Mater. Des. 108, 157 (2016)

D. Shu, Z.G. Li, K. Zhang, C.W. Yao, D.Y. Li, Z.B. Dai, Mater. Lett. 195, 178 (2017)

E. Altus, E. Konstantino, Mater. Sci. Eng., A 302, 100 (2001)

X.Y. Liu, P.K. Chu, C.X. Ding, Mater. Sci. Eng. R 47, 49 (2004)

X.Y. Jiao, C.M. Wang, Z.Q. Gong, G.M. Wang, H.F. Sun, H.R. Yang, Surf. Coat. Technol. 325, 643 (2017)

J.F. Li, L. Li, F.H. Stott, Acta Mater. 52, 4385 (2004)

X.Y. Jiao, C.M. Wang, Z.Q. Gong, G.M. Wang, H.F. Sun, H.R. Yang, Surf. Coat. Technol. 325, 643 (2017)

S. Kumar, A. Mandal, A. Das, A. Dixit, Surf. Coat. Technol. 349, 37 (2018)

Y.H. Lv, J. Li, Y.F. Tao, L.F. Hu, Appl. Surf. Sci. 402, 478 (2017)

Y. Sun, M. Hao, Opt. Laser Eng. 50, 985 (2012)

H. Liu, X. Zhang, Y. Jiang, R. Zhou, J. Alloy. Compd. 670, 268 (2016)

Y. Lei, R. Sun, J. Lei, Y. Tang, W. Niu, Opt. Laser Eng. 48, 899 (2010)

Y. Lin, J. Yao, Y. Lei, H. Fu, L. Wang, Opt. Laser Eng. 86, 216 (2016)

J. Li, Z. Yu, H. Wang, Thin Solid Films 519, 4804 (2011)

J.L. Li, G.Y. Cai, H.S. Zhong, Y.X. Wang, J.M. Chen, Rare Met. 36, 858 (2017)

Y. Li, P. Zhang, P. Bai, L. Wu, B. Liu, Z. Zhao, Surf. Coat. Technol. 334, 142 (2018)

Y.X. Li, P.F. Zhang, P.K. Bai, Z.Y. Zhao, Materials 11, 1551 (2018)

M.O.H. Amuda, E.T. Akinlabi, M. Moolla, Mater. Today 4, 763 (2017)

Y.G. Han, Y. Yang, L. Wang, X.G. Chen, Z.H. Chu, X.N. Zhang, Y.C. Dong, Z. Liu, D.R. Yan, J.X. Zhang, C.G. Li, Appl. Surf. Sci. 431, 48 (2018)

L. Chen, S.L. Bai, Appl. Surf. Sci. 437, 1 (2018)

L. Yang, Z. Li, Y. Zhang, S. Wei, F. Liu, Appl. Surf. Sci. 435, 1187 (2018)

S. Sun, H. Fu, X. Ping, J. Lin, Y. Lei, W. Wu, J. Zhou, Appl. Surf. Sci. 455, 160 (2018)

Z. Li, R. Xu, Z. Zhang, I. Kucukkoc, Int. J. Mach. Tools Manuf 126, 1 (2018)

Y.X. Li, J.D. Hu, H.Y. Wang, Z.X. Guo, Adv. Eng. Mater. 9, 689 (2017)

Y.X. Li, J.D. Hu, H.Y. Wang, Z.X. Guo, Adv. Eng. Mater. 9, 689 (2010)

Y. Guo, Y. Zhang, Z. Li, S. Wei, T. Zhang, L. Yang, S. Liu, Surf. Coat. Technol. 334, 471 (2018)

M. Stern, A.L. Geary, J. Electrochem. Soc. 104, 56 (1957)

J. Park, H.S. Han, J. Park, H. Seo, J. Edwards, Y.C. Kim, M.R. Ok, H.K. Seok, H. Jeon, Appl. Surf. Sci. 448, 424 (2018)

D. Hawelka, J. Stollenwerk, N. Pirch, K. Wissenbach, P. Loosen, J. Coat. Technol. Res. 11, 3 (2014)

B. Cárcel, A. Serrano, J. Zambrano, A.C. Amigo cárcelc, Phys. Procedia 56, 284 (2014)

Z.T. Wang, X. Lin, Y.Q. Cao, F.C. Liu, W.D. Huang, Opt. Laser Technol. 99, 154 (2018)

X. Duan, S. Gao, Q. Dong, Y. Zhou, M. Xi, X. Xian, B. Wang, Surf. Coat. Technol. 291, 230 (2016)

Y.B. Cao, S.X. Zhi, Q. Gao, X.T. Tian, T. Geng, X. Guan, Mater. Charact. 119, 159 (2016)

N. Atta, M. Abd El Fatah, A. Galal, Int. J. Electrochem. Sci. 12, 1625 (2017)

V. Vijayaraghavan, S. Castagne, Measurement 115, 279 (2018)

J. Lin, J.J. Moore, B. Mishra, M. Pinkas, W.D. Sproul, Acta Mater. 58, 1554 (2010)

Acknowledgements

The author would like to acknowledge taiyuan science and technology project (170205) and Natural Science Foundation of China ((Nos. U1810112, 51604246) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Su, K., Bai, P. et al. Effect of TiBCN Content on Microstructure and Properties of Laser Cladding Ti/TiBCN Composite Coatings. Met. Mater. Int. 25, 1366–1377 (2019). https://doi.org/10.1007/s12540-019-00287-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00287-2