Abstract

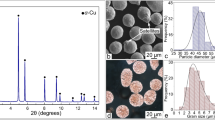

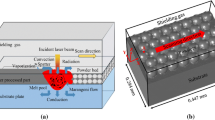

Porous 316L stainless steel deposits were fabricated by flame spraying semi-molten particles with different melting degrees and spray angles to understand the deposition behavior of semi-molten spray particles. The effects of spray angle relative on the deposition efficiency and deposit porosity were investigated. The morphology of individual splats deposited on flat surface at different angles was examined. The results show that the spray angle had a significant influence on the deposit porosity, pore structure, and deposition efficiency. The slipping of solid core in semi-molten spray particle was clearly observed when semi-molten particles impacted on the polished substrate with an inclined angle. A random model was proposed to simulate the process of particle deposition. It was found that after considering the effects of both solid particle slipping upon impact and particle melting degree, the porosity calculated by simulation with the model agreed well with the experimental observation.

Similar content being viewed by others

References

H. Yu, Z.X. Lin, and Y.H. Zhou, Simulation of Liquid Aluminum Infiltration in Fabrication of Porous Aluminum, Acta Aeronaut Astronaut Sin, 2000, 21(5), p 477-480 (in Chinese)

C. Jaeggi, V. Frauchiger, F. Eitel, M. Stiefel, H. Schmotzer, and S. Siegmann, The Effect of Surface Alloying of Ti Powder for Vacuum Plasma Spraying of Open Porous Titanium Coatings, Acta Mater., 2011, 59(2), p 717-725

J. Banhart, Manufacture, Characterisation and Application of Cellular Metals and Metal Foams, Prog. Mater. Sci., 2001, 46, p 559-632

R. Singh, P.D. Lee, J.R. Jones, G. Poologasundarampillai, T. Post, T.C. Lindley, and R.J. Dashwood, Hierarchically Structured Titanium Foam for Tissue Scaffold Applications, Acta Biomater., 2010, 6, p 4596-4604

M.M. Dewidar, K.A. Khalil, and J.K. Lim, Processing and Mechanical Properties of Porous 316L Stainless Steel for Biomedical Applications, Trans. Nonferr. Met. Soc. China, 2007, 17, p 468-473

A. Nakahira, F. Nishimura, S. Kato, and M. Iwata, Green Fabrication of Porous Ceramics Using an Aqueous Electrophoretic Deposition Process, J. Am. Ceram. Soc., 2003, 86, p 1230-1232

O. Volciuc, E. Monaico, M. Enachi, V.V. Ursaki, D. Pavlidis, V. Popa, and I.M. Tiginyanu, Morphology, Luminescence, and Electrical Resistance Response to H2 and CO Gas Exposure of Porous InP Membranes Prepared by Electrochemistry in a Neutral Electrolyte, Appl. Surf. Sci., 2010, 257, p 827-831

H.C. Gledhill, I.G. Turner, and C. Doyle, Direct Morphological Comparison of Vacuum Plasma Sprayed and Detonation Gun Sprayed Hydroxyapatite Coatings for Orthopaedic Applications, Biomaterials, 1999, 20, p 315-322

B. Chen, C.J. Li, G.J. Yang, J.T. Yao, H.B. Huo, and C.X. Li, Fabrication of Porous Molybdenum by Controlling Spray Particle State, J. Therm. Spray Technol., 2012, 21(5), p 1032-1045

G. Montavon, S. Sampath, C.C. Berndt, H. Herman, and C. Coddet, Effects of the Spray Angle on Splat Morphology During Thermal Spraying, Surf. Coat. Technol., 1997, 91, p 107-115

S.B. Mishra, K. Chandra, S. Prakash, and B. Venkataraman, Characterisation and Erosion Behaviour of a Plasma Sprayed Ni3Al Coating on a Fe-Based Superalloy, Mater. Lett., 2005, 59, p 3694-3698

H.O. Zhang, B.Y. Hu, and G.L. Wang, A Rapid Forming Method and Simulation on Controllable-Porosity Coating, Sci. China Ser. E, 2007, 50, p 786-796

C.W. Kang and H.W. Ng, Splat Morphology and Spreading Behavior due to Oblique Impact of Droplets onto Substrates in Plasma Spray Coating Process, Surf. Coat. Technol., 2006, 200, p 5462-5477

M. Pasandideh-Fard, S. Chandra, and J. Mostaghimi, A Three-Dimensional Model of Droplet Impact and Solidification, Int. J. Heat Mass Transfer, 2002, 45, p 2229-2242

V. Sobolev and J.M. Guilemany, Effect of Droplet Impact Angle on Flattening of Splat in Thermal Spraying, Mater. Lett., 1997, 32, p 197-201

C.J. Li and W.Y. Li, Deposition Characteristics of Titanium Coating in Cold Spraying, Surf. Coat. Technol., 2003, 167(2-3), p 278-283

K. Binder, J. Gottschalk, M. Kollenda, F. Gartner, and T. Klassen, Influence of Impact Angle and Gas Temperature on Mechanical Properties of Titanium Cold Spray Deposits, J. Therm. Spray Technol, 2010, 20, p 234-242

S. Deshpande, A. Kulkarni, S. Sampath, and H. Herman, Application of Image Analysis for Characterization of Porosity in Thermal Spray Coatings and Correlation with Small Angle Neutron Scattering, Surf. Coat. Technol., 2004, 187(1), p 6-16

D.B. Fowler, W. Riggs, and J.C. Russ, Inspecting Thermal Sprayed Coatings, Adv. Mater. Process., 1990, 11, p 41-52

K. Mailhot, F. Gitzhofer, and M.I. Boulos, Absolute Coating Porosity Measurement using Image Analysis, Proceedings of the 15th ITSC, Nice, France, Vol 1, 1998, p 917-922

Acknowledgments

The present project is financially supported by the Fund for the Doctoral Program of Higher Education of China (Grant No. 20120201130002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, JT., Ren, JQ., Huo, HB. et al. Deposition Behavior of Semi-Molten Spray Particles During Flame Spraying of Porous Metal Alloy. J Therm Spray Tech 23, 991–999 (2014). https://doi.org/10.1007/s11666-014-0119-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0119-9