Abstract

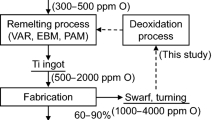

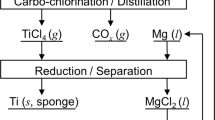

Deoxidation methods of titanium (Ti) scrap and Ti powder have become increasingly important in recent years. Some rare earth (RE) metals with strong deoxidizing capabilities, including Y, La, Ce, and Ho, are candidate agents for the development of a new deoxidation technology. In this study, a new method was developed to directly remove oxygen (O) from Ti using the Y/YOCl/YCl3 equilibrium. According to the calculation based on available thermodynamic data in the literature, the O concentration in β-Ti can be reduced to less than 10 ppm O at 1300 K (1027 °C) in the Y/YOCl/YCl3 equilibrium. To demonstrate the effectiveness of this method using the Y/YOCl/YCl3 equilibrium, the deoxidation limits of Ti samples using Y metal in YCl3 (l) or in YCl3-NaCl-KCl (l) at 1300 K (1027 °C) were experimentally investigated in this study. As a result, the O concentrations in the Ti samples were from 30 to 60 ppm O in YCl3 (l). This result revealed that Ti with extremely low O concentration can be reliably obtained using the RE/REOCl/RECl3 equilibrium for the first time. The establishment of this process will realize efficient recycling of Ti scrap and production of low O concentration Ti powder, which contribute to the large-scale use of Ti products.

Similar content being viewed by others

References

J. L. Murray, H. A. Wriedt: J. Phase Equilibria, 1987, vol. 8, pp. 148–65.

[2] T. B. Massalski, H. Okamoto, P. R. Subramanian and L. Kacprzak: Binary Alloy Phase Diagrams, American Society for Metals, OH, U.S., 1990.

P. Waldner and G. Eriksson: Calphad, 1999, vol. 23, pp. 189–218.

[4] O. Takeda and T. H. Okabe: JOM, 2019, vol. 71, pp. 1981–90.

[5] K. Ono and S. Miyazaki: J. Jpn. Inst. Met., 1953, vol. 82, pp. 87–91.

[6] K.Ono, T. H. Okabe, M. Ogawa, and R. Suzuki: J. Iron Steel Inst. Jpn., 1990, vol. 76, pp. 86–93 (in Japanese).

T. H. Okabe, R. O. Suzuki, T. Oishi, and K. Ono: Mater. Trans.(JIM), 1991, vol.32, pp. 485–88.

J. -M. Oh, B. -G. Lee, S.-W. Cho, S. -W. Lee, G.-S. Choi, and J. -W. Lim: Met. Mater. Int., 2011, vol. 17, pp. 733–736.

J. -M. Oh, B. -K. Lee, C. -Y. Suh, S. -W. Cho and J. -W. Lim: Powder Metall., 2012, vol. 55, pp. 402–04.

J.W. Lim, J.M. Oh, B.K. Lee, C.Y. Suh, S.W. Cho: US Patent No. 8,449,813, 2013.

J.W. Lim, J.M. Oh, B.K. Lee, C.Y. Suh, S.W. Cho: US Patent No. 8,449,646, 2013.

J.-M. Oh, H. Kwon, W. Kim, and J.-W. Lim: Thin Solid Films, 2014, vol. 551, pp. 98–101.

J.-M. Oh, C.-Y Suh, H. Kwon, J.-W. Lim and K.-M. Roh: J. Korean Inst. Resour Recycle, 2015, vol. 24, pp. 21–27. (in Korean)

J. -M. Oh, I. -H. Choi, C. -Y. Suh, H. Kwon, J. -W. Lim, and K. -M. Roh: Met. Mater. Int., 2016, vol. 22, pp. 488–92.

S.-J. Kim, J.-M. Oh, and J.-W. Lim: Met. Mater. Int., 2016, vol. 22, pp. 658–62.

C.-I. Hong, J.-M. Oh, J. Park, J.-M. Yoon, and J.-W. Lim: Adv. Powder Technol, 2018, vol. 29, pp. 1640–43.

J.-M. Oh, C.-I. Hong, J.-W. Lim: Adv. Powder Metall., 2019, vol. 30, pp. 1–5.

R.L. Fisher: US Patent No. 4,923,531, 1990.

R.L. Fisher: US Patent 5022935, 1991.

R.L. Fisher: US Patent 5211775A, 1993.

R.L. Fisher and S.R. Seagle: Proceedings of the 7th World Conference on Titanium, 1993, vol. 3, pp. 2265–72.

S.R. Seagle: Proceedings of the International Conference on Titanium Products and Applications, 1990, pp. 66–73.

T.H. Okabe, R. Suzuki, T. Oishi, and K. Ono: Tetsu-to-Hagane, 1991, vol. 77, pp. 93–99 (in Japanese).

T.H. Okabe, M. Nakamura, T. Ueki, T. Oishi, and K. Ono: Bulletin of the Japan Institute of Metals, 1992, vol. 31, pp. 315–317 (in Japanese).

T.H. Okabe, T. Oishi, and K. Ono: J. Alloys Compd., 1992, vol. 184, pp. 43–56.

T.H. Okabe, T. Oishi, and K. Ono: Metall. Mater. Trans. B, 1992, vol. 23, pp. 583–90.

S.-M. Han, Y.-S. Lee, J.-H. Park, G.-S. Choi, and D.-J. Min: Mater. Trans. (JIM), 2009, vol. 50, pp. 215–218.

Y. Xia, Z.Z. Fang, P. Sun, Y. Zhang, T. Zhang, and M. Free: J. Mater Sci., 2017, vol. 52, pp. 4120–28.

T.H. Okabe, M. Nakamura, T. Oishi and K. Ono: Metall. Mater. Trans. B, 1993, vol. 24, pp. 449–55.

M. Nakamura, T.H. Okabe, T. Oishi, and K. Ono: Proceedings of the International Symposium on Molten Salt Chemistry and Technology, Hawaii, U.S., 1993, pp. 529–40.

T. Oishi, T.H. Okabe, and K. Ono: J. Inst. Light Met., 1993, vol. 43, 1993, pp. 392–400.

T.H. Okabe, Y. Hamanaka, and Y. Taninouchi: Faraday Discuss., 2016, vol. 190, pp. 109–126.

Y. Taninouchi, Y. Hamanaka, and T.H. Okabe: Metall. Mater. Trans. B, 2016, vol.47, pp. 3394–3404.

Y. Taninouchi, Y. Hamanaka, and T.H. Okabe: Mater. Trans. (JIM), 2016, vol. 57, pp. 1309–18.

G.Z. Chen, D.J. Fray, and T.W. Farthing: Nature, 2000, vol. 407, pp. 361–64.

D. J. Fray: JOM, 2001, vol. 53, pp. 26–31.

G.Z. Chen, D.J. Fray, and T.W. Farthing: Metall. Mater. Trans. B, 2001, vol. 32, p.1041–52.

G.Z. Chen, D.J. Fray, and T.W. Farthing: US Patent, No 2004/0159559 A1, 2004.

K.S. Mohandas and D.J. Fray: Trans. Indian Inst. Met., 2004, vol. 57, p.579–592.

P.K. Tripathy, M. Gauthier, and D.J .Fray: Metall. Mater. Trans. B, 2007, vol. 38, pp. 893–900.

Metalysis Corporation: https://www.metalysis.com/technology/. Accessed on August 2019.

T.H. Okabe, T. Deura, T. Oishi, K. Ono, and D.R. Sadoway: J. Alloys Compd., 1996, vol. 237, pp. 150–154.

T.H. Okabe, T. Deura, T. Oishi, K. Ono, and D.R. Sadoway: Metall. Trans. B, 1996, vol.27, pp. 841–47.

T. H. Okabe, K. Hirota, E. Kasai, F. Saito, Y. Waseda, and K. T. Jacob: J. Alloys Compd., 1998, vol. 279, pp. 184–91.

T. H. Okabe, K. Hirota, Y. Waseda, and K. T. Jacob: Journal of MMIJ, 1998, vol.114, pp. 813–818.

C. Zheng, T. Ouchi, A. Iizuka, Y. Taninouchi, and T. H. Okabe: Mater. Trans. B, 2019, vol. 50, pp. 622–31.

C.Zheng, T. Ouchi, L. Kong, Y. Taninouchi, and T. H. Okabe: Metall Mater Trans B, 2019, vol. 50, pp. 1652–61.

L. Kong, T. Ouchi, and T. H. Okabe: Mater. Trans. (JIM), 2019, vol. 60, pp. 2059–2068.

L. Kong, T. Ouchi, and T.H. Okabe: J. Electrochem. Soc., 2019, vol. 166, pp. 429–437.

T. H. Okabe, C. Zheng, Y. Taninouchi: Metall. Mater. Trans. B, 2018, vol. 49, pp. 1056–66.

T. H. Okabe, Y. Taninouchi, C. Zheng: Metall. Mater. Trans. B, 2018, vol. 49, pp 3107–311.

Roskill Information Services: Rare Earths: Global Industry, Markets and Outlook to 2026, 16th Edition. Roskill Information Services, London, 2016.

O. Takeda, T. H. Okabe: Metall. Mater. Trans. E, 2014, vol. 1, pp 160–73.

I. Barin: Thermochemical Data of Pure Substances, 3rd ed., Wiley-VCH, Weinheim, Germany, 1995.

Y. B. Patrikeev, G. I. Novikov, and V. V. Badovskii, Russ. J. Phys. Chem., 1973, vol. 47, p. 284.

C. J. Rosa, Metall. Trans., 1970, vol. 1 (9), pp. 2517–22.

F. Swanson: Natl. Bur. Stand., vol. 2, 1953, p.41.

J. Welton and G. McCarthy: North Dakota State University, Fargo, NF, USA, 1989.

S. Katagiri, N. Ishikawa, and F. Marumo: Powder Diffr., vol. 8, 1993, p. 60.

H. E. Swanson, E. Tatge, and R. K. Fuyat: Standard X-ray Diffraction Powder Patterns, National Bureau of Standards, Washington, 1962, p. 51.

D.H. Templeton and G.F. Carter: J. Phys. Chem., 1954, vol. 58, pp. 940–944.

E. Sonneveld: Technisch Physische Diest, Delft, Netherlands.

M.A.C. Wevers, J.C. Schoen, M. Jansen, J. Solid State Chem., 1998, vol. 136, p.233.

Japan Oil, Gas and Metals National Corporation: http://mric.jogmec.go.jp/wp-content/uploads/2019/03/material_flow2018_Ti.pdf. Accessed on August 2019. (in Japanese).

Arum Publishing Company: Rare Metal News No. 2807, July 2018 issue, Tokyo, Japan, 2018. (in Japanese).

Acknowledgments

The authors are grateful to Dr. Lingxin Kong and Mr. Takara Tanaka at The University of Tokyo for their helpful suggestions and help in the experiments. This work was financially supported by the Japan Society for the Promotion of Science (JSPS) through a Grant-in-Aid for Scientific Research (s) (KAKENHI Grant Nos. 26220910, and 19H05623).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 13, 2019.

Rights and permissions

About this article

Cite this article

Iizuka, A., Ouchi, T. & Okabe, T.H. Ultimate Deoxidation Method of Titanium Utilizing Y/YOCl/YCl3 Equilibrium. Metall Mater Trans B 51, 433–442 (2020). https://doi.org/10.1007/s11663-019-01742-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01742-6