Abstract

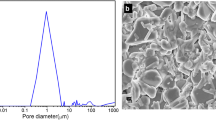

In this study, non-poisonous and eco-friendly raw chemicals were employed to synthesize a chabazite membrane by seed-induced secondary growth method. With an assistance of porous alumina ceramics support, the prepared membrane was utilized for excellent CO2/N2 separation. The results of structural and morphological characterization of the synthetic chabazite membrane signify that a dense and consistent membrane layer of chabazite was successfully formed on the surface of the alumina ceramic support. The single-component gas permeation experiment was carried out on the synthetic chabazite membrane, and the results showed that the calculated ideal CO2 and N2 separation coefficient reached 3.5. Whereas, the separation experiment of the mixed components showed the CO2 and N2 separation coefficient of 4.05 which might be due to the competition of diffusion between the mixed gas molecules and the selective adsorption characteristics of chabazite. At last, the separation stability experiments results show that the chabazite membrane prepared in this study owns excellent cycle stability and excellent separation performance. This demonstrates that chabazite membrane is an outstanding potential membrane for the separation of CO2 in industrial flue gas.

Similar content being viewed by others

References

Z.Y. Yeo, T.L. Chew, P.W. Zhu, A.R. Mohamed, S.-P. Chai, J. Nat. Gas Chem. 21, 282 (2012)

N.O. Chisholm, H.H. Funke, R.D. Noble, J.L. Falconer, J. Membr. Sci. 568, 17 (2018)

Z. Qiao, S. Zhao, M. Sheng, J. Wang, S. Wang, Z. Wang, C. Zhong, M.D. Guiver, Nat. Mater. 18, 163 (2019)

J.H. Lee, H.T. Kwon, S. Bae, J. Kim, J.H. Kim, Sep. Purif. Technol. 207, 427 (2018)

X. Gu, J. Dong, T.M. Nenoff, Ind. Amp Eng. Chem. Res. 44, 937 (2005)

J.H. Gong, C.H. Wang, Z.J. Bian, Y. Li, H.U. Jun, H.L. Liu, Acta Phys. Chim. Sin. 31, 1963 (2015)

I. Kammakakam, H.W. Yoon, S.Y. Nam, H. Bum Park, T.H. Kim, J. Membr. Sci. 487, 90 (2015)

S.T. Hwang, Korean J. Chem. Eng. 18, 775 (2001)

M. Vinoba, M. Bhagiyalakshmi, Y. Alqaheem, A.A. Alomair, M.S. Rana, Sep. Purif. Technol. 188, 431 (2017)

A.E. Amooghin, S. Mashhadikhan, H. Sanaeepur, A. Moghadassi, S. Ramakrishna, Prog. Mater. Sci. 102, 222 (2019)

A. Brunetti, F. Scura, G. Barbieri, E. Drioli, J. Membr. Sci. 359, 115 (2010)

H. Verweij, Curr. Opin. Chem. Eng. 1, 156 (2012)

J. Langwaldt, Sep. Sci. Technol. 43, 2166 (2008)

G.A. Nasser, O. Muraza, T. Nishitoba, Z. Malibari, T.K. Al-Shammari, T. Yokoi, Microporous Mesoporous Mater. 274, 277 (2019)

T. Du, X. Fang, Y. Wei, J. Shang, B. Zhang, L. Liu, Energy Fuels 31, 4301 (2017)

J. Shang, G. Li, R. Singh, Q. Gu, K.M. Nairn, T.J. Bastow, N. Medhekar, C.M. Doherty, A.J. Hill, J.Z. Liu, J. Am. Chem. Soc. 134, 19246 (2012)

C. Sun, D.J. Srivastava, P.J. Grandinetti, P.K. Dutta, Microporous Mesoporous Mater. 230, 208 (2016)

K. Kida, Y. Maeta, K. Yogo, J. Membr. Sci. 522, 363 (2017)

Z. Bohström, K.P. Lillerud, Microporous Mesoporous Mater. 271, 295 (2018)

C. Peng, Z. Liu, A. Horimoto, C. Anand, H. Yamada, K. Ohara, S. Sukenaga, M. Ando, H. Shibata, T. Takewaki, Microporous Mesoporous Mater. 255, 192 (2018)

B. Liu, Y. Zheng, N. Hu, T. Gui, Y. Li, F. Zhang, R. Zhou, X. Chen, H. Kita, Microporous Mesoporous Mater. 196, 270 (2014)

Y. Kunitake, T. Takata, Y. Yamasaki, N. Yamanaka, N. Tsunoji, Y. Takamitsu, M. Sadakane, T. Sano, Microporous Mesoporous Mater. 215, 58 (2015)

E. Jang, S. Hong, E. Kim, N. Choi, S.J. Cho, J. Choi, J. Membr. Sci. 549, 46 (2018)

K. Kida, Y. Maeta, K. Yogo, Sep. Purif. Technol. 197, 116 (2018)

L. Yu, A. Holmgren, M. Zhou, J. Hedlund, J. Mater. Chem. Mater. Energy Sustain. 6, 6847 (2018)

B. Liu, R. Zhou, K. Yogo, H. Kita, J. Membr. Sci. 573, 333 (2019)

J.P.G. Villaluenga, A. Tabe-Mohammadi, J. Polym. Eng. 23, 209–223 (2003)

N.A.A. Sani, W.J. Lau, A.F. Ismail, J. Polym. Eng. 34, 489 (2014)

B. D. Freeman, Novel Nanocomposite Membrane Structures for H2 Separations (University of Texas at Austin (US), 2005).

T. Burdyny, H. Struchtrup, Energy 35, 1884 (2010)

H. Gong, W. Liu, L. Liu, N. Goyal, T. Du, J. Taiwan Inst. Chem. Eng. 103, 160 (2019)

H. Aysan, S. Edebali, C. Ozdemir, M.C. Karakaya, N. Karakaya, Microporous Mesoporous Mater. 235, 78 (2016)

M. Lee, S. Hong, D. Kim, E. Kim, K. Lim, J.C. Jung, H. Richter, J.-H. Moon, N. Choi, J. Nam, Acs Appl. Mater. Interfaces 11, 3946 (2019)

W.M. Deen, M.P. Bohrer, N.B. Epstein, Aiche J. 27, 952–959 (1981)

A. Markovi, D. Stoltenberg, D. Enke, E.U. Schlünder, A. Seidel-Morgenstern, J. Membr. Sci. 336, 32 (2009)

S. Che, T. Du, S. Zhu, X. Fang, Y. Wang, J. Ceram. Soc. Jpn. 127, 606 (2019)

S. Che, L.Y. Liu, T. Du, X. Fang, Res. Chem. Intermed. 43, 1783 (2017)

J. Zhang, R. Singh, P.A. Webley, Microporous Mesoporous Mater. 111, 478 (2008)

Acknowledgements

This work was funded by the National Natural Science Foundation of China (No. 51904073, No.22078054), National Key Research and Development Project (No. 2019YFC1905200), the Natural Science Foundation of Liaoning Province (No. 2020-BS-053), the Postdoctoral Research Foundation of Northeastern University in China (No. 20190304) and the Fundamental Research Funds for the Central Universities (N182508027).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gong, H., Goyal, N., Liu, L. et al. Green synthesis strategy of chabazite membrane and its CO2/N2 separation performance. J Porous Mater 28, 1401–1410 (2021). https://doi.org/10.1007/s10934-021-01069-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-021-01069-1