Abstract

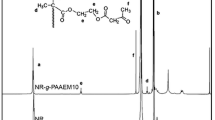

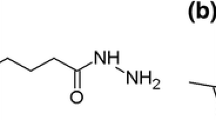

The concept of using glutaraldehyde (GTA) to crosslink natural rubber (NR) particles bearing diacetone acrylamide (DAAM) functional groups during film formation was investigated in the present work. The primary advantage of this curing system is that it is feasible under ambient conditions, which can lower operating costs of the curing process. Graft copolymers of NR and poly(diacetone acrylamide) prepared with 5 wt% of DAAM (NR–g–PDAAM5) were synthesized by seeded emulsion polymerization at 50 °C. Then, the tensile properties were measured for cast films formed from NR–g–PDAAM5 latex in the absence and presence of GTA. The results revealed increased tensile strength of the NR–g–PDAAM5 film, when GTA was added into the latex prior to film casting. The crosslinking of NR–g–PDAAM5 latex film by reaction with GTA, after film casting, was also investigated using attenuated total reflection Fourier transform infrared (ATR–FTIR) and dynamic mechanical thermal analysis (DMTA). ATR–FTIR analysis demonstrated that crosslinking reactions formed conjugated C=C double bonds between the active carbonyl groups of DAAM and GTA. The complementary use of DMTA also corroborated that crosslinking reactions took place involving the grafted PDAAM chains on the NR particles. This was evidenced by a clear shift towards higher temperatures of the tan δ peak, corresponding to the Tg of NR–g–PDAAM phase, when GTA was incorporated into the NR–g–PDAAM5 latex before film formation. Additionally, a noticeable increase in thermal stability of the NR–g–PDAAM5 film was also observed with added GTA. Hence, it can be concluded that GTA is an efficient room-temperature crosslinker for NR particles functionalized with DAAM. This curing system can also be considered an alternative, simple, and inexpensive method for curing NR latex compounds, as only one component (GTA) is required in the curing process.

Similar content being viewed by others

References

Feng J, Pham H, Macdonald P, Winnik MA, Geurts JM, Zirkzee H, van Es S, German AL(1998) J Coat Technol 70:57

Kessel N, Illsley DR, Keddie JL (2008) J Coat Technol Res 3:285

Foster AB, Lovell PA, Rabjohns MA (2009) Polymer 50:654

Tale NV, Jagtap RN (2010) Iran Polym J 19:801

Zhang X, Liu Y, Huang H, Li Y, Chen H (2012) J Appl Polym Sci 123:1822

Jones FN, Nichols ME, Pappas SP (2017) Organic coatings: science and technology, 4th edn. Wiley, Hoboken

Thongnuanchan B, Ninjan R, Kaesaman A, Nakason C (2015) Polym Bull 72:135

Olde Damink LHH, Dijkstra PJ, Van Luyn MJA, Van Wachem PB, Nieuwenhuis P, Feijen J (1995) J Mater Sci Mater Med 6:460

Farris S, Song J, Huang Q (2010) J Agric Food Chem 58:998

Kiernan JA (2000) Microsc Today 1:8

Gebben B, van den Berg HWA, Bargeman D, Smolders CA (1985) Polymer 26:1737

Dai S, Barbari TA (1999) J Membr Sci 156:67

Alemzadeh I, Vossoughi M (2002) Chem Eng Process 41:707

Figueiredo KCS, Alves TLM, Borges CP (2009) J Appl Polym Sci 111:3074

Kumbar SG, Soppimath KS, Aminabhavi TM (2003) J Appl Polym Sci 87:1525

Dmitriev I, Kuryndin I, Bobrova N, Smirnov M (2015) Mater Today Commun 4:93

Pye DJ (1960) Polymer composition and method. US Patent 2,960,486

Zweigle ML (1973) Removal of monomer from acrylamide polymers with sulfur dioxide. US Patent 3,780,006

Ellis B, Welding GN (1964) Rubber Chem Technol 37:563

Flory PJ, Rehener J (1943) J Chem Phys 11:521

Hagen R, Salmen L, Stenberg B (1996) J Polym Sci 34:1997

Gent AN, Kawahara S, Zhao J (1998) Rubber Chem Technol 71:668

Trabelsi S, Albouy P-A, Rault J (2002) Macromolecules 35:10054

Tosaka M, Kawakami D, Senoo K, Kohjiya S, Ikeda Y, Toki S, Hsiao BS (2006) Macromolecules 39:5100

Chenal J-M, Chazeau L, Guy L, Bomal Y, Gauthier C (2007) Polymer 48:1042

Huneau B (2011) Rubber Chem Technol 84:425

Migneault I, Dartiguenave C, Bertrand MJ, Waldron KC (2004) BioTechniques 37:790

Wang Y, Mo X, Sun XS, Wang D (2007) J Appl Polym Sci 104:130

Eng AH, Ong EL (2001) In: Bhowmick AK, S Howard (ed) Handbook of elastomers, 2nd edn. Marcel Dekker, Inc., New York, pp 29–60

Johns J, Nakason C, Thitithammawong A, Klinpituksa P (2012) Rubber Chem Technol 85:565

Honeycutt T, Flowery B (2005) Decreasing allergenicity of natural latex rubber prior to vulcanization. US Patent 20050277722 A1

Honeycutt T (2006) Decreasing allergenicity of natural latex rubber prior to vulcanization. US Patent 7056970 B2

Honeycutt T, William D, Matthew C, Russell C, Mark S (2007) Rubber World 237:32

Honeycutt T, Sharivker V, Sharivker S, Blinov V, Doyle W (2005) In international latex conference papers, Charlotte

Nakason C, Kaesaman A, Yimwan N (2003) J Appl Polym Sci 87:68

Smith MB (2015) Organic chemistry: an acid–base approach, 2nd edn. CRC Press, Boca Raton

Thongnuanchan B, Ninjan R, Kaesaman A, Nakason C (2015) J Polym Res 22:115

Ebewele RO (2000) Polymer science and technology. CRC Press LLC, Boca Raton

Hutchinson JM (1997) In: Haward RN, Young RJ (eds) The physics of glassy polymers, 2nd edn. Springer, London, pp 128–138

Phillips JC (1979) J Non-Cryst Solids 34:153

George S, Neelakantan NR, Varughese KT, Thomas S (1997) J Polym Sci B 35:2309

Burrows HD, Ellis HA, Utah SI (1981) Polymer 22:1740

Ozawa T (1965) Bull Chem Soc Jpn 38:1881

Park JW, Oh SC, Lee HP, Kim HT, Yoo KO (2000) Polym Degrad Stab 67:535

Ceamanos J, Mastral JF, Millera A, Aldea ME (2002) J Anal Appl Pyrol 65:93

Popescu C (1996), Thermochim Acta 285:309

Kim W, Kim SD, Lee SB, Hong IN (2000) J Ind Eng Chem 6:348

Acknowledgements

This work was supported by the Research Fund of Prince of Songkla University, SAT581267S. The authors would like to thank the Research and Development Office (RDO) and Assoc. Prof. Seppo Karrila for editing this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thongnuanchan, B., Ninjan, R., Kalkornsurapranee, E. et al. Glutaraldehyde as Ambient Temperature Crosslinking Agent of Latex Films from Natural Rubber Grafted with Poly(diacetone acrylamide). J Polym Environ 26, 3069–3085 (2018). https://doi.org/10.1007/s10924-018-1193-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1193-8