Abstract

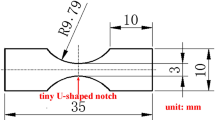

Many metal materials possess the transition from strain localization to fracture, the so-called post-necking behavior, during large deformation under tensile load. It is crucial to understand and characterize the transition for the application of these materials. In this paper, the stress state dependence of the transition from strain localization to fracture of Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy is characterized and analyzed by carrying out experiments and phase-field modeling. Firstly, tensile tests for smooth and notched round bars were conducted, in which the notched specimens have different notch radius. It was observed in the tests that the sharper the notch, the shorter the transition process, which can be explained as that high stress triaxiality would shorten the transition process. To further quantify the effects of stress triaxiality in the transition process, the phase-field fracture model involving the nucleation, growth and coalescence of micro-voids is developed to simulate and characterize the damage evolution observed in experiments. The simulations show that as the stress triaxiality increases, the material undergoes less plastic deformation, whether in the initiation of strain localization or the transition process. More interestingly, it is found that there exists a critical value of stress triaxiality, which can be considered the characteristic point of brittle-ductile transition. Above this point, the material has almost no plastic deformation before localization, and brittle fracture occurs directly. This work is meaningful for evaluating the safety of metal structures under complex loads.

Similar content being viewed by others

References

Aldakheel F, Wriggers P, Miehe C (2018) A modified Gurson-type plasticity model at finite strains: formulation, numerical analysis and phase-field coupling. Comput Mech 62:815–833

Alexandrov SE, Goldstein RV (1998) Distributions of stress and plastic strain in notched tensile bars. Int J Fract 91:1–11

Ambati M, Gerasimov T, De Lorenzis L (2015) Phase-field modeling of ductile fracture. Comput Mech 55:1017–1040

Anvari M, Liu J, Thaulow C (2007) Dynamic ductile fracture in aluminum round bars: experiments and simulations. Int J Fract 143:317–332

Areias P, Rabczuk T, Msekh MA (2016) Phase-field analysis of finite-strain plates and shells including element subdivision. Comput Methods Appl Mech Eng 312:322–350

Bai Y, Wierzbicki T (2008) A new model of metal plasticity and fracture with pressure and Lode dependence. Int J Plast 24:1071–1096

Bai Y, Wierzbicki T (2010) Application of extended Mohr-Coulomb criterion to ductile fracture. Int J Fract 161:1–20

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46:81–98

Becker R, Needleman A, Richmond O, Tvergaard V (1988) Void growth and failure in notched vars. J Mech Phys Solids 36:317–351

Benzerga A (2002) Micromechanics of coalescence in ductile fracture. J Mech Phys Solids 50:1331–1362

Benzerga A, Leblond JB, Needleman A, Tvergaard V (2016) Ductile failure modeling. Int J Fract 201:29–80

Borden MJ, Hughes TJR, Landis CM, Anvari A, Lee IJ (2016) A phase-field formulation for fracture in ductile materials: finite deformation balance law derivation, plastic degradation, and stress triaxiality effects. Comput Methods Appl Mech Eng 312:130–166

Bourdin B (2007) Numerical implementation of the variational formulation for quasi-static brittle fracture. Interfaces Free Bound 9:411–430

Bourdin B, Francfort GA, Marigo J-J (2000) Numerical experiments in revisited brittle fracture. J Mech Phys Solids 48:797–826

Brünig M, Chyra O, Albrecht D, Driemeier L, Alves M (2008) A ductile damage criterion at various stress triaxialities. Int J Plast 24:1731–1755

Brünig M, Gerke S, Hagenbrock V (2013) Micro-mechanical studies on the effect of the stress triaxiality and the Lode parameter on ductile damage. Int J Plast 50:49–65

Chu D, Li X, Liu Z (2017) Study the dynamic crack path in brittle material under thermal shock loading by phase field modeling. Int J Fract 208:115–130

Chu D, Li X, Liu Z, Cheng J, Wang T, Li Z, Zhuang Z (2019) A unified phase field damage model for modeling the brittle-ductile dynamic failure mode transition in metals. Eng Fract Mech 212:197–209

Coppieters S, Cooreman S, Sol H, Houtte PV, Debruyne D (2011) Identification of the post-necking hardening behaviour of sheet metal by comparison of the internal and external work in the necking zone. J Mater Process Technol 211:545–552

Driemeier L, Moura RT, Machado IF, Alves M (2015) A bifailure specimen for accessing failure criteria performance. Int J Plast 71:62–86

Farren WS, Taylor GI (1925) The heat developed during plastic extension of metals. Proc Roy Soc Lond A 107:422–451

Goswami S, Anitescu G, Chakraborty S, Rabczuk T (2020) Transfer learning enhanced physics informed neural network for phase-field modeling of fracture. J Theor Appl Mech 106:102447

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: Part I-yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99:2–15

Hakim V, Karma A (2009) Laws of crack motion and phase-field models of fracture. J Mech Phys Solids 57:342–368

Hodowany J, Ravichandran G, Rosakis AJ, Rosakis P (2000) Partition of plastic work into heat and stored energy in metals. Exp Mech 40:113–123

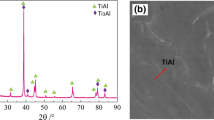

Huang LJ, Geng L, Li AB, Wang GS, Cui XP (2008) Effects of hot compression and heat treatment on the microstructure and tensile property of Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy. Mater Sci Eng A 489:330–336

Ji Z, Chen Y, Qiang Y, Shen C, Li H (2018) Effect of deformation of constituent phases on mechanical properties of Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. Mater Sci Eng A 723:29–37

Kim JH, Serpantié A, Barlat F, Pierron F, Lee MG (2013) Characterization of the post-necking strain hardening behavior using the virtual fields method. Int J Solids Struct 50:3829–3842

Knysh P, Korkolis YP (2017) Identification of the post-necking hardening response of rate- and temperature-dependent metals. Int J Solids Struct 115–116:149–160

Koplik J, Needleman (1988) Void growth and coalescence in Porous plastic solids. Int J Solids Struct 24:835–853

Li Y, Wierzbicki T (2010) Prediction of plane strain fracture of AHSS sheets with post-initiation softening. Int J Solids Struct 47:2316–2327

Lu S, Bao R, Wang K, Liu D, Wu Y, Fei B (2017) Fatigue crack growth behavior in laser melting deposited Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy. Mater Sci Eng A 690:378–386

Macdougall D (2000) Determination of the plastic work converted to heat using radiometry. Exp Mech 40:298–306

Mason JJ, Rosakis AJ, Ravichandran G (1994) On the strain and strain rate dependence of the faction of plastic work converted to heat: an experimental study using high speed infrared dectoctora and the Kolsky bar. Mech Mater 17:135–145

McAuliffe C, Waisman H (2015) A unified model for metal failure capturing shear banding and fracture. Int J Plast 65:131–151

McAuliffe C, Waisman H (2016) A coupled phase field shear band model for ductile-brittle transition in notched plate impacts. Comput Methods Appl Mech Eng 305:173–195

Miehe C, Hofacker M, Welschinger F (2010a) A phase field model for rate-independent crack propagation: robust algorithmic implementation based on operator splits. Comput Methods Appl Mech Eng 199:2765–2778

Miehe C, Welschinger F, Hofacker M (2010b) Thermodynamically consistent phase-field models of fracture: variational principles and multi-field FE implementations. Int J Numer Methods Eng 83:1273–1311

Miehe C, Hofacker M, Schanzel LM, Aldakheel F (2015) Phase field modeling of fracture in mulTi–physics problems. Part II. Coupled brittle-to-ductile failure criteria and crack propagation in thermos-elastic-plastic solids. Comput Methods Appl Mech Eng 294:486–522

Miehe C, Aldakheel F, Raina A (2016) Phase field modeling of ductile fracture at finite strains: A variational gradient-extended plasticity-damage theory. Int J Plast 84:1–32

Mirone G, Corallo D (2010) A local viewpoint for evaluating the influence of stress triaxiality and Lode angle on ductile failure and hardening. Int J Plast 26:348–371

Moftakhar A, Buczynski A, Glinka G (1995) Calculation of elasto-plastic strains and stresses in notches under multiaxial loading. Int J Fract 70:357–373

Needleman A, Tvergaard V (1984) An analysis of ductile rupture in notched bars. J Mech Phys Solids 32:461–490

Pardoen T, Hutchinson JW (2000) An extended model for void growth and coalescence. J Mech Phys Solids 48:2467–2512

Pineau A, Benzerga A, Pardoen T (2016) Failure of metals I: Brittle and ductile fracture. Acta Mater 107:424–483

Rabczuk T, Belytschko T (2004) Cracking particles: a simplified meshfree method for arbitrary evolving cracks. Int J Numer Methods Eng 61:2316–2343

Ren H, Zhuang X, Cai Y, Rabczuk T (2016) DuAl–horizon peridynamics. Int J Numer Methods Eng 108:1451–1476

Ren H, Zhuang X, Anitescu C, Rabczuk T (2019) An explicit phase field method for brittle dynamic fracture. Comput Struct 217:45–56

Rosa GL, Mirone G, Risitano A (2003) Postnecking elastoplastic characterization: degree of approximation in the Bridgman method and properties of the flow-stress/true-stress ratio. Met Mater Trans A 34A:615–624

Roth CC, Mohr D (2018) Determing the strain to fracture for simple shear for a wide range of sheet metals. Int J Mech Sci 149:224–240

Spencer K, Corbin SF, Lloyd DJ (2002) The influence of iron content on the plane strain fracture behavior of AA 5754 Al–Mg sheet alloys. Mater Sci Eng A 325:394–404

Taylor GI, Quinney H (1937) The latent heat remaining in a metal after cold working. Proc Roy Soc Lond A 163:157–181

Tekoǧlu C, Hutchinson JW, Pardoen T (2015) On localization and void coalescence as a precursor to ductile fracture. Phil Trans R Soc A 373:20140121

Wang L, Tong W (2015) Identification of post-necking strain hardening behavior of thin sheet metals from image-based surface strain data in uniaxial tension tests. Int J Solids Struct 75–76:12–31

Wang T, Liu Z, Cui Y, Ye X, Liu X, Tian R, Zhuang Z (2020a) A thermo–elastic-plastic phase-field model for simulating the evolution and transition of adiabatic shear band. Part I. Theory and model calibration. Eng Fract Mech 232:107028

Wang T, Ye X, Liu Z, Liu X, Chu D, Zhuang Z (2020b) A phase-field model of therMo–elastic coupled brittle fracture with explicit time integration. Comput Mech 65:1305–1321

Xue Z, Pontin MG, Zok FW, Hutchinson JW (2010) Calibration procedures for a computational model of ductile fracture. Eng Fract Mech 77:492–509

Zhang B, Lei LM, Jiang XL, Song ZM, Huang X, Zhang GP (2013) On temperature and strain rate dependent strain localization behavior in Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy. J Mater Sci Technol 29:273–278

Zhu Y, Liu D, Tian X, Tang H, Wang H (2014) Characterization of microstructure and mechanical properties of laser melting deposited Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. Mater Des 56:445–453

Zong X, Li Z, Li J, Cheng X, Chen R, Tan CW, Wang HM (2019) High strain rate response of Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy fabricated by laser additive manufacturing. J Alloys Compd 781:47–55

Acknowledgements

This work is supported by the National Natural Science Foundation of China, under Grant Nos. 12002181, 11921002, 11972205 and 11722218, Beijing Municipal Science & Technology Commission (Z191100002019013) and the Open Research Fund from Beijing Advanced Innovation Center for Big Data-Based Precision Medicine, Beijing Tongren Hospital, Beihang University & Capital Medical University (BHTR-KFJJ-202004). The authors also would like to thank the Ministry of Industry and Information Technology of China under Grant No. MJ-2017-F-20 for the financial support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Wang, K., Wang, T. et al. Study of the transition from strain localization to fracture of Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy by experiments and phase-field modeling. Int J Fract 231, 95–108 (2021). https://doi.org/10.1007/s10704-021-00567-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-021-00567-2