Abstract

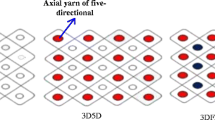

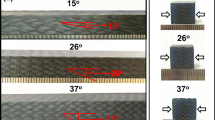

Numerical studied on T-joints with three-dimensional four directional (3D4D) braided composite fillers was presented in this article. Compared with conventional unidirectional prepreg fillers, the 3D braided composite fillers have excellent ability to prevent crack from penetrating trigone fillers, which constantly occurred in the conventional fillers. Meanwhile, the 3D braided composite fillers had higher fiber volume fraction and eliminated the fiber folding problem in unidirectional prepreg fillers. The braiding technology and mechanical performance of 3D4D braided fillers were studied. The numerical model of carbon fiber T-joints with 3D4D braided composite fillers was built by finite element analysis software. The damage formation, extension and failing process of T-joints with 3D4D braided fillers under tensile load were investigated. Further investigation was extended to the effect of 3D4D braided fillers with different braiding angles on mechanical behavior of the T-joints. The study results revealed that the filling area was the weakest part of the T-joints where the damage first appeared and the crack then rapidly spread to the glue film around the filling area and the interface between over-laminate and soleplate. The 3D4D braided fillers were undamaged and the braiding angle change induced a little effect on the bearing capacity of T-joints.

Similar content being viewed by others

References

Kumari S., Sinha P.K.: Finite Element Analysis of Composite Wing T-Joints. J Reinf Plastics Compos (USA). 21(17), 1561–1585 (2002)

Khalili S.M.R., Ghaznavi A. Behavior and failure modes of sandwich T-Joint using cohesive Zone material model and contact elements. Appl Compos Mater. 20(1), 41–54 (2013)

Vijayaraju K., Mangalgiri P.D., Dattaguru B.: Experimental Study of Failure and Failure Progression in T-Stiffened Skins. Compos Struct. 64(2), 227–234 (2004)

Libin Zhao, Tianliang Qin, Yuli Chen, ,Jianyu Zhang. Three-dimensional progressive damage models for cohesively bonded composite π joint. J Compos Mater. 48(6), 707–721(2014)

Dharmawan F., Thomson R.S., Li H.: Geometry and damage effects in a composite marine T-joint [J]. Compos Struct. 66, 181–187 (2004)

Cui H., Li Y.L., Liu Y.Y., et al.: Numerical simulation of composites joints failure based on cohesive zone model. Fuhe Cailiao Xuebao/acta Materiae Compositae Sinica. 27(2), 161–168 (2010)

Cheng X., Xiong J.J., Peng B., et al.: Mechanical properties of RTM-made composite cross-joints. Chin J Aeronaut. 22(2), 211–217 (2009)

Jinrui M.A., Feng H.U.A.N.G., Long Z.H.A.O., et al.: Effect of fillers on tensile pull-off properties of the RTM composited T-joint [J]. JChangchun University Technol. 36(4), 451–455 (2015)

Li H.C.H., Dharmawan F., Herszberg I., et al.: Fracture behaviour of composite maritime T-joints. Commun Strateg. 75(1–4), 339–350 (2006)

Sheng Y., Xiong K., Bian K., et al.: Fracture behavior of carbon fiber T-joints under tensile load. Fuhe Cailiao Xuebao/acta Materiae Compositae Sinica. 30(6), 185–190 (2013)

Falzon B.G., Apruzzese P.: Numerical analysis of intralaminar failure mechanisms in composite structures. Part II: Applications Compos Struct. 93(2), 1047–1053 (2011)

De Borst R.: Numerical aspects of cohesive-zone models. Eng Fract Mech. 70(14), 1743–1757 (2003)

Shanmugam V., Penmetsa R., Tuegel E., et al.: Stochastic modeling of delamination growth in unidirectional composite DCB specimens using cohesive zone models. Compos Struct. 102, 38–60 (2013)

Vandellos T., Huchette C., Carrere R.: Proposition of a framework for the development of a cohesive zone model adapted to carbon-fiber reinforced plastic laminated composites. Compos Struct. 105, 199–206 (2013)

Cheng P.H., Chai Y.N.: Cohesive zone model for failure analysis of integrated composite structures. J Nanjing Univ Aeronaut Astronaut. 40(4), 442–446 (2008)

Borg R., Nilsson L., Simonsson K., Simulating D.C.B.: ENF and MMB experiments using shell elements and a cohesive zone model. Combust Sci Technol. 64(2), 269–278 (2004)

Moroni F., Pirondi A.: Cohesive zone model simulation of fatigue debonding along interfaces. Procedia Eng. 10, 1829–1834 (2011)

Haj-Ali R., El-Hajjar R., Muliana A.: Cohesive fracture modeling of crack growth in thick-section composites. Eng Fract Mech. 73(15), 2192–2209 (2006)

Lorentz E.: A mixed interface finite element for cohesive zone models. Comput Methods Appl Mech Eng. 198(2), 302–317 (2008)

Giulio A.: On the influence of the shape of the interface law on the application of cohesive-zone models [J]. Compos Sci Technol. 66(6), 723–730 (2006)

Kou J.F., Xu F., Guo J.P., et al.: Damage laws of cohesive zone model and selection of the parameters. J Mech Strength. 33(5), 714–718 (2011)

Qusen Z.: Evaluation of the toughness of QY8911 Bismaleimde [J]. Acta Aeronautica Et Astronautica Sinica. 112(12), 583–588 (1991)

Chamis C.C.: Mechanics of Composites Materials: Past, Present and Future [J]. J Compos Technol Res. 11(1), 3–14 (1989)

Zvi. Hashin, Failure Criteria for Unidirectional Fiber Composites. J Appl Mech. 47(2), 329–334 (1980)

Naaman A.E., Argon A.S., Moavenzadeh F.: Cem Concr Res. 3(4), 397 (1973)

Guo-dong F., Jun L., Bao-lai W.: Progressive damage and nonlinear analysis of 3D four-directional braided composites under unidirectional tension. Compos Struct. 89(1), 126 (2009)

Bažant Z.P., Oh B.H.: Crack band theory for fracture of concrete. Matériaux et Construction. 16(3), 155–177 (1983)

Cordebois J., Sidoroff F. Damage induced elastic anisotropy [M]. Mechanical behavior of anisotropic solid/ comportment méchanique des solides anisotropes. Springer Netherlands, 1982: 761–774

Acknowledgments

The authors acknowledge the support of Beijing 3DBraiding Co. Ltd.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Xk., Liu, Zg., Hu, L. et al. Numerical Investigation of T-joints with 3D Four Directional Braided Composite Fillers Under Tensile Loading. Appl Compos Mater 24, 171–191 (2017). https://doi.org/10.1007/s10443-016-9520-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-016-9520-5