Abstract

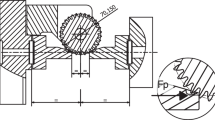

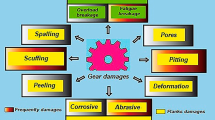

Gear tooth bending fatigue failures are instantaneously catastrophic to gear drive power transmission systems. For this reason, gear designers must understand the limits of their design with respect to the desired application and service time. Fatigue testing on gear specimens has been preferred metric on which to base future designs. Single Tooth Bending test (STB) or a Rotating Gear (RG) test methodologies have been used for this purpose. STB type tests generally form the large majority of gear fatigue testing due to cost and availability but does not fully simulate the actual operating conditions of rotating gears in service. As RG evaluations are costly and time-consuming, it is desirable to quantify how a stress-life (SN) relationship regressed through STB testing compares to that produced in RG testing. In this study, both STB and RG test methodologies are employed to test the same specimen design. Matrices of fatigue tests are executed and statistical regression techniques are used to estimate bending fatigue lives as a function of stress for both sets of data. The resultant SN curves are compared to determine any differences in allowable stress. Techniques are then employed using single set data (STBF or RG individually) to demonstrate the calculation of correlation coefficients, which can approximate the total difference determined between the two data sets.

Zusammenfassung

Ermüdungsfehler der Zahnzahnbiegung sind augenblicklich katastrophal für Getriebeantriebssysteme. Ermüdungsprüfungen an Verzahnungsproben wurden für zukünftige Konstruktionen bevorzugt. STB-Baumusterprüfungen bilden in der Regel aufgrund der Kosten und der Verfügbarkeit die überwiegende Mehrheit der Getriebeermüdungsprüfungen, simulieren aber nicht vollständig die tatsächlichen Betriebsbedingungen rotierender Zahnräder im Betrieb. In dieser Studie werden sowohl STB- als auch RG-Testmethoden verwendet, um dasselbe Probendesign zu testen. Die resultierenden SN-Kurven werden verglichen, um eventuelle Unterschiede in der zulässigen Spannung zu bestimmen. Techniken werden dann unter Verwendung einzelner gesetzter Daten (STBF oder RG einzeln) verwendet, um die Berechnung der Korrelationskoeffizienten zu demonstrieren, die die Gesamtdifferenz näherungsweise bestimmen können, die zwischen den zwei Datensätzen bestimmt wird.

Similar content being viewed by others

Abbreviations

- B 50 :

-

50% failure rate

- f :

-

fatigue test frequency

- f s :

-

number of surface initiated failures

- f s s :

-

number of subsurface initiated failures

- F :

-

STBF test applied force

- K d :

-

dynamic factor

- K I :

-

initiation location factor

- K S :

-

statistical factor

- K R S :

-

total RG to STB factor

- K F :

-

loading factor

- K R :

-

stress factor

- N :

-

number of cycle in a test

- N f :

-

number of cycles to failure

- \(N_{if}^{s}\) :

-

number of cycles to failure for a surface initiated specimen

- \(N_{if}^{ss}\) :

-

number of cycle to failure for a subsurface initiated specimen

- p :

-

failure percentile

- q R G :

-

failure percentile of teeth on a RG specimen

- r f :

-

ratio of surface initiated to total number of failures

- R :

-

fatigue test stress ratio

- α 1 :

-

regressed intercept constant

- α 2 :

-

regressed slope constant

- β 1 :

-

regressed variance constant

- γ :

-

regressed fatigue strength constant

- σa :

-

stress amplitude

- σm :

-

stress mean

- σult :

-

ultimate tensile stress

- \(\sigma _{\mathrm{fat}-RG}\) :

-

fatigue strength from RG test

- \(\sigma _{\mathrm{fat}-\mathrm{STB}}\) :

-

fatigue strength from STBF test

- \(\overline{\sigma }_{g}^{f=0}\) :

-

measured gage stress at 0 Hz

- \(\overline{\sigma }_{g}^{f=40}\) :

-

measured gage stress at 40 Hz

- \(\overline{\sigma }_{\max }\) :

-

normalized maximum gear tooth root bending stress

- \(\overline{\sigma }_{RG}^{\left(p\right)}\left(N_{f}\right)\) :

-

RG SN curve at specified failure percentile

- \(\overline{\sigma }_{\mathrm{STB}}^{\left(p\right)}\left(N_{f}\right)\) :

-

STB SN curve at specified failure percentile

References

Yamanaka M, Matsushima Y, Miwa S, Nartta Y, Inoue K, Kawasaki Y (2010) Comparison of bending fatigue strength among spur gears manufactured by various methods: (influence of manufacturing method on bending strength). J Adv Mech Des Syst Manuf 4(2):480–491

Winkler K, Schurer S, Tobie T, Stahl K (2019) Investigations on the tooth root bending strength and the fatigue fracture characteristics of case-carburized and shot-peened gears of different sizes. Proc Inst Mech Eng Part C J Mech Eng Sci 233(21–22):7338–7349

Oda S, Shimatomi Y (1980) Study on bending fatigue strength of helical gears (1st report, effect of helix angle on bending fatigue strength). Bull JSME 23(177):453–460

Oda S, Shimatomi Y (1980) Study on bending fatigue strength of helical gears (2nd report, bending fatigue strength of carehardened helical gears). Bull JSME 23(177):461–468

Medlin D, Krauss G, Matlock DK, Burris K, Slane M (1995) Comparison of single gear tooth and cantilever beam bending fatigue testing of carburized steel. SAE Pap, vol 950212

Mcpherson DR, Rao SB (2008) Methodology for translating single-tooth bending fatigue data to be comparable to running gear data. Gear Technology: 42–51

Krantz T, Tufts B (2008) Pitting and bending fatigue evaluations of a new case-carburized gear steel. Gear Technol:863–869. https://doi.org/10.1115/DETC2007-34090

Kodeeswaran M, Verma A, Suresh R, Senthilvelan S (2016) Bi-directional and uni-directional bending fatigue performance of unreinforced and carbon fiber reinforced polyamide 66 spur gears. Int J Precis Eng Manuf 17(8):1025–1033

Hohn B‑R, Oster P, Tobie T (2003) Systematic investigations on the influence of case depth on the pitting and bending strength of case carburized gears. In: DETC2003/PTG, Chicago, pp 111–119

Handschuh RF, Krantz T, Lerch BA, Burke CS (2007) Investigation of low-cycle bending fatigue of AISI 9310 steel spur gears. NASA TM, vol 214914

Haberer C, Leitner H, Eichlseder W, Dietrich A (2009) Fatigue life behavior of a hypoid gear tooth root taking the influences of orbital forging into account. In: SAE World Congress and Exhibition, SAE International

Gasparini G, Mariani U, Gorla C, Filippini M, Rosa F (2009) Bending fatigue tests of helicopter case carburized gears: influence of material, design and manufacturing parameters. Gear Technol 26(8):68–76

Wheitner J, Houser DR (1994) Investigation of the effects of manufacturing variations and materials on fatigue crack detection methods in gear teeth. NASA CR, vol 195093

Dobler F, Tobie T, Stahl K (2015) Influence of low temperatures on material properties and tooth root bending strength of case-hardened gears. Proc. ASME Des. Eng. Tech. Conf., vol 10

Dobler F, Tobie T, Stahl K, Nadolski D, Steinbacher M, Hoffmann F (2016) Influence of hardening pattern, base material and residual stress condition on the tooth root bending strength of induction hardened gears. In: Proceedings of the International Conference on Power Transmissions, pp 287–294

Dobler A, Hergesell M, Tobie T, Stahl K (2016) Increased tooth bending strength and pitting load capacity of fine-module gears. Gear Technol 33(7):48–53

Conrado E, Gorla C, Davoli P, Boniardi M (2017) A comparison of bending fatigue strength of carburized and nitrided gears for industrial applications. Eng Fail Anal 78:41–54

Blais P, Toubal L (2020) Single-gear-tooth bending fatigue of HDPE reinforced with short natural fiber. Int J Fatigue 141:105857

Benedetti M, Fontanari V, Höhn BR, Oster P, Tobie T (2002) Influence of shot peening on bending tooth fatigue limit of case hardened gears. Int J Fatigue 24(11):1127–1136

Wagner M, Isaacson A, Knox K, Hylton T, Wagner M, Isaacson A, Knox K, Hylton T (2020) Single tooth bending fatigue testing at any R ratio. In: AGMA Fall Technical Meeting 20FTM09, pp 1–14

Stringer DB, Dykas BD, Laberge KE, Zakrajsek AJ, Handschuh RF (2011) A new high-speed, high-cycle, gear-tooth bending fatigue test capability. NASA TM, vol 217039

Shen T, Krantz T, Sebastian J (2011) Advanced gear alloys for ultra high strength applications. NASA TM, vol 217121

Seabrook JB, Dudley DW (1964) Results of a fifteen-year program of flexural fatigue testing of gear teeth. J Eng Ind 86(3):221–237

Savaria V, Bridier F, Bocher P (2016) Predicting the effects of material properties gradient and residual stresses on the bending fatigue strength of induction hardened aeronautical gears. Int J Fatigue 85:70–84

Sanders A, Houser DR, Kahraman A, Harianto J, Shon S (2011) An experimental investigation of the effect of tooth asymmetry and tooth root shape on root stresses and single tooth bending faituge life of gear teeth. In: ASME International Power Transmission and Gearing Conference, Washington D.C.

SAE International Surface Vehicle Recommended Practice (1997) Single tooth gear bending fatigue test. SAE Stand, vol J1619

Rao SB, Mcpherson DR (2003) Experimental characterization of bending fatigue strength in gear teeth. Gear Technol 20:25–32

Phelan PE, Sell DJ, Dowling WE (1996) Bending fatigue behavior of carburized gear steels: planetary gear test development and evaluation. SAE Pap, vol 960978

Hong IJ, Kahraman A, Anderson N (2020) A rotating gear test methodology for evaluation of high-cycle tooth bending fatigue lives under fully reversed and fully released loading conditions. Int J Fatigue 133:105432

Hong IJ, Kahraman A, Anderson N (2021) An experimental evaluation of high-cycle gear tooth bending fatigue lives under fully reversed and fully released loading conditions with application to planetary gear sets. J Mech Des 143(2):1–9

Hatano A, Namiki K (1992) Application of hard shot peening to automotive transmission gears. SAE Pap, vol 938179

Hasl C, Illenberger C, Oster P, Tobie T, Stahl K (2018) Potential of oil-lubricated cylindrical plastic gears. J Adv Mech Des Syst Manuf 12(1):1–9

Hong IJ, Kahraman A, Anderson N (2020) An experimental evaluation of high-cycle gear tooth bending fatigue lives under fully reversed and fully released loading conditions with application to planetary gear sets. J Mech Des 143(2). https://doi.org/10.1115/1.4047687

Selines RJ (1972) Effect of cyclic stress wave form on corrosion fatigue crack propagation in Al-Zn-Mg alloys. Met Trans 3(9):2525–2531

Menan F, Henaff G (2009) Influence of frequency and exposure to a saline solution on the corrosion fatigue crack growth behavior of the aluminum alloy 2024. Int J Fatigue 31(11–12):1684–1695

Müller G (1873) Zulässige Inanspruchnahme Des Schmiedeeisens Bei Brückenkonstruktionen. Z Österr Ing Archit 25:197–202

Sendeckyj GP (2001) Constant life diagrams—A historical review. Int J Fatigue 23(4):347–353

Novovic D, Dewes RC, Aspinwall DK, Voice W, Bowen P (2004) The effect of machined topography and integrity on fatigue life. Int J Mach Tools Manuf 44(2–3):125–134

Murakami Y (2002) Metal fatigue: effects of small defects and nonmetallic inclusions

Nakajima M, Tokaji K, Itoga H, Ko HN (2003) Morphology of step-wise S‑N curves depending on work-hardened layer and humidity in a high-strength steel. Fatigue Fract Eng Mater Struct 26(12):1113–1118

Stahl K (1999) Statistische Methoden Zur Beurteilung von Bauteillebensdauer Und Zuverlässigkeit Und Ihre Beispielhafte Anwendung Auf Zahnräder. FVA-Forschungsvorhaben, vol 304. Forschungsvereinigung Antriebstechnik, Frankfurt

Rettig H (1987) Ermittlung von Zahnfußfestigkeitskennwerten Auf Verspannungsprüfständen Und Pulsatoren-Vergleich Der Prüfverfahren Und Der Gewonnenen Kennwerte. Antriebstechnik 26:51–55

Pyttel B, Schwerdt D, Berger C (2011) Very high cycle fatigue—Is there a fatigue limit? Int J Fatigue 33(1):49–58

The Gear and Power Transmission (2021) Research Laboratory Windows-LDP, load distribution program. The Ohio State University, Columbus

Pascual FG, Meeker WQ (1997) Analysis of fatigue data with runouts based on a model with nonconstant standard deviation and a fatigue limit parameter. J Test Eval 25(3):292–301

Sutherland H, Veers P (2000) The development of confidence limits for fatigue strength data. In: 2000 ASME Wind Energy Symposium, pp 1–11

Little RE (1990) Optimal stress amplitude selection in estimating median fatigue limits using small samples. J Test Eval 18(2):115–122

Pascual FG (2003) A standardized form of the random fatigue-limit model. Commun Stat Part B Simul Comput 32(4):1205–1221

Funding

Not applicable

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

I. Hong, Z. Teaford and A. Kahraman declare that they have no competing interests.

Ethical standards

Ethics approval: Not applicable.

Additional information

Availability of data and material

The authors testify that all supporting data is included.

Code availability

Not applicable

Consent to participate

Not applicable.

Consent for publication

All authors consent to the publication of this work.

Rights and permissions

About this article

Cite this article

Hong, I., Teaford, Z. & Kahraman, A. A comparison of gear tooth bending fatigue lives from single tooth bending and rotating gear tests. Forsch Ingenieurwes 86, 259–271 (2022). https://doi.org/10.1007/s10010-021-00510-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-021-00510-w