Abstract

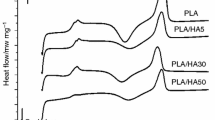

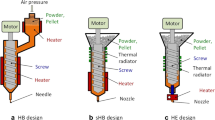

Fused deposition modeling (FDM) has been a widely applied technology as one of the most practical tools of additive manufacturing in terms of industry 4.0. Biopolymer filaments obtained by extrusion can be a promising material for scaffold manufacturing by FDM 3D printers. In this work, composite filaments of polyhydroxybutyrate-cohydroxyvalerate (PHBV) reinforced with ZrO2·nH2O particles were obtained (1–10% wt/wt.) and characterized aiming the production of scaffolds by FDM process. ZrO2·nH2O particles were prepared and mixed to the PHBV in a mini-extruder. The pristine PHBV and composite filaments (PHBV/ZrO2) were characterized by stereomicroscopy, scanning electron microscopy (particle analysis), thermogravimetric analysis (TGA and DSC), X-ray diffractometry, Fourier transformed infrared spectroscopy , Vickers microhardness test (HV), and relative density. The addition of ZrO2·nH2O particles altered the behavior of the PHBV matrix: increased the number of ZrO2·nH2O particles in the composite filament surface, enhanced the amorphous phase and the relative density. The PHBV/7.5%ZrO2 sample presented higher microhardness. It was possible to print the filaments by FDM and the appearance of the scaffolds obtained was a cylindrical structure with rounded inner pores, contributing to the future application in regenerative medicine.

Similar content being viewed by others

References

Dilberoglu UM, Gharehpapagh B, Yaman U, Dolen M (2017) The role of additive manufacturing in the era of industry 4.0. Procedia Manuf 11:545–554

Haleem A, Javaid M (2019) Additive manufacturing applications in industry 4.0: a review. J Ind Integr Manag. https://doi.org/10.1142/s2424862219300011

Kumar A (2018) Methods and materials for smart manufacturing: additive manufacturing, internet of things, flexible sensors and soft robotics. Manuf Lett 15:122–125

Niaki MK, Torabi SA, Nonino F (2019) Why manufacturers adopt additive manufacturing technologies: the role of sustainability. J Clean Prod 222:381–392

Tang Y, Mak K, Zhao YF (2016) A framework to reduce product environmental impact through design optimization for additive manufacturing. J Clean Prod 137:1560–1572

Yang Y, Li L (2018) Total volatile organic compound emission evaluation and control for stereolithography additive manufacturing process. J Clean Prod 170:1268–1278. https://doi.org/10.1016/j.jclepro.2017.09.193

Wu CS, Liao HT (2017) Polyester-based green composites for three-dimensional printing strips: preparation, characterization and antibacterial properties. Polym Bull 74:2277–2295. https://doi.org/10.1007/s00289-016-1836-7

Gebisa AW, Lemu HG (2018) Investigating effects of Fused-deposition modeling (FDM) processing parameters on flexural properties of ULTEM 9085 using designed experiment. Materials (Basel) 11:1–23. https://doi.org/10.3390/ma11040500

Santos-Rosales V, Iglesias-Mejuto A, García-González CA (2020) Solvent-free approaches for the processing of scaffolds in regenerative medicine. Polymers (Basel) 12:533. https://doi.org/10.3390/polym12030533

Alafaghani A, Qattawi A, Ablat MA (2017) Design consideration for additive manufacturing: fused deposition modelling. Open J Appl Sci 07:291–318. https://doi.org/10.4236/ojapps.2017.76024

Mohamed OA, Masood SH, Bhowmik JL (2016) Optimization of fused deposition modeling process parameters for dimensional accuracy using I-optimality criterion. Meas J Int Meas Confed 81:174–196. https://doi.org/10.1016/j.measurement.2015.12.011

Melocchi A, Parietti F, Maroni A et al (2016) Hot-melt extruded filaments based on pharmaceutical grade polymers for 3D printing by fused deposition modeling. Int J Pharm 509:255–263. https://doi.org/10.1016/j.ijpharm.2016.05.036

Mohseni M, Hutmacher DW, Castro NJ (2018) Independent evaluation of medical-grade bioresorbable filaments for fused deposition modelling/fused filament fabrication of tissue engineered constructs. Polymers (Basel). https://doi.org/10.3390/polym10010040

Ceretti E, Ginestra P, Neto PI et al (2017) Multi-layered scaffolds production via fused deposition modeling (FDM) using an open source 3D printer: process parameters optimization for dimensional accuracy and design reproducibility. Procedia CIRP 65:13–18. https://doi.org/10.1016/j.procir.2017.04.042

Ranjan N, Singh R, Ahuja IPS et al (2020) On 3D printed scaffolds for orthopedic tissue engineering applications. SN Appl Sci 2:8–15. https://doi.org/10.1007/s42452-020-1936-8

Boonrungsiman S, Thongtham N, Suwantong O et al (2018) An improvement of silk-based scaffold properties using collagen type I for skin tissue engineering applications. Polym Bull 75:685–700. https://doi.org/10.1007/s00289-017-2063-6

Diermann SH, Lu M, Dargusch M et al (2019) Akermanite reinforced PHBV scaffolds manufactured using selective laser sintering. J Biomed Mater Res Part B Appl Biomater 107:2596–2610. https://doi.org/10.1002/jbm.b.34349

Choi WJ, Hwang KS, Kwon HJ et al (2020) Rapid development of dual porous poly(lactic acid) foam using fused deposition modeling (FDM) 3D printing for medical scaffold application. Mater Sci Eng C 110:110693. https://doi.org/10.1016/j.msec.2020.110693

Kovalcik A, Sangroniz L, Kalina M (2020) Properties of scaffolds prepared by fused deposition modeling of poly(hydroxyalkanoates). Int J Biol Macromol 161:364–376

Saska S, Pires LC, Cominotte MA (2018) Three-dimensional printing and in vitro evaluation of poly(3-hydroxybutyrate) scaffolds functionalized with osteogenic growth peptide for tissue engineering. Mater Sci Eng C 89:265–273

Zubir NHM, Sam ST, Zulkepli NN, Omar MF (2018) The effect of rice straw particulate loading and polyethylene glycol as plasticizer on the properties of polylactic acid/polyhydroxybutyrate-valerate blends. Polym Bull 75:61–76. https://doi.org/10.1007/s00289-017-2018-y

Hamour N, Boukerrou A, Djidjelli H, Beaugrand J (2019) In situ grafting effect of a coupling agent on different properties of a poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/olive husk flour composite. Polym Bull 76:6275–6290. https://doi.org/10.1007/s00289-019-02725-y

da Silva D da CP, de Menezes LR, da Silva PSRC, Tavares MIB (2019) Evaluation of thermal properties of zirconium–PHB composites. J Therm Anal Calorim. https://doi.org/10.1007/s10973-019-09106-7

Dariš B, Knez Ž (2020) Poly(3-hydroxybutyrate): Promising biomaterial for bone tissue engineering. Acta Pharm 70:1–15. https://doi.org/10.2478/acph-2020-0007

Muniyasamy S, Ofosu O, Thulasinathan B et al (2019) Thermal-chemical and biodegradation behaviour of alginic acid treated flax fibres/ poly(hydroxybutyrate-co-valerate) PHBV green composites in compost medium. Biocatal Agric Biotechnol 22:101394. https://doi.org/10.1016/j.bcab.2019.101394

Kaniuk Ł, Krysiak ZJ, Metwally S, Stachewicz U (2020) Osteoblasts and fibroblasts attachment to poly(3-hydroxybutyric acid-co-3-hydrovaleric acid) (PHBV) film and electrospun scaffolds. Mater Sci Eng C. https://doi.org/10.1016/j.msec.2020.110668

Shuai C, Wang C, Qi F et al (2020) Enhanced crystallinity and antibacterial of PHBV scaffolds incorporated with zinc oxide. J Nanomater 2020:6014816. https://doi.org/10.1155/2020/6014816

Rivera-Briso AL, Aachmann FL, Moreno-Manzano V, Serrano-Aroca Á (2020) Graphene oxide nanosheets versus carbon nanofibers: enhancement of physical and biological properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) films for biomedical applications. Int J Biol Macromol 143:1000–1008

Augustine R, Hasan A, Patan NK et al (2020) Cerium oxide nanoparticle incorporated electrospun poly(3-hydroxybutyrate-co-3-hydroxyvalerate) membranes for diabetic wound healing applications. ACS Biomater Sci Eng 6:58–70. https://doi.org/10.1021/acsbiomaterials.8b01352

Carvalho Benini KCC de, Ornaghi HL, de Medeiros NM, et al (2020) Thermal characterization and lifetime prediction of the PHBV/nanocellulose biocomposites using different kinetic approaches. Cellulose 27:7503–7522. https://doi.org/10.1007/s10570-020-03318-z

Malathi AN, Singh AK (2019) Antimicrobial activity of rice starch based film reinforced with titanium dioxide (TiO 2) Nanoparticles. Agric Res J 56:111. https://doi.org/10.5958/2395-146x.2019.00017.6

Anžlovar A, Kržan A, Žagar E (2018) Degradation of PLA/ZnO and PHBV/ZnO composites prepared by melt processing. Arab J Chem 11:343–352. https://doi.org/10.1016/j.arabjc.2017.07.001

Han J, Han C, Cao W et al (2012) Preparation and characterization of biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate)/silica nanocomposites. Polym Eng Sci 52:250–258. https://doi.org/10.1002/pen

Pramanik N, Bhattacharya S, Rath T et al (2019) Polyhydroxybutyrate-co-hydroxyvalerate copolymer modified graphite oxide based 3D scaffold for tissue engineering application. Mater Sci Eng C 94:534–546. https://doi.org/10.1016/j.msec.2018.10.009

Braga NF, Vital DA, Guerrini LM et al (2018) PHBV-TiO2 mats prepared by electrospinning technique: physico-chemical properties and cytocompatibility. Biopolymers 109:1–12. https://doi.org/10.1002/bip.23120

da Costa Reis DC, Lemos Morais AC, de Carvalho LH et al (2016) Assessment of the morphology and interaction of PHBV/Clay bionanocomposites: uses as food packaging. Macromol Symp 367:113–118. https://doi.org/10.1002/masy.201500143

Das M, Balla V (2015) Additive manufacturing and innovation in materials world. Additive manufacturing. Taylor & Francis, New York, pp 297–332

Zhou M, Yu D (2014) Cartilage tissue engineering using PHBV and PHBV/Bioglass scaffolds. Mol Med Rep 10:508–514. https://doi.org/10.3892/mmr.2014.2145

Thiré RMDSM, Arruda LC, Barreto LS (2011) Morphology and thermal properties of poly(3-hydroxybutyrate-co-3. hydroxyvalerate)/attapulgite nanocomposites. Mater Res 14:340–344. https://doi.org/10.1590/S1516-14392011005000046

Noorani B, Khoshraftar A, Yazdian F et al (2018) Fabrication and evaluation of nanofibrous polyhydroxybutyrate valerate scaffolds containing hydroxyapatite particles for bone tissue engineering. Int J Polym Mater Polym Biomater 67:987–995. https://doi.org/10.1080/00914037.2017.1417283

Sridhar V, Lee I, Chun HH, Park H (2013) Graphene reinforced biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate) nano-composites. Express Polym Lett 7:320–328. https://doi.org/10.3144/expresspolymlett.2013.29

Bhowmick A, Pramanik N, Jana P et al (2017) Development of bone-like zirconium oxide nanoceramic modified chitosan based porous nanocomposites for biomedical application. Int J Biol Macromol 95:348–356. https://doi.org/10.1016/j.ijbiomac.2016.11.052

Benini KCCDC (2015) Compósitos De Nanocelulose / Phbv : Manta. UNESP

Mulinari DR, da Silva MLCP (2008) Adsorption of sulphate ions by modification of sugarcane bagasse cellulose. Carbohydr Polym 74:617–620. https://doi.org/10.1016/j.carbpol.2008.04.014

Diermann SH, Lu M, Zhao Y et al (2018) Synthesis, microstructure, and mechanical behaviour of a unique porous PHBV scaffold manufactured using selective laser sintering. J Mech Behav Biomed Mater 84:151–160. https://doi.org/10.1016/j.jmbbm.2018.05.007

Geng P, Zhao J, Wu W et al (2019) Effects of extrusion speed and printing speed on the 3D printing stability of extruded PEEK filament. J Manuf Process 37:266–273. https://doi.org/10.1016/j.jmapro.2018.11.023

Barbosa SE, Kenny JM (2000) Processing of short-fiber reinforced polypropylene. I. Influence of processing conditions on the morphology of extruded filaments. Polym Eng Sci 40:11–22

Costa ILM, Zanini NC, Mulinari DR (2020) Thermal and mechanical properties of HDPE reinforced with Al2O3 nanoparticles processed by thermokinectic mixer. J Inorg Organomet Polym Mater. https://doi.org/10.1007/s10904-020-01709-0

Kariz M, Sernek M, Obućina M, Kuzman MK (2018) Effect of wood content in FDM filament on properties of 3D printed parts. Mater Today Commun 14:135–140. https://doi.org/10.1016/j.mtcomm.2017.12.016

Mallakpour S, Nezamzadeh Ezhieh A (2017) Polymer nanocomposites based on modified ZrO2 NPs and poly(vinyl alcohol)/poly(vinyl pyrrolidone) blend: optical, morphological, and thermal properties. Polym Plast Technol Eng 56:1136–1145. https://doi.org/10.1080/03602559.2016.1253741

Bedi P, Singh R, Ahuja IPS (2018) Effect of SiC/Al2O3 particle size reinforcement in recycled LDPE matrix on mechanical properties of FDM feed stock filament. Virtual Phys Prototyp 13:246–254. https://doi.org/10.1080/17452759.2018.1496605

Singh AK, Patil B, Hoffmann N et al (2018) Additive manufacturing of syntactic foams: part 1: development, properties, and recycling potential of filaments. Jom 70:303–309. https://doi.org/10.1007/s11837-017-2734-7

Díez-Pascual AM, Díez-Vicente AL (2014) ZnO-reinforced poly(3-hydroxybutyrate-co-3-hydroxyvalerate) bionanocomposites with antimicrobial function for food packaging. ACS Appl Mater Interfaces 6:9822–9834. https://doi.org/10.1021/am502261e

Shuai C, Yuan X, Yang W et al (2020) Cellulose nanocrystals as biobased nucleation agents in poly-L-lactide scaffold: crystallization behavior and mechanical properties. Polym Test 85:106458. https://doi.org/10.1016/j.polymertesting.2020.106458

Olsson DC, Pippi NL, Tognoli GK, Raiser AG (2008) Comportamento biológico de matriz scaffold acrescida de células progenitoras na reparação óssea. Ciência Rural 38:2403–2412

Müller D, Heuss-Aßbichler S (2016) Behavior of yttria-stabilized zirconia in the presence of molten salts: part 1 - dissolution and recrystallization phenomena. J Eur Ceram Soc 36:3495–3503. https://doi.org/10.1016/j.jeurceramsoc.2016.05.042

Benini KCC d. C, Cioffi MOH, Voorwald HJC (2017) PHBV/cellulose nanofibrils composites obtained by solution casting and electrospinning process. Rev Mater 22:. https://doi.org/https://doi.org/10.1590/s1517-707620170002.0170

Perveen K, Masood F, Hameed A (2020) Preparation, characterization and evaluation of antibacterial properties of epirubicin loaded PHB and PHBV nanoparticles. Int J Biol Macromol 144:259–266. https://doi.org/10.1016/j.ijbiomac.2019.12.049

Shakil O, Masood F, Yasin T (2017) Characterization of physical and biodegradation properties of poly-3-hydroxybutyrate-co-3-hydroxyvalerate/sepiolite nanocomposites. Mater Sci Eng C 77:173–183. https://doi.org/10.1016/j.msec.2017.03.193

Su Y, Cui H, Li Q et al (2013) Strong adsorption of phosphate by amorphous zirconium oxide nanoparticles. Water Res 47:5018–5026. https://doi.org/10.1016/j.watres.2013.05.044

Cui H, Li Q, Gao S, Shang JK (2012) Strong adsorption of arsenic species by amorphous zirconium oxide nanoparticles. J Ind Eng Chem 18:1418–1427. https://doi.org/10.1016/j.jiec.2012.01.045

Chikere CO, Faisal NH, Kong-Thoo-Lin P, Fernandez C (2020) Interaction between amorphous zirconia nanoparticles and graphite: electrochemical applications for gallic acid sensing using carbon paste electrodes in wine. Nanomaterials 10:537. https://doi.org/10.3390/nano10030537

Singh AK, Nakate UT (2014) Microwave synthesis, characterization, and photoluminescence properties of nanocrystalline zirconia. Sci World J. https://doi.org/10.1155/2014/349457

Calleja FJB (1985) Microhardness relating to crystalline polymers. Adv Polym Sci. https://doi.org/10.1007/3-540-13779-3_19

Pratap B, Gupta RK, Denis L, Goswami D (2020) Evaluation of polymerization shrinkage and vickers hardness for restorative dental composites. Mater Today Proc 21:1563–1565. https://doi.org/10.1016/j.matpr.2019.11.090

Batista KC, Silva DAK, Coelho LAF et al (2010) Soil biodegradation of PHBV/Peach palm particles biocomposites. J Polym Environ 18:346–354. https://doi.org/10.1007/s10924-010-0238-4

Ramrakhiani M, Pal D, Murty TS (1979) Micro-identation hardness studies on human bones. Cell Tissues Organs 103:358–362

Jiang W, Shi J, Li W, Sun K (2012) Morphology, wettability, and mechanical properties of polycaprolactone/hydroxyapatite composite scaffolds with interconnected pore structures fabricated by a mini-deposition system. Polym Eng Sci 52:2396–2402. https://doi.org/10.1002/pen

Taboas JM, Maddox RD, Krebsbach PH, Hollister SJ (2003) Indirect solid free form fabrication of local and global porous, biomimetic and composite 3D polymer-ceramic scaffolds. Biomaterials 24:181–194. https://doi.org/10.1016/S0142-9612(02)00276-4

Lam CXF, Mo XM, Teoh SH, Hutmacher DW (2002) Scaffold development using 3D printing with a starch-based polymer. Mater Sci Eng C 20:49–56. https://doi.org/10.1016/S0928-4931(02)00012-7

Yao Q, Wei B, Guo Y et al (2015) Design, construction and mechanical testing of digital 3D anatomical data-based PCL–HA bone tissue engineering scaffold. J Mater Sci Mater Med. https://doi.org/10.1007/s10856-014-5360-8

Thavornyutikarn B, Chantarapanich N, Sitthiseripratip K (2014) Bone tissue engineering scaffolding: computer-aided scaffolding techniques. Progr Biomater 3(2):61–102

Wei X, Luo Y, Huang P (2019) 3D bioprinting of alginate scaffolds with controlled micropores by leaching of recrystallized salts. Polym Bull 76:6077–6088. https://doi.org/10.1007/s00289-019-02690-6

Andrade GS, Andrade D de B, de Lima GG (2020) TECHNOLOGICAL FORECASTING OF CHITOSAN, SILK FIBROIN AND XANTHAN GUM AS BIOMATERIALS FOR SCAFFOLDS-3D. Rev GEINTEC– ISSN 10:5279–5288. https://doi.org/10.7198/geintec.v10i1.1173

Marinho SBN, Gomes D do N, Lima CS de A (2019) Caracterização de scaffold poroso obtido pela técnica de freezecasting. In: Anais do III Simpósio de Inovação em Engenharia Biomédica - SABIO 2019 W. pp 46–43

Acknowledgements

The authors are grateful for the research support by FAPERJ (process E-26 /260.026/ 2018 and E-26 /010.001800/2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Carvalho, J.G., Zanini, N.C., Claro, A.M. et al. Composite filaments OF PHBV reinforced with ZrO2·nH2O particles for 3D printing. Polym. Bull. 79, 2113–2132 (2022). https://doi.org/10.1007/s00289-021-03610-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03610-3