Abstract

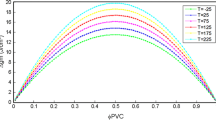

Temperature-responsive flat composite ultrafiltration membranes were prepared by dry–wet phase inversion process from casting solution of polyacrylonitrile and hydrophobically modified polyvinyl alcohol (HMPVA) in dimethylsulfoxide solvent. HMPVA is characterized by multiple reversible temperature-stimulated change of its physicochemical properties with the temperature of transformation (T tr) being dependent on the degree of acetalization. Based on the dynamic viscosity, the limit of the polymer concentration in the solution was established to be from 0.6 to 3.5 wt% for HMPVA at constant concentration of 16 wt% PAN. HMPVA remained homogeneously scattered within the membrane structure which was proved by Fourier transform infrared spectroscopy (FTIR). The studies on membrane morphology by scanning electron microscopy and on permeability (J, l/m2 h) and rejection (R, %) for water and albumin showed an asymmetry of the porous structure with pores having capillary macroporosity—on the surface and inner walls of the pores. The optimal for membrane parameters is a concentration of 1.2 wt% HMPVA. The permeability to water at 0.3 MPa changes from 58 to 80 l/m2 h and permeability to albumin—from 30 to 56 l/m2 h, when changing the temperature relative to T tr = 29.5 °C. Adjusting the temperature, it allows us to control the amount of flow passing through the membrane and widens the possibilities for self-cleaning and regenerations of the membrane.

Similar content being viewed by others

References

Ulbricht M (2006) Advanced functional polymer membranes. Polymer 47:2217–2262. doi:10.1016/j.polymer.2006.01.084

Debashish R, Cambre JN, Sumerlin BS (2010) Future perspectives and recent advances in stimuli-responsive materials. Prog Polym Sci 35:278–301. doi:10.1016/j.progpolymsci.2009.10.008

Bhattacharyya D, Schafer T, Wickramasinghe SR, Daunert S (2013) Responsive membranes and materials. Wiley, Amsterdam

Mondal S (2014) Stimuli responsive surfaces for fouling-resistant polymeric membranes. J Membr Sci Technol 4:e120. doi:10.4172/2155-9589.1000e120

Gorey CM (2008) Grafting of stimuli-responsive polymer films to ultrafiltration membranes. Dissertation, University of Toledo

Fei ZD, Wan LS, Wang WM, Zhong MQ, Xu ZK (2013) Thermo-responsive polyacrylonitrile membranes prepared with poly(acrylonitrile-g-isopropylacrylamide) as an additive. J Membr Sci 432:42–49. doi:10.1016/j.memsci.2013.01.008

Wandera D, Wickramasinghe RS, Husson SM (2010) Stimuli-responsive membranes. J Membr Sci 357:6–35. doi:10.1016/j.memsci.2010.03.046

Liu F, Hashim NA, Liu YT, Abed MRM, Li K, Liu Y, Moghareh AMR (2011) Progress in the production and modification of PVDF membranes. J Membr Sci 375:1–27. doi:10.1016/j.memsci.2011.03.014

Lee A, Elam J, Darling S (2016) Membrane materials for water purification: design, development and application. Environ Sci Water Res Technol 2:17–42. doi:10.1039/c5ew00159e

Gandhi A, Paul A, Sen SO, Sen KK (2015) Studies on thermoresponsive polymers: phase behaviour, drug delivery and biomedical applications. Asian J Pharm Sci 10:99–107. doi:10.1016/j.ajps.2014.08.010

Liu Z, Wang W, Xie R, Ju XJ, Chu LY (2016) Stimuli-responsive smart gating membranes. Chem Soc Rev 45:460–475. doi:10.1039/C5CS00692A

Santoro S, Moro AJ, Portugal CAM, Crespo JG, Coelhoso IM, Lima JC (2016) Development of oxygen and temperature sensitive membranes using molecular probes as ratiometric sensor. J Membr Sci 514:467–475. doi:10.1016/j.memsci.2016.05.019

Christova D, Ivanova S, Ivanova G (2003) Water-soluble temperature-responsive poly(vinyl alcohol-co-vinyl acetal)s. Polym Bull 50:367–372. doi:10.1007/s00289-003-0178-4

Jung B, Yoon JK, Kim B, Rhee HW (2004) Effect of molecular weight of polymeric additives on formation, permeation properties and hypochlorite treatment of asymmetric polyacrylonitrile membranes. J Membr Sci 43:45–57. doi:10.1016/j.memsci.2004.06.011

Dave YG, Reddy AVR (2011) Preparation, characterization, acid stability and organic fouling of poly(acrylonitrile-co-methacrylic acid) ultrafiltration membranes. Desalination 282:9–18. doi:10.1016/j.desal.2011.08.055

Tang CC, Yun YB, Mao JC, Yu LZ, Wang LH (2010) Performance study on polysulfone-polyacrylonitrile blend ultrafiltration membranes. J Beijing For Univ 32:271–275

Slavova V (2013) Scientific research of the influence of the vacuum metalling over the operational characteristics of the ultrafiltering polymer. GJRA 2:40–41. doi:10.15373/22778160

Petrov St, Ivanova T, Christova D, Ivanova S (2005) Modification of polyacrylonitrile membranes with temperature sensitive. J Membr Sci 261:1–6. doi:10.1016/j.memsci.2004.12.029

Scott K Handbook of Industrial membranes, 2nd edn. Elsevier, Amsterdam

Lali BS, Kochkodan V, Hashaikeh R, Hilal N (2013) A review on membrane fabrication: structure, properties and performance relationship. Desalination 326:77–95. doi:10.1016/j.desal.2013.06.016

Jung B, Yoon JK, Kim B, Rhee HW (2004) Effect of molecular weight of polymeric additives on formation, permeation properties and hypochlorite treatment of asymmetric polyacrylonitrile membranes. J Membr Sci 243:45–57. doi:10.1016/j.memsci.2004.06.011

Aroon MA, Ismail AF, Montazer-Rahmati MM, Matsuura T (2010) Morphology and permeation properties of polysulfone membranes for gas separation: effects of non-solvent additives and co-solvent. Sep Purif Technol 72:194–202. doi:10.1016/j.seppur.2010.02.009

Lohokare H, Bhole Y, Taralkar S, Kharul U (2011) Poly(acrylonitrile) based ultrafiltration membranes: optimization of preparation parameters. Desalination 282:46–53. doi:10.1016/j.desal.2011.04.009

Hołda AK, Aernouts B, Saeys W, Vankelecom IFJ (2013) Study of polymer concentration and evaporation time as phase inversion parameters for polysulfone-based SRNF membranes. J Membr Sci 442:196–205. doi:10.1016/j.memsci.2013.04.017

Sun W, Chen C, Li J, Lin Y (2009) Ultrafiltration membrane formation of PES-C, PES and PPESK polymers with different solvents. Chin J Polym Sci 27:165–172. doi:10.1142/S0256767909003790

Malkin A, Lyin S, Roumyantseva T, Kulichikhin V (2013) Rheological evidence of gel formation in dilute poly(acrylonitrile) solutions. Macromolecules 1:257–266. doi:10.1021/ma301423u

Zhu G, Wang F, Xu K, Gao Q, Liu Y (2013) Study on properties of poly(vinyl alcohol)/polyacrylonitrile blend film. Polímeros 23:146–151. doi:10.4322/polimeros.2013.076

Hilbe W (2016) Stimulus-active polymer actuators for next-generation microfluidic devices. Appl Phys A 122:751. doi:10.1007/s00339-016-0258-6

Tokarev I, Minko S (2010) Stimuli-responsive porous hydrogels at interfaces for molecular filtration, separation, controlled release, and gating in capsules and membranes. Adv Mater 22:3446–3462. doi:10.1002/adma.201000165

Lokuge I, Wang X, Bohn PW (2007) Temperature-controlled flow switching in nanocapillary array membranes mediated by poly(N-isopropylacrylamide) polymer brushes grafted by atom transfer radical polymerization. Langmuir 23:305–311. doi:10.1021/la060813m

Xiao L, Isner A, Waldrop K, Saad A, Takigawa D, Bhattacharyya D (2014) Development of bench and full-scale temperature and pH responsive functionalized PVDF membranes with tunable properties. J Membr Sci 457:39–49. doi:10.1016/j.memsci.2014.01.033

Sadrzadeh M, Bhattacharjee S (2013) Rational design of phase inversion membranes by tailoring thermodynamics and kinetics of casting solution using polymer additives. J Membr Sci 441:31–44. doi:10.1016/j.memsci.2013.04.009

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miteva, M., Christova, D., Ivanova, S. et al. Effect of hydrophobically modified PVA on the temperature-responsive structure and permeation of PAN-based composite ultrafiltration membranes. Polym. Bull. 75, 2805–2817 (2018). https://doi.org/10.1007/s00289-017-2182-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2182-0