Abstract

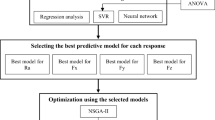

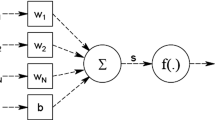

This paper focuses on optimisation of process parameters of the turning operation, using artificial intelligence techniques such as support vector regression (SVR) and artificial neural networks (ANN) integrated with genetic algorithm (GA). The model is trained using the turning parameters as the input and corresponding surface roughness, tool wear and power required as the output. Data, obtained from conducting experiments is analysed using support vector machine (SVM) and artificial neural network. SVM, a nonlinear model, is learned by linear learning machine by mapping into high-dimensional kernel-induced feature space. The genetic algorithm is integrated with these to find the optimum from the response surface generated. The results are compared with those obtained by integrating GA with traditional models like response surface methodology (RSM) and regression analysis (RA). This paper illustrates the impact that techniques based on artificial intelligence have on optimising processes.

Similar content being viewed by others

References

Lambert B, Walvekar A (1978) Optimisation of multi pass machining operations. Int J Prod Res 16(4):259–265

Gopalakrishan B, Al-Khayyal F (1897–1908) Machine parameter selection for turning with constraints: an analytical approach based on geometric programming. Int J Prod Res 29(9):1991

Gupta R, Batra J, Lal G (1995) Determination of optimal subdivisions of depth of cut in multi pass turning with constraints. Int J Prod Res 33(9):2555–2565

Al-Ahmari AMA (2001) Mathematical model for determining machining parameters in multipass turning operations with constraints. Int J Prod Res 39(15):3367–3376

Chandrasekaran M et al (2010) Application of soft computing techniques in machining performance prediction and optimization: a literature review. Int J Adv Manuf Technol 46:445–464

Asiltürk (2012) Predicting surface roughness of hardened AISI 1040 based on cutting parameters using neural networks and multiple regression, Int J Adv Manuf Technol, Online-First

Gupta AK (2010) Predictive modelling of turning operations using response surface methodology, artificial neural networks and support vector regression. Int J Prod Res 48(3):763–778

Lela B et al (2009) Regression analysis, support vector machines, and Bayesian neural network approaches to modeling surface roughness in face milling. Int J Adv Manuf Technol 42:1082–1088

Davim JP (2003) Design of optimisation of cutting parameters for turning metal matrix composites based on the orthogonal arrays. J Mater Process Technol 132(1):340–344

Choudhury I, El-Baradie M (1999) Machinability assessment of inconel 718 by factorial design of experiment coupled with response surface methodology. J Mater Process Technol 95(1):30–39

Chien W, Chou C (2001) The predictive model for machinability of 304 stainless steel. J Mater Process Technol 118(1–3):441–447

Ozel T, Karpat Y (2005) Predictive modelling of surface roughness and tool wear in hard turning using regression and neural networks. Int J Mach Tools Manuf 45(4–5):467–479

Al-Ahmari AMA (2007) Prediction and optimisation models for turning operations. Int J Prod Res 46(15):4061–40811

Judong S et al (2006) Modelling and analysis of waviness reduction in soft-pad grinding of wire-sawn silicon wafers by support vector regression. Int J Prod Res 44(13):2605–2623

http://www.minitab.com/en-us/ Minitab Inc. (2006)

Kecman V (2001) Learning and soft computing. MIT Press, Cambridge

Parrella (2007) Online support vector regression. a thesis presented for the degree of information science. University of Genoa, Italy

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, A.K., Guntuku, S.C., Desu, R.K. et al. Optimisation of turning parameters by integrating genetic algorithm with support vector regression and artificial neural networks. Int J Adv Manuf Technol 77, 331–339 (2015). https://doi.org/10.1007/s00170-014-6282-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6282-9