Abstract

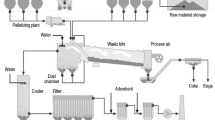

Discussed is the INMETCO processing of electric arc furnace (EAF) baghouse dusts from the specialty-steel and low-alloy industries. In addition, the INMETCO process has been modified to recover nickel, chromium and iron from many other waste materials including:

-

pickling solutions or filter cakes

-

spent nickel and chromium plating baths

-

carbon refractories from pickling tanks, and

-

superalloy wastes including baghouse bags.

INMETCO is the only North American company presently capable of recycling nickel-cadmium batteries by high-temperature metals recovery. This process and the details of INMETCO’s best demonstrated available technology (BDAT) test program are discussed.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

SME preprint 92-209, SME Annual Meeting, Feb. 24–27, 1992, Phoenix, AZ. M&MP paper 92-620.

Discussion of this paper must by submitted, in duplicate, prior to Feb. 28, 1993.

Rights and permissions

About this article

Cite this article

Hanewald, R.H., Munson, W.A. & Schweyer, D.L. Processing EAF dusts and other nickel-chromium waste materials pyrometallurgically at INMETCO. Mining, Metallurgy & Exploration 9, 169–173 (1992). https://doi.org/10.1007/BF03403430

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03403430