Abstract

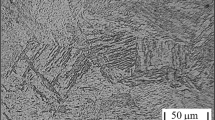

Ball mills are commonly used for regrinding operations in the mineral processing industry. However, efforts are now being made to use stirred mills for regrinding, particularly in instances where very fine grinding is required. Media type (steel shot, glass beads, alumina balls and crushed quartz), media size, mill speed and the number of passes required to obtained the target product size are studied. The product size and energy consumption are used in the evaluation of the test results. The grinding media size, shape, density, filling ratio, mill circumferential speed and grinding time play distinct roles in product size fineness.

Similar content being viewed by others

References

Becker, M., Kwade, A., and Schwedes, J., 2001, “Stress intensity in stirred media mills and its effect on specific energy requirement,” International Journal of Mineral Processing, Vol. 61, pp. 189–208.

Conley, R.F., 1983, “Attrition milling of industrial minerals,” Conference proceeding of the ultrafine grinding and separation of industrial minerals, Malghan, S.C., ed., SME-AIME, New York, pp. 37–48.

Davey, G., 2003, “Fine copper grinding using the Metso Stirred Media Detritor,” Preprint 03-086, Presented at the SME Annual Meeting, Cincinnati, Ohio, USA, February 24–26.

Enderle, U., Woodall, P., Duffy, M., and Johnson, N.W., 1997, “Stirred mill technology for regrinding McArthur River and Mount Isa zinc/lead ores,” XX International Mineral Processing Congress, Aachen, Germany, September 21–26, Vol. 2, pp. 71–78.

Gao, M., Young, M.F., Cronin, B., and Harbort, G., 2000, “IsaMill medium competency and its effect on milling performance,” Preprint 00-034, Presented at the SME Annual Meeting, Salt Lake City, Utah, Feb. 28-March 1.

Harbort, G., Murphy, A., Vargas, A., and Young, M.F., 1999, “The introduction of the IsaMill for ultrafine grinding in the Mt Isa Lead/Zinc Concentrator,’ Extemin99, Arequipa, Peru, September.

Jankovic, A., 2003, “ Variable affecting the fine grinding of minerals using stirred mills,” Minerals Engineering, Vol. 16, pp. 337–345.

Orumwense, O.A., and Forssberg, E., 1990, “Ultrafine grinding in an annular ball mill,” Kona, Vol. 8, pp. 125–130.

Stehr, N., 1989, “New advances in micro-fine wet grinding and dispersion,” Paper presented during the short course on dispersion of pigments and resins in fluid media, Kent State University, Kent, Ohio, USA, May 8–12.

Young, M.F. and Gao, M., 2000, “Performance of the IsaMill in the George Fisher flowsheet,” AusIMM Seven Mill Operators Conference, Kalgoorlie, Australia, October 12–14.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Orumwense, A.O. Effect of media type on regrinding with stirred mills. Mining, Metallurgy & Exploration 23, 40–44 (2006). https://doi.org/10.1007/BF03403334

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03403334