Abstract

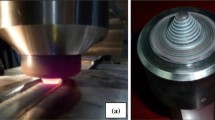

Friction stir welding (FSW) has gained increasing interest since its invention at TWI some 13 years ago. The continuing development of the process is described. The design of the tool is the key to the successful application of the FSW process and its ability to accommodate a range of aluminium alloys over a wider range of thickness. A key factor in tool technology is the ratio between the volume swept by the probe and the volume of the probe itself. This paper will focus on fatigue performance of lap welds made with rotary Skew-stir™ and reversal Skew-stir™ techniques.

Similar content being viewed by others

References

Thomas W.M., Nicholas E.D., Needham J.C., Murch M.G., Temple-Smith P., Dawes C.J. (TWI): Improvements relating to friction welding, European Patent Specification EP 0 615 480 B1.

Brooker M. J., van Deudekom A.J.M., Kallee S.W., Sketchley P.D.: Applying friction stir welding to the Ariane 5 main motor thrust frame, Fokker Paper, European Conference on Spacecraft Structures, Materials and Mechanical Testing, 29 November–1 December 2000, Estec, Noordwijk, The Netherlands.

Cederqvist L., Reynolds A. P.: Properties of friction stir welding aluminium lap joints, TWI 2nd International Symposium on Friction Stir Welding, 26–28 June 2000, Gothenburg, Sweden.

Cederqvist L., Reynolds A.P.: Factors affecting the properties of friction stir welded aluminum lap joints, Welding Research Supplement, December 2001, pp. 281–287.

Matsumoto K., Sasabe S.: Lap joints of aluminium alloys by friction stir welding, TWI 3rd International Symposium on Friction Stir Welding, Kobe, Japan, 27–28 September 2001.

Christner B.: Developments and testing of friction stir welding (FSW) as a joining method for primary aircraft structure, ICAS congress 2002.

Thomas W.M., Norris I.M., Smith I.J., Staines D.G.: Reversal stir welding — Re-stir™ — Feasibility Study, 4th International Symposium of Friction Stir welding, Park City, Utah, USA, 14–16 May 2003.

Thomas W.M., Staines D.G., Johnson K.I., Evans P.: ‘Com-stir™ — Compound motion for friction stir welding and machining, published on the Internet 6 March 2003. http://www.twi.co.uk/j32k/unprotected/pdfs/spwmtmar2003.pdf.

Watts E.R., Staines D.G., Thomas W.M., Nicholas E.D.: Dual-rotation stir welding — Preliminary trials, published on the Internet April 8th 2004, TWI Ltd Granta Park, Great Abington, Cambridge, CB1 6AL, United Kingdom. http://www.twi.co.uk/j32k/getFile/sperwapr2004.pdf.

Thomas W.M., Braithwaite A.B.M., John R.: Skew-Stir™ technology. TWI 3rd International Symposium on Friction Stir Welding, Kobe, Japan, 27–28 September 2001.

Cantin G. M.D., David S.A., Thomas W.M., Lara-Curzio E., Babu S.S.: Friction skew-stir welding of lap joints in 5083-O Aluminium Part 1: Microstructural Characterisation, Science Technology Welding Joining, journal, to be published.

Dalle Donne C., Raimbeaux G., Biallas G., Allehaux D., Palm F., Ghidini T.: Fatigue properties of friction stir welded aluminium butt joints, ICAF 2003 — Fatigue of Aeronautical Structures as an Engineering Challenge, The 22nd Symposium, International Committee on Aeronautical Fatigue, Switzerland, May 2003.

Vaidya W.V., Angamuthu K., Ventzke V., Kocak M., Palm F.: Fatigue and fracture behaviour of friction stir welded aluminium alloy AA6056-T6, ICAF 3003-Fatigue of Aeronautical Structures as an Engineering Challenge. The 22nd Symposium, International Committee on Aeronautical Fatigue, Switzerland, May 2003.

Thomas W.M., Johnson K.I., Wiesner C.S.: Friction stir welding — Recent develpments in tool and process technologies, Advanced Engineering Materials 2003, 5 No. 7 C35.

Dolby R.E., Johnson K.I., Thomas W.M.: The joining of aluminium extrusions, aluminium two thousand, 5th World Congress, Rome, 2003.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Thomas, W., Nicholas, E.D., Staines, D. et al. FSW Process Variants and Mechanical Properties. Weld World 49, 4–11 (2005). https://doi.org/10.1007/BF03266468

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266468