Abstract

In order to evaluate the stress corrosion cracking resistance for commercial alloys (C600MA, C600TT, C690TT) and Korean-made alloys (K600MA, K690TT), C-ring tests were performed in a caustic environment of 4, 10, 20, 30, and 50% NaOH solution at 315°C, for 480 h with an applied potential of 125 mV vs. OCP. Different stress corrosion cracking phenomena were observed according to the NaOH concentration. The rate of caustic IGSCC attack did not appear to increase monotonically with caustic concentrations, but peaked at a concentration between 4 and 50% caustic, or approximately 30% NaOH. Intergranular stress corrosion cracking was found for C600MA in 10, 20, and 30% NaOH solutions, while no cracking was observed in the 4 and 50% NaOH solutions. In 30% NaOH solution, transgrnular stress corrosion cracking was detected in C690TT, which may be related with the large amount of plastic strain (150% yield) and the applied potential (125 mV vs. OCP). The overall data clearly indicate that C600MA has the worst SCC resistance while K690TT offers the best resistance. There is also fairly good correlation between the caustic SCC susceptibility and some metallurgical parameters, particularly the grain size and the yield strength at room temperature. Specifically, materials having larger grain size and lower yield strength exhibited higher caustic SCC resistance.

Similar content being viewed by others

References

S. J. Green and J. P. N. Paine,Nuclear Technology 55, 10 (1981).

G. P. Airey and F. W. Pement,Corrosion 39, 46 (1983).

G. P. Airey,Optimization of Metallurgical Variables to Improve the Stress Corrosion Resistance of Inconel 600, EPRI NP-3051, Electric Power Research Institute, Palo Alto, CA, USA (1983).

K. Norring, J. Engstrom and P. Norberg,Proceedings of the 3rd International Symposium on Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors (eds. G. J. Theus and J. R. Weeks), p. 587, The Metallurgical Society, Traverse City (1987).

G. P. Airey,Corrosion 35, 129 (1979).

S. Suzuki,Proceedings of the 5th International Symposium on Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors (ed. American Nuclear Society), p. 861, The Metallurgical Society, Monterey (1991).

H. P. Kim, S. S. Hwang, Y. S. Kim, I. H. Kuk, and J. S. Kim,Met. Mater.-Int. 7, 1 (2001).

T. Tsuruta, S. Okamoto, T. Kitera, H. Takamatsu, and T. Matsunaga,Proceedings of the 7th International Symposium on Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors (eds. G. Aireyet al.), p. 187, The Metallurgical Society, Breckenridge (1995).

H. Kawamura and H. Hirano,Proceedings of the 6th International Symposium on Environmental Degradation of Materials in Nuclear Power Systems-Water Reactors (ed. American Nuclear Society), p. 71, The Metallurgical Society, Sandiego (1993).

J. P. N. Paine, R. S. Pathania, and C. E. Shoemaker,Proceedings of the 3rd International Symposium on the Environmental Degradation of Materials in Nuclear Power Plants-Water Reactors (eds. G. J. Theus and J. R. Weeks), p. 501, The Metallurgical Society, Traverse City (1987).

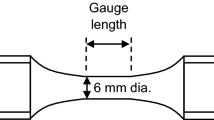

ASTM G38,Standard practice for making and using Cring stress-corrosion lest specimens, Annual Book of ASTM Standards, 3.02, ASM (1984).

S. S. Hwang, Y. S. Park, I. S. Jeong, S. Y. Hong, and U. C. Kim,J. Corros. Sci. Soc. of Korea 25, 327 (1996).

R. J. Jacko,Corrosion Evaluation of Thermally Treated Alloy 600 Tubing in Primary and Faulted Secondary Water Environments, EPRI NP-6721-SD, Electric Power Research Institute, Palo Alto, CA, USA, June (1990).

A. K. Agrawal and J. P. N. Paine,Steam Generator Reference Book, p. 15–1, EPRI TR-103824, Electric Power Research Institute, Palo Alto, CA, USA (1994).

G. Pinard-Legry and G. Plante,Intergranular Attack of Alloy 600: Laboratory Investigations, EPRI NP-4223, Electric Power Research Institute, Palo Alto, CA, USA (1985).

D. Van Rooyen and R. Bandy,Mechanism of Intergranular Attack and Stress Corrosion Cracking of Alloy 600 by High Temperature Caustic Solution Containing Impurities, EPRI NP-5129, Electric Power Research Institute, Palo Alto, CA, USA, (1987).

W. M. Connor, R. G. Aspden, R. Hermer, and N. Pessall,Neutralization of Tubesheet Crevice Corrosion, EPRI NP-3040, Electric Power Research Institute, Palo Alto, CA, USA (1983).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, IG., Lee, CS., Hwang, SS. et al. Caustic stress corrosion cracking of alloys 600 and 690 with NaOH concentrations. Met. Mater. Int. 11, 401–409 (2005). https://doi.org/10.1007/BF03027511

Issue Date:

DOI: https://doi.org/10.1007/BF03027511