Abstract

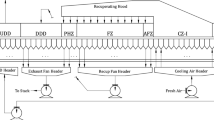

Induration (drying and hardening) of iron ore pellets is an energy-intensive feed preparation step for both the blast furnace and direct reduction routes to iron. It is commonly carried out by a ‘grate/kiln’ process. A mathematical model of the process is described, in which mechanistic models of the grate furnace, kiln, and cooler are linked to enable simulation of the entire process. The model includes equations for the gas stream pressure balances and process controller responses, and provides dynamic solutions. The validation of the model for an operating plant is discussed and steady-state solutions are compared with data from the plant.

Similar content being viewed by others

References

M. Cross, R. W. Young, P. E. Wellstead, and R. D. Gibson:Agglomeration 77, K. V. S. Sastry, ed., Second International Symposium on Agglomeration, Atlanta, GA, 1977, pp. 403–24.

J. A. Thurlby, R. J. Batterham, and R. E. Turner:Agglomeration 81, O. Molerus and W. Hufnagel, eds., Third International Symposium on Agglomeration, Nuremberg, 1981, pp. B23-B35.

J. A. Thurlby, A. L. Morrison, J. K. Wright, R. J. Batterham, and R. E. Turner:Proceedings, Thirteenth Congress, Council of Mining and Metallurgical Institutions, Singapore, 1986, pp. 155–61.

J. R. Wynnyckyj and R.J. Batterham:Agglomeration 85, C.E. Capes, ed., Fourth International Symposium on Agglomeration, Toronto, ON, 1985, pp. 957–94.

N. A. Hasenack, P. A. M. Lebelle, and J. J. Kooy:Mathematical Process Models in Iron and Steelmaking, The Metals Soc., London, 1975, pp. 6–16.

J. A. Thurlby, R. J. Batterham, and R. E. Turner:Inter. J. Mineral Processing, 1979, vol. 6, pp. 43–64.

M. Cross, E. C. Bogren, J. S. Wakeman, and R. D. Frans:Application of Mathematical and Physical Models in the Iron and Steel Industry, L. G. Kuhn, J. W. Hlinka, C. M. Hiles, and J. K. Brimacombe, eds., Iron Steel Soc., AIME, 1982, pp. 101–09.

T. E. Norgate, J. A. Thurlby, R.J. Batterham, and B.C. Povey:Agglomeration 85, C.E. Capes, ed., Fourth International Symposium on Agglomeration, Toronto, 1985, pp. 721–28.

R. W. Young, M. Cross, and R. D. Gibson:Ironmaking and Steelmaking, 1979, vol. 6, no. 1, pp. 1–13.

J. A. Thurlby:Metall. Trans. B, 1988, vol. 19B, pp. 113–21.

J. A. Thurlby:Metall. Trans. B, 1988, vol. 19B, pp. 123–32.

S. Ergun:Chem. Eng. Prog., 1952, vol. 48, no. 2, pp. 89–94.

J. A. Thurlby and R.J. Batterham:Trans. Instn. Min. Metall., Sect. C, 1980, vol. 89, pp. C125-C131.

G.J. Thornton and R.J. Batterham:Chemeca 82, Tenth Australian Chemical Engineering Conference, 1982, The Institution of Engineers, Australia, National Publication No. 82/9, pp. 260–66.

M. Cross amd R. W. Young:Ironmaking and Steelmaking, 1976, vol. 3, no. 3, pp. 129–37.

J. P. Gorog, J. K. Brimacombe, and T. N. Adams:Metall. Trans. B, 1981, vol. 12B, pp. 55–70.

W.E. Ranz:Chem. Eng. Prog., 1952, vol. 48, pp. 247–53.

M.A. Field, D.W. Gill, B.B. Morgan, and P.G.W. Hawksley:Combustion of Pulverized Coal, The British Coal Utilisation Research AsSoc.iation, 1967, p. 343.

D. Papanastassiou and G. Bitsianes:Metatl. Trans., 1973, vol. 4, pp. 487–96.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Thurlby, J.A. A dynamic mathematical model of the complete grate/kiln iron–ore pellet induration process. Metall Trans B 19, 103–112 (1988). https://doi.org/10.1007/BF02666496

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02666496