Abstract

Energy redistributed and absorbed in the cavity produced by a high-intensity beam during drilling and welding is systematically and quantitatively investigated. The incident energy flux is assumed to be a realistic Gaussian distribution, and the cavity is idealized by a paraboloid of revolution having both specular and diffuse reflectivities. By using a Monte Carlo method, the results show that the energy absorbed by the cavity wall deviates markedly from the Gaussian distribution. Effects of the cavity depth-to-opening radius ratio, absorptivity, and specular reflectivity on the absorbed energy are presented. A comparison of incident energy fluxes of uniform and Gaussian distributions is also made.

Similar content being viewed by others

Abbreviations

- b :

-

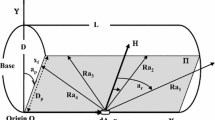

local Cartesian coordinate, as shown in Fig. 2

- f :

-

focal distance = ĝ/r0, as shown in Fig. 3(a)

- g :

-

function describing cavity surface = ĝ/r0, as shown in Fig. 2

- g’ :

-

dg/dr

- h :

-

cavity depth = ĥ/r0

- i, j, k:

-

Cartesian coordinate vectors

- n:

-

local Cartesian coordinate vector, as shown in Fig. 2

- N b :

-

number of energy bundles

- N e :

-

subdivisions of incident flux in a ring element

- N r :

-

number of ring elements

- q :

-

incident flux, as defined in Eq. [3]

- q a :

-

dimensionless energy flux absorbed by cavity wall

- Q :

-

beam power

- r :

-

radial coordinate =r/r 0

- R:

-

position vector = R/r0

- R ij , Rij :

-

magnitude and directional vector of energy bundle,R ij =R ij /r 0, Rij = Rij/r0, as shown in Fig. 2

- R′ ij , R’ij :

-

magnitude and direction of specularly reflected rayR′ ij =R′ ij /r 0, R′ij = R′ij/r0, as shown in Fig. 2

- r0 :

-

cavity opening radius

- r s :

-

a critical radius = rs/r0, as illustrated in Fig. 3(a)

- t:

-

local Cartesian coordinate vector, as shown in Fig. 2

- x, y, z :

-

Cartesian coordinates,x = x/r0,y = ŷ/r0,z = ž/r 0, as shown in Fig. 2

- α, α o :

-

absorptivity and apparent absorptivity defined in Eq. [4]

- θ:

-

angle, as shown in Fig. 2

- p d,p s :

-

diffuse and specular reflectivity

- σ :

-

energy distribution parameter = σ/ro

- ϕ :

-

angle, as shown in Fig. 2

- ^:

-

dimensional quantity

- ′:

-

angles defined in local Cartesian coordinates, as shown in Fig. 2

- i :

-

originating point

- j :

-

striking point

References

P.S. Wei and L.R. Chiou:ASME J. Heat Transfer, 1988, vol. 110, pp. 918–23.

W.H. Giedt and L.N. Tallerico:Weld. J., 1988, vol. 67, pp. 299-s–304-s.

P.S. Wei, T.H. Wu, and Y.T. Chow:ASME J. Heat Transfer, 1990, vol. 112, pp. 163–69.

Y. Arata:Plasma, Electron and Laser Beam Technology, ASM, Metals Park, OH, 1986, pp. 217–25.

C.E. Albright:Trends in Welding Research in the United States, S.A. David, ed., ASM, Metals Park, OH, 1982, pp. 653–65.

E.M. Sparrow:ASME J. Heat Transfer, 1962, vol. 84, pp. 283–93.

E.M. Sparrow and V.K. Jonsson:J. Appl. Mech., 1963, vol. 85, pp. 237–44.

E.M. Sparrow, E.R.G. Eckert, and V.K. Jonsson:ASME J. Heat Transfer, 1962, vol. 84, pp. 294–300.

R.A. Seban:ASME J. Heat Transfer, 1962, vol. 84, pp. 299–300.

H.H. Safwat:ASME J. Heat Transfer, 1970, vol. 92, pp. 198–201.

J.R. Howell and R.E. Durkee:ASME J. Heat Transfer, 1971, vol. 93, pp. 129–35.

J.R. Howell:Advances in Heat Transfer, T.F. Irvine, Jr. and J.P. Hartnett, eds., Academic Press, New York, NY, 1968, vol. 5, pp. 1–54.

J.S. Toor and R. Viskanta:Int. J. Heat Mass Transfer, 1968, vol. 11, pp. 883–97.

G.K. Hicken, W.H. Giedt, and A.E. Bentley:Weld. J., 1991, vol. 70, pp. 69-s–75-s.

D.A. Schauer, W.H. Giedt, and S.M. Shintaku:Weld. J., 1978, vol. 57, pp. 127-s–133-s.

P.S. Wei and J.Y. Ho:Int. J. Heat Mass Transfer, 1990, vol. 33, pp. 2207–17.

Metals Handbook, 9th ed., E.F. Nippes, coordinator, ASM, Metals Park, OH, 1983, vol. 6, pp. 649–51.

E.M. Sparrow and R.D. Cess:Radiation Heat Transfer, Brooks/ Cole, Belmont, CA, 1966, chs. 1 and 7.

M.M. Collur and T. Debroy:Metall. Trans. B, 1989, vol. 20B, pp. 277–86.

D.G. Burkhard, D.L. Sheal, and R. Sexl:Int. J. Heat Mass Transfer, 1973, vol. 16, pp. 271–80.

M.H.N. Naraghi: Ph.D. Thesis, University of Akron, Akron, OH, 1984.

R.C. Corlett:ASME J. Heat Transfer, 1966, vol. 88, pp. 376–82.

J.F. Ready:J. Appl. Phys., 1965, vol. 36, pp. 462–68.

J.G. Andrews and D.R. Atthey:J. Inst. Math. Appl., 1975, vol. 15, pp. 59–72.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, S.C., Wei, P.S. Energy-Beam redistribution and absorption in a drilling or welding cavity. Metall Trans B 23, 505–511 (1992). https://doi.org/10.1007/BF02649669

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02649669