Abstract

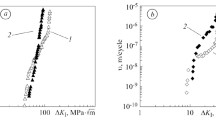

We present the results of the investigation of the growth of corrosion fatigue cracks in TBVK 140×11L drill pipes, determine quantitative characteristics of fatigue cracks in the pipes under stresses of different types as functions of the elapsed part of the entire service life, perform their statistical analysis, and propose a method for the prediction of the residual service life of these pipes.

Similar content being viewed by others

References

N. D. Shcherbuyk and N. V. Yakubovskii,Threaded Joints of Oil Pipes and Drilling Engines [in Russian], Nedra, Moscow (1974).

B. V. Kopei, “Investigation of corrosion fatigue crack growth rates in high-strength drill pipes,“Korroz. Zashch. Neftegaz. Promyshl., No. 1, 5–7 (1981).

L. A. Bashtannikov and B. V. Kopei,Design of a Drill String with Pipes Equally Reliable According to Their Fatigue Resistance [in Russian], VNIIÉGazprom, Moscow (1986).

I. G. Migal, B. V. Kopei, O. M. Karpash, et al., “Propagation of corrosion fatigue cracks in TBVK drill pipes,“Mash. Neftyan. Oborud., No. 9, 10–13 (1980).

N. A. Severinchik, O. T. Masnik, and B. V. Kopei,Corrosion and Corrosion Fatigue of Underground Drilling Equipment [in Russian], Vyshcha Shkola, L'viv (1981).

I. A. Peisakhova, V. A. Sutyrina, V. F. Shtamburg, et al., “Test bench for testing drili pipes for fatigue strength,”Mash. Neftyan. Oborud., No. 1, 11–14 (1965).

L. A. Bashtannlkov and B. V. Kopei,Reliability of Drill and Casing Pipes and Monitoring of the Quality of Their Materials [in Russian], VNIIÉGazprom, Moscow (1987).

V. I. Pokhmur'skyi, I. P., Gnyp, and V. V. Yaryts'kyi, “Evaluation of the period of crack initation on the basis of the energy criterion,”Fiz.-Khim. Mekh. Mater.,29, No. 4, 90–93 (1993).

I. P. Gnyp, I. S. Babyuk, and B. O. Chernov, “Optimization of the durability of threaded lock joints in a drill string on the basis of the criteria of fracture mechanics,”Fiz.-Khim. Mekh. Mater.,26, No. 4, 105–109 (1990).

Additional information

Ivano-Frankivs'k State Technical University of Petroleum and Gas, Ivano-Frankivs'k; Karpenko Physicomechanical Institute, Ukrainian Academy of Sciences, L'viv. Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 33, No. 1, pp. 103–106, January–February, 1997

Rights and permissions

About this article

Cite this article

Kopei, B.V., Gnyp, I.P. A method for the prediction of the service life of high-strength drill pipes based on the criteria of corrosion fatigue. Mater Sci 33, 99–103 (1997). https://doi.org/10.1007/BF02539133

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02539133