Abstract

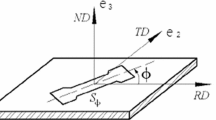

The on-line prediction of metal sheet formability requires that both material characterization (texture identification) and yield loci predetermination be done in very shor time intervals. Of two applicable approaches, i.e., continuum mechanics and crystallography-based methods, only the latter are suitable for this purpose. Several models of plasticity of a polycrystalline material were reviewed, and their applicability to the prediction of plastic anisotropy of face-centered cubic (FCC) metals was evaluated. A tailored set of cold-rolled copper alloy samples was designed and manufactured, representing the wide spectrum of textures and cold work levels typical for the sheet metal industry. The texture was quantitatively described in the form of the orientation distribution functions derived by the inversion of four incomplete pole figures. The Taylor-Bishop-Hill model was applied in order to calculate the planar variation of the plastic strain ratio. The continuum mechanics of textured polycrystals approach was also used for the prediction of the plastic strain-rate ratio for the same set of deformed materials. The theoretical predictions were compared with the plastic strain ratios measured in tensile tests using strain gauges. The applicability of the models for prediction of the plastic anisotropy of FCC metals was discussed in view of the operating deformation mechanisms and other factors such as strain hardening sensitivity and grain size/shape effects.

Similar content being viewed by others

References

H. J. Bunge,Texture Analysis in Materials Science (London: Butterworth & Co., 1982).

H. D. Merchant and D. J. Morris, eds.,Textures in Non-Ferrous Metals and Alloys (Warrendale, PA: TMS, 1985).

C. M. Sayers, Ultrasonic velocities in anisotropic polycrystalline aggregates,J. Appl. Phys. D: Appl. Phys. 15:2157 (1982).

C. M. Sayers, Angular dependent ultrasonic wave velocities in aggregates of hexagonal crystals,Ultrasonics 24:289 (1986).

R. B. Thompson, S. S. Lee, and J. F. Smith, Angular dependence of ultrasonic wave propagation in a stressed orthorhombic continuum: Theory and application to the measurement of stress and texture,J. Acoust. Soc. Am. 80(3):921 (1986).

R. B. Thompson, S. S. Lee, and J. F. Smith, Relative anisotropies of plane waves and guided modes in thin orthorhombic plates: Implication for texture characterization,Ultrasonics 25:133 (May 1987).

A. V. Clarket al., Texture monitoring in aluminum alloys: A comparison of ultrasonic and neutron and diffraction measurement,Ultrasonics 26:189 (July 1988).

M. Hirao, K. Aoki, and H. Fukuoka, Texture of polycrystalline metals characterized by ultrasonic velocity measurements,J. Acoust. Soc. Am. 81(5):1434 (May 1987).

M. Hirao, N. Hara, and H. Fukuoka, Ultrasonic monitoring of texture in cold-rolled steel sheets,J. Acoust. Soc. Am. 84(2):667 (Aug. 1988).

R. B. Thompson, J. F. Smith, S. S. Lee, and G. C. Johnson, A comparison of ultrasonic and X-ray determinations of texture in thin Cu and Al plates,Met. Trans. A.,20A:2431 (1989).

D. Danielet al., Acoustoelastic determination of the fourth order ODF coefficients and application toR-value prediction,Mater. Res. Soc. Symp. Proc. 142:77 (1989).

E. P. Papadakiset al., An automatic instrument for the ultrasonic measurement of texture,Proc. Fourth Int. Symp. Nondestructive Characterization of Materials, Annapolis, MD, June 11–14, 1990 (in press).

K. Kawashima, Nondestructive Measurement of Texture and Plastic Strain Ratio of Steel Sheets Using EMATs, ibid.

R. J. Roe, Description of crystallite orientation in polycrystalline materials. III. General solution to pole figure inversion,J. Appl. Phys.,36(6):2044 (1965).

H. J. Bunge, Zur darstellung allgemeiner texturen,Z. Metallkde 56:872 (1965).

H. J. Bunge,Mathematische Methoden der Texturanalyse (Akademie, Berlin, 1969).

H. J. Kopineck and H. Otten, Texture analyzer for on-liner m -value estimation,Textures Microstruct. 7:97 (1987).

H. J. Bunge, Prediction of anisotropy from orientation distribution functions,Textures in Non-Ferrous Metals and Alloys, H.D. Merchant and D.J. Morris, eds. (TMS, Warrendale, PA, 1985). p. 145.

W. G. Fricke and J. T. Ioannov, A practical texture measurement instrument,ICOTOM 8, J. S. Kallend and G. Gottstein, eds. (TMS, Warrendale, PA, 1988), p. 257.

J. Imhof, Determination of the orientation distribution function from one pole figure,Textures Microstruct.5:72 (1982).

J. A. Szpunar, P. Blandford, and D. C. Hinz, Calculation of the crystal orientation distribution function from synchroton radiation experimental data,J. Appl. Cryst. 22:559 (1989).

G. I. Taylor, Plastic strain in metals,J. Inst. Met. 62:307 (1938).

J. F. W. Bishop and R. Hill, A theory of the plastic distortion of a polycrystalline aggregate under combined stress,Phil. Mag. 42:414 (1951).

J. F. W. Bishop and R. Hill, A theoretical derivation of the plastic properties of a polycrystalline face-centered metal,Phil. Mag. 42:1298 (1951).

J. F. W. Bishop, A theoretical examination of the plastic deformation of crystals in solids,Phil. Mag. 44:51 (1953).

G. Y. Chin and W. L. Mammel, Generalization and equivalence of the minimum work (Taylor) and maximum work (Bishop-Hill) principles for crystal plasticity,Trans. Metall. Soc. AIME 245:1211 (June 1969).

J. Hirsch, and K. Lücke, Mechanism of deformation and development of rolling textures in polycrystalline FCC metals-Part I-III,Acta Metall. 36(11):2883 (1988).

H. Honneff and H. Mecking, A method for the determination of the active slip systems and orientation changes during single crystal deformation,Proc. ICOTOM 5 Aachen, G. Gottstein and K. Lücke, eds. (Springer, Berlin, 1978), p. 265.

P. Van Houtte,Mater. Sci. Eng. 55:69 (1982).

P. Van Houtte, Calculation of the yield locus of textured polycrystals using the Taylor and relaxed Taylor theory,Textures Microstruc. 7:29 (1987).

R. Fortunier and J. H. Driver, A continuous constraints model for large strain deformation,Acta Metall. 35(2):509 (1987).

R. Fortunier and J. H. Driver, Grain reorientations in rolled aluminum sheet: Comparison with prediction of continuous constraints model,Acta Metall. 35(6):1355 (1987).

R. Fortunier, J. H. Driver, J. Hirsch, and J. J. Jonas, Application of the continuous constraints model to the prediction of rolling textures,Eighth Int. Conf. on Textures of Materials (ICOTOM 8), J. S. Kallend and G. Gottstein, eds. (The Metallurgical Society, 1988), p. 319.

V. F. Kocks, A. S. Argon, and M. F. Ashby,Prog. Mater. Sci. 19 (1975).

G. Sachs,Z. d. Ver. Deut. Ing. 72:734 (1928).

E. Schmid,Proc. Int. Conf. Appl. Mech., Delft 342 (1924).

N. Kanetake, Y. Tozawa, and T. Otani, Calculations from texture of earing in deep drawing for FCC metal sheets,Int. J. Mech. Sci. 25(5):337 (1983).

N. Kanetake, Y. Tozawa, and S. Yamamoto, Calculations of earing in deep drawing for BCC metal sheets using texture data,Int. J. Mech. Sci. 27(4):249 (1985).

N. Kanetake and Y. Tozawa, Calculation of macroscopic deformation behavior using texture data for metal sheets,Eighth Int. Conf. on Textures of Materials (ICOTOM 8), J. S. Kallend and G. Gottstein, eds. (The Metallurgical Society, 1988), p. 1005.

J. Hirsch, R. Musick, and K. Lücke, eds. Comparison between earing,R-values and 3-dimensional orientation distribution functions of copper and brass sheets, ICOTOM 5, G. Gottstein and K. Lücke, eds. (Springer, Berlin, 1978), p. 437.

F. Montheillet, P. Gilormini, and J. J. Jonas, Relation between axial stresses and texture development during torsion testing: A simplified theory,Acta Metall. 33(4):705 (1985).

R. Hill, A theory of the yielding and plastic flow of anisotropic metals,Proc. R. Soc. Lond. A193:281 (1950).

PH. Lequeu, P. Gilormini, F. Montheillet, B. Bacroix, and J. J. Jonas, Yield surfaces for textured polycrystals—II. Analytical approach,Acta Metall. 35(950):1159 (1987).

PH. Lequeu, F. Montheillet, and J. J. Jonas, A simplified method for the prediction of plastic anisotropy in rolled sheet, inTextures in Non-Ferrous Alloys, H. D. Merchant and J. G. Morris, eds. (The Metallurgical Society, 1985), p. 189.

F. Montheillet, PH. Lequeu, P. Gilormini, and J. J. Jonas, A new method for describing the anisotropic properties of textured polycrystals,Eighth Int. Conf. on Textures of Materials (ICOTOM 8), J. S. Kallend and G. Gottstein, eds. (The Metallurgical Society, 1988), p. 1031.

ASTM Designation: E517-81 (Reapproved 1987), Standard Test Method for Plastic Strain Ratior for Sheet Metal.

W. Truskowski,Metall. Trans. 7A:327 (1976).

H. Hu,Metall. Trans. 6A:2307 (1976).

G. Jegaden, J. Voinecht, and P. Roquet,Mem. Sci. Rev. Metall. 59:273 (1962).

Y. C. Liu and L. K. Johnson, Hills plastic strain ratio of sheet metals,Metall. Trans. 16A:1531 (August 1985).

P. I. Welch and H. J. Bunge, Influence of grain size on plastic anisotropy in low-carbon steels,Materi. Sci. Technol. 2:354 (1988).

E. O. Hall,Proc. Phys. Soc. Lond. 643:747 (1951).

N. J. Petch,J. Iron Steel Inst. Lond. 173:25 (1953).

H. J. Bunge, Texture and directional properties of materials, inDirectional Properties of Materials (DGM Informationsgesellschaft mbH, Oberusel, 1988), p. 1.

A. D. Rollett, M. G. Stout, and U. F. Kocks,Polycrystal plasticity as applied to the problem of in-plane anisotropy in rolled cubic metals, in Advances in Plasticity, A. S. Khan and M. Tokuda, eds. (Pergamon Press, Oxford, 1990), p. 69.

F. Wagner, H. J. Bunge, and P. Van Houtte, in Influence of grain size and shape on texture formation and anisotropy coefficient,Eighth Int. Conf. on Textures of Materials (ICOTOM 8), J. S. Kallend and G. Gottstein, eds. (TMS, Warrendale, PA, 1988), p. 369.

C. S. Viana, J. S. Kallend, and G. J. Davies, The use of texture data to predict the yield locus of metal sheets,Int. J. Mech. Sci. 21:355 (1979).

O. Engler, J. Mizera, J. H. Driver, and K. Lücke, Texture and plastic anisotropy in model aluminum-lithium alloys,Proc. ICOTOM 9 (Avignon, France, 1990) (in press).

H. J. Bunge, Texture and directional properties of materials, inDirectional Properties of Materials, (DGM Informationsgesellschaft, Oberusel, 1988), p. 1.

H. Hu, Texture of metals,Texture 1:233 (1974).

H. Hu, P. R. Sperry, and P. A. Beck, Rolling textures in face-centered cubic metals,J. Met. 76 (Jan. 1952).

L. G. Schultz,J. Appl. Phys. 20:1030 (1945).

J. Hirsch, G. Burmeister, L. Hoenen, and K. Lücke, Autex III—A high speed texture goniometer and data processing system,Experimental Techniques of Texture Analysis, H. J. Bunge, ed. (Informationsgesellschaft, Oberusel, 1986), p. 63.

J. Pospiech and J. Jura, Determination of the orientation distribution function from incomplete pole figures,Z. Metallkde,65(4):324 (1974).

J. Hirsch, M. Loeck, L. Loof, and K. Lücke,Proc. ICOTOM 7 (Noordwijkerhout, 1984), p. 765.

J. Hirsch and K. Lücke, Texture analysis with the help of model functions, inTheoretical Methods of Texture Analysis, H. J. Bunge, ed., (DGM Informationsgesellschaft, Oberusel, 1987), p. 53.

C. J. Yu, Ph. D. thesis, The Pennsylvania State University, 1991.

K. J. Kozaczek, Ph. D. thesis, The Pennsylvania State University, 1991.

A. Kochendörfer,Reine und Angevandte Metalkunde (Springer, Berlin, 1941).

H. Bunge, M. Schultze, and D. Grzesik, Calculation of yield locus of polycrystalline materials according to the Taylor theory, inPeine + Saltzgitter Berichte, (Sonderheft, 1980).

T. Leffers, R. J. Asaro, J. H. Driver, and U. F. Kocks, Deformation textures: Simulation Principles Panel Report, inICOTOM 8, J. S. Kallend and G. Gottstein, eds. (TMS, Warrendale, Pennsylvania, 1988), p. 265.

K. Hashimoto and H. Margolin, The role of elastic interaction stresses on the onset of slip in polycrystalline alpha brass—I. Experimental determination of operating slip systems and qualitative analysis,Acta Metall. 31(5):773 (1983).

K. Hashimoto and H. Margolin, The role of elastic interaction stresses on the onset of slip in polycrystalline alpha brass—II. Rationalization of slip behavior,Acta Metall. 31(5):787 (1983).

Z. R. Wang and H. Margolin, Slip in a stress gradient: Multiple slip and cross slip in an alpha brass single crystal oriented for easy glide,Acta Metall. 32(6):977 (1984).

D. Juul Jensen and N. Hansen, Flow stress anisotropy in aluminum,Acta Metall. 38(8):1369 (1990).

T. Leffers and P. Van Houtte,Acta Metall. 37:1191 (1989).

T. Leffers and J. B. Bilde-Sørenson, Intra- and inter-granular heterogeneities in the plastic deformation of brass during rolling,Acta Metall. Mater. 38(10):1917 (1990).

H. E. Deve and R. J. Asaro, The development of plastic failure in crystalline materials: Shear bands in FCC polycrystals,Metall. Trans. A. 20A (April 1989).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kozaczek, K.J., Ruud, C.O., Hirsch, J. et al. Crystallography-based prediction of plastic anisotropy of polycrystalline materials. J Nondestruct Eval 12, 97–107 (1993). https://doi.org/10.1007/BF00565912

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00565912