Abstract

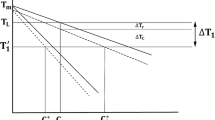

A critical part of the billet spray-forming process is the successive intermittent deposition of thin layers of semi-solid aluminium alloy at different points on the top surface of the billet. Each thin layer is made up of a large number of impacted semi-solid spray droplets. As successive layers of alloy are deposited significant re-melting and re-freezing of underlying layers can occur. If the layers become too dry, high porosity will result; if they are too wet, fluid dynamic surface instabilities are possible. In extreme cases no billet will form. The process is essentially incremental, so that heat fluxes within the deposit very close to the top surface play a major role in determining the final deposit microstructure.

In this paper transient heat transfer and solidification processes in the billet are analysed. First, some general features of billet heat transfer are discussed. The focus then narrows onto a thin layer of the deposit, lying very close to the billet surface. A boundary layer approximation is derived and computational results from this approximation are used to answer a number of questions of high practical value.

Similar content being viewed by others

References

R.H. Bricknell, The structure and properties of a nickel-base superalloy produced by Osprey atomisation-deposition, Met. Trans. 17A (1986) 583–591.

W. Kahl and J. Leupp, High performance aluminium produced by spray deposition, in proceedings of International Conference on Spray Forming, (1990) Swansea, U.K.

K.A. Kojima, R.E. Lewis and M.J. Kaufman, Microstructural characterization and mechanical properties of a spray-cast Al−Li−Cu−Mg−Zr alloy, in proceedings of Aluminium Lithium 5 Conference, (1992)

E.J. Lavernia and N.J. Grant, Structures and Properties of a Modified 7075 Aluminium Alloy Produced by Liquid Dynamic Compaction, International Journal of Rapid Solidification, 2 (1986) 93–106.

E.J. Lavernia, E. Gomez and N.J. Grant, The Structures and Properties of Mg-Al-Zr and Mg-Zn-Zr Alloy Produced by Liquid Dynamic Compaction, Materials Science and Engineering, 95 (1987) 225–236.

P.J. Meschter, J.K. Gregory, R.J. Lederich, J.E. O'Neal, E.J. Lavernia and N.J. Grant, Microstructures and properties of rapid solidification processed aluminium-high lithium alloys, Journal de Physique, 48-C3 (1987) 317–325.

K. Ogata, E.J. Lavernia, G. Rai and N.J. Grant, Structures and Properties of a Rapidly Solidified Superalloy Produced by Liquid Dynamic Compaction, International Journal of Rapid Solidification, 2 (1986) 21–35.

T.C. Willis, Spray deposition process for metal matrix composites manufacture, Powder Metallurgy, 31 (1988) 485–488.

A.J. Owen, Ultralite UL40-The World's lowest density commercially available aluminium alloy, Aluminium Industry, 12 (1993) 24–25.

S. Annavarapu, Spray casting of steel strip: Modelling and experimental studies, Ph.D. thesis, Drexel University, (1989).

S. Annavarapu, D. Apelian and A. Lawley Spray casting of steel strip: Process analysis, Met. Trans., 21A (1990) 3237–3255.

P.S. Grant, Spray forming of aluminium alloys, D.Phil. thesis, Oxford University, (1991).

E.M. Gutierrez, E.J. Lavernia, G.M. Trapaga and J. Szekely, A mathematical model of the Liquid Dynamic Compaction process. Part 2: Formation of the deposit, International Journal of Rapid Solidification, 4 (1988) 125–150.

E.M. Gutierrez, E.J. Lavernia, G.M. Trapaga, J. Szekely and N.J. Grant, A mathematical model of the spray deposition process, Met. Trans., 20A (1989) 71–85.

P. Mathur, Analysis of the spray deposition process, Ph.D. thesis, Drexel University, (1988).

P. Mathur, S. Annavarapu, D. Apelian and A. Lawley, Process control, modelling and applications of spray casting, Journal of Metals, 41 (1989) 23–28.

P. Mathur, D. Apelian and A. Lawley, Analysis of the spray deposition process, Acta Metall., 37 (1989), 429–443.

E.J. Lavernia, The evolution of microstructure during spray atomisation and deposition, International Journal of Rapid Solidification, 5 (1989), 47–85.

A.R.E. Singer and R.W. Evans, Incremental solidification and forming, Metals Technology, 10 (1983), 61–68.

P.W. Alexander, confidential report to Alcan-Oxford TCS grant GR/F/12006, February (1991).

K.P. Mingard, Alcan-Oxford TCS grant GR/F/12006, Metallurgical quality control reports, October (1990)-October (1992).

I.A. Frigaard, Mathematical modelling of an aluminium spray process, D.Phil. thesis, Oxford University, (1993).

I.A. Frigaard, The Dynamics of Spray-formed Billets, SIAM J. Appl. Math. 55(5) (1995) 1161–1203.

I.A. Frigaard, Growth Dynamics of Spray-formed Aluminium Billets, Part 1; Steady State Crown Shapes, Journal of Materials Processing and Manufacturing Science, 3 (1994) 173–193.

I.A. Frigaard, Growth Dynamics of Spray-formed Aluminium Billets, Part 2; Transient Billet Growth, Journal of Materials Processing and Manufacturing Science, 3 (1995) 257–275.

I.A. Frigaard and O. Scherzer, Growing the Perfect Billet, SIAM J. Appl. Math., accepted for publication.

P. Mathur, S. Annavarapu, D. Apelian and A. Lawley, Spray casting: an integral model for process understanding and control, Materials Science and Engineering, A 142 (1991) 261–276.

J. Madejski, Solidification of droplets on a cold surface. International Journal of Heat and Mass Transfer, 19 (1976) 1009–1013.

G.M. Trapaga and J. Szekely. Mathematical Modeling of the Isothermal Impingement of Liquid Droplets in Spraying Processes, Metall. Trans., 22B (1991) 901–914.

P.S. Grant and B. Cantor, Contract work for Alcan International Ltd., Banbury, U.K.; communication of 29th May, (1990).

P.C. Meek and J. Norbury, Two-stage, two-level finite difference schemes for non-linear parabolic equations. I.M.A. Journal on Numerical Analysis, 2 (1982) 335–356.

S. Rogers and L. Katgerman, Heat transfer and solidification of a stream of molten metal during atomisation by an impinging gas jet, Proceedings of the 5th International conference on numerical methods in thermal problems, Montreal, (1987), 1806–1817.

P.S. Grant, B. Cantor, S. Rogers and L. Katgerman, A computer model for droplet and particle trajectories and thermal profiles in spray forming, Cast Metals, 3 (1991) 227–232.

D.J. Sanders, Temperature beams produced by scanning Gaussian laser beams, Applied Optics, 23 (1) (1984) 30–35.

M.N. Yakunkin, Investigation of temperature fluctuations due to periodic heating by a laser pulse, Translated from Teplofizika Vysokikh Temperatur, 26(4) (1988) 759–766.

P. Ravi Vishnu, W.B. Li and K.E. Easterling, Heat flow model for pulsed welding, Materials Science and Technology, 7 (1991) 649–659.

I.Y. Smurov, A.A. Uglov, A.M. Lashyn, P. Matteazzi, L. Covelli and V. Tagliaferri, Modelling of pulseperiodic energy flow action on metallic materials. Int. J. Heat Mass Transfer, 34 (1991) 961–971.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Frigaard, I.A. Solidification of aluminium spray-formed billets. J Eng Math 30, 417–443 (1996). https://doi.org/10.1007/BF00049244

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00049244