Abstract

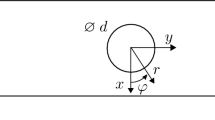

A stress intensity factor solution is developed for a large plate containing radial hole cracks loaded with arbitrary crack face pressure. When the pressure is defined as the unflawed hoop stress surrounding a mechanical fastener, stress intensity factor calibrations are readily computed by the linear superposition principle. Results obtained in this manner agree well with previous solutions determined for open holes loaded in remote tension. The potential usefulness of the present analysis is further demonstrated with application to specific fastener configurations, including interference fit fasteners, pin-loaded plates, and cold-worked holes.

Résumé

Une solution pour déterminer le facteur d'intensité des contraintes est développée dans le cas d'une grande plaque comportant des fissures émanant radialement d'un trou et sollicitées par une pression arbitraire agissant sur leurs faces. Lorsque la pression est définie comme valant la tension de membrane aux alentours d'un rivet et en l'absence de défauts, le factuer d'intensité des contraintes peut être directement calculé par le principe de superposition linéaire des effets. Les résultats obtenus suivant cette approche sont en bon accord avec les solutions précédemment développées pour des trous ouverts sollicités par des efforts de traction agissant à une certaine distance. L'utilité potentielle de l'analyse proposée est en outre démontrée dans le cas de son application à des configurations particulières de rivetage, telles que les rivets à coincement, les tôles sollicitées par des broches, et les trous écrouis par mandrinage.

Zusammenfassung

Man stellt eine Lösung für die Spannungsintensitätsfaktoren auf für den Fall einer großen Platte mit Rissen ausgehend von radialen Löchern mit beliebigen Druck am Rißausgang. Wenn der Druck als die Zylinder, die ein mechanisches Verbindungselement umgibt wenn kein Fehler vorhanden ist, definiert wird, dann kann man die Spannungsintensitätsfaktoren sofort nach dem Verfahren der linearen Überlagerung rechnen. Die so erhaltene Ergebnisse stimmen gut mit den früheren Lösungen für offene Löcher die durch Zugkräfte belastet sind, die in einiger Entfernung angebracht werden. Die große Nützlichkeit dieser Analyse wird weiterhin durch Anwendungen auf verschiedene Verbindungselemente, einschließlich Drucknieten, durch Spindeln belastete Platten und kaltgeformte Löcher, bewiesen.

Similar content being viewed by others

References

R. J. Gran, F. D. Orazio, P. C. Paris, G. R. Irwin and R. Hertzerg, Investigation and Analysis Development of Early Life Aircraft Structural Failures, Technical Report AFFDL-TR-70–149, Wright-Patterson Air Force Base, Ohio, March (1971).

C. F. Tiffany, R. P. Stewart and T. K. Moore, Fatigue and Stress-Corrosion Test of Selected Fasteners/Hole Processes, Technical Report ASD-TR-72–111, Wright-Patterson Air Force Base, Ohio, January (1973).

J. A. Regalbuto and O. E. Wheeler, Stress Distribution from Interference Fits and Uniaxial Tension, Experimental Mechanics, 10, 7 (1970) 274–280.

M. Allen and J. A. Ellis, Stress and Strain Distribution in the Vicinity of Interference Fit Fasteners, Technical Report AFFDL-TR-72–153, Wright-Patterson Air Force Base, Ohio, January (1973).

W. F. Adler and D. M. Dupree, Stress Analysis of Coldworked Fastener Holes, Technical Report AFML-TR-74–44, Wright Patterson Air Force Base, Ohio, March 1974.

J. H. CrewsJr., An Elastic Analysis of Stresses in a Uniaxially Loaded Sheet Containing an Interference-Fit Bolt, NASA Technical Note NASA TN D-6955, Langley Research Center, Hampton, Virginia, October 1972.

A. F. GrandtJr. and J. P. Gallagher, Procedures for Infinite Life Design of Mechanical Fasteners, Proceedings ofthe Air Force Systems Command 1973 Science and Engineering Symposium, AFSC TR-73–003, Vol. I, Kirtland Air Force Base, New Mexico, October (1973).

P. C. Paris, M. P. Gomez and W. E. Anderson, A Rational Analytic Theory of Fatigue, The Trend in Engineering, 13, 1, January (1961), University of Washington.

A. F. Emery, Stress-Intensity Factors for Thermal Stresses in Thick Hollow Cylinders, Journal of Basic Engineering, Transactions of the ASME, Series D, March (1966) 45–52.

A. F. Emery and G. E. Walker, Jr., Stress Intensity Factors for Edge Cracks in Rectangular Plates with Arbitrary Loadings, ASME Paper No. 68-WA/Met-18.

A. F. Emery, G. E. WalkerJr. and J. A. Williams, A Green's Function for the Stress Intensity Factors of Edge Cracks and Its Application to Thermal Stresses, Journal of Basic Engineering, Transactions of the ASME, Vol. 91, Series D, No. 4, December (1969) 618–624.

H. F. Bueckner, Weight Functions for the Notched Bar, Zeitschrift für Angewandte Mathematik und Mechanik, Vol. 51, pp 97–109, (1971).

J. H. CrewsJr. and N. H. White, Fatigue Crack Growth From a Circular Hole With and Without High Prior Loading, Technical Report NASA TN D-6899, Langley Research Center, Hampton, Virginia, September (1972).

R. A. Schmidt, An Approximate Technique for Obtaining Stress Intensity Factors for Some Difficult Planar Problems, paper presented at Fracture and Flaws Symposium, Albuquerque, New Mexico, March 2 (1973).

J. R. Rice, Some Remarks on Elastic Crack-Tip Stress Fields, International Journal of Solids and Structures, 8, 6 June (1972) 751–758.

O. L. Bowie, Analysis of an Infinite Plate Containing Radial Cracks Originating from the Boundary of an Internal Circular Hole, Journal of Mathematics and Physics, 35 (1956) 60–71.

P. C. Paris and G. C. Sih, Stress Analysis of Cracks, Fracture Toughness Testing and Its Applications, ASTM STP 381, American Society for Testing and Materials, (1965) 30–81.

Private correspondence with G. F. Zielsdorff, Air Force Flight Dynamics Laboratory, Wright Patterson Air Force Base, Ohio.

Private correspondence with H. Keck, United States Air Force Academy, Colorado Springs, Colorado.

S. Timoshenko and J. N. Goodier, Theory of Elasticity, McGraw-Hill Book Company (1951).

T. W. Orange, Crack Shapes and Stress Intensity Factors for Edge-Cracked Specimens, Stress Analysis and Growth of Cracks, Proceedings of the 1971 National Symposium on Fracture Mechanics, Part I, ASTM STP 513, American Society for Testing and Materials, (1972) 71–78.

D. J. Cartwright and G. A. Ratcliffe, Strain Energy Release Rate for Radial Cracks Emanating from a Pin Loaded Hole, International Journal of Fracture Mechanics, 8, 2, June (1972) 175–181.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Grandt, A.F. Stress intensity factors for some through-cracked fastener holes. Int J Fract 11, 283–294 (1975). https://doi.org/10.1007/BF00038895

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00038895