Abstract

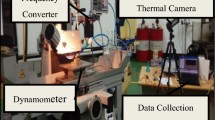

Grinding of any metallic materials are usually done under flood cooling using cutting fluid. However, excessive use of cutting fluid is not environmentally friendly. Researchers in the field are always looking for efficient as well as environmentally friendly grinding process for sustainable development. Minimum quantity lubrication with nanofluid is found to be one of the ways out. The main objective of this research is to identify the competitive effectiveness of MQL grinding over dry and flood cooling grinding. Graphite nanoparticles created from 2B pencil leads were mixed with ACCU-LUBE LB-3000 cutting fluid to prepare the nanofluid. Taguchi L9 Orthogonal Array was used to design the experiments. There were total of nine experiments, where three experiments were conducted under each of dry, flood-cooling and MQL with graphite-oil-based nanofluid conditions. Surface roughness and signal-to-noise ratios were analyzed. It was found that the condition during grinding is the largest contributor to surface roughness, contributing 54.82% of total, while depth of cut contributes 42.43% to the grinding process. Furthermore, grinding with MQL with graphite-oil-based nanofluid gives the lowest surface roughness value. After analyzing the S/N ratio and ANOVA, the optimum grinding condition is found to be MQL with graphite-oil-based nanofluid and 40 μm depth of cut.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Jamishidi H, Budak E (2018) Grinding temperature modelling based on time dependent heat source. Proc CIRP 77:299–302

Rifat M, Rahman MH, Das D (2017) A review on application of nanofluid MQL in machining. In: AIP conference proceedings, vol 1919. pp 020015

Zamiruddin N, Rosli N (2020) Application of minimum quantity lubrication for various machining process. J Modern Manuf Syst Technol 4:40–47

Shen B, Shih AJ, Tung SC (2008) Application of nanofluid in minimum quantity lubrication grinding. J Tribol Trans 51:730–737

Kananatahn J, Samykano M, Sudhakar K, Subramaniam SR, Selvani SK, Kumar NM, Keng NW, Kadirgama K, Hamzah WAW, Harun WSW (2018) Nanofluid as coolant for grinding process: an overview. In: IOP conference series materials science engineering, vol 342. pp 012078

Esarte J, Riehl RR, Mancin S, Blanco JM, Aresti M, Estella J (2021) Nanofluids as advanced cooling technology. In: Success stories. heat transfer-design, experimentation and applications, Intech Open, London

Kong L, Sun J, Bao Y (2017) Preparation, characterization and tribological mechanism of nanofluids. RSC Adv 7:12599–12609

Saifei W, Rahman MM, Yusoff AR, Radin MR (2020) Preparation, stability and wettability of nanofluid. J Mech Eng Sci 14(3):7244–7257

Sharma P, Sidhu BS, Sharma J (2015) Investigation of effects of nanofluids on turning of AISI D2 steel using minimum quantity lubrication. J Cleaner Prod 108:72–79

Khrisna PV (2019) Effectiveness of vegetable oil based nanofluids in machining of steel. J Multidisciplinary Stud 2(1):49–57

Kulkarni HB, Nadakatti MM, Kulkarni SC, Kulkarni RM (2020) Investigation on effect of nanofluid based minimum quantity lubrication technique for surface milling of A17075–T6 aerospace alloy. Mater Today: Proc 27:251–256

Mahadi MA, Choudhury IA, Azuddin M, Nukman Y (2017) Use of boric acid power aided vegetable oil lubricant in turning AISI 431 steel. Proc Eng 184:128–136

Vasu V, Kumar KM (2011) Analysis of nanofluids as cutting fluids in grinding EN-31 steel. Nano-Micro Lett 3:209–214

Virdi RL, Chatha SS, Singh H (2020) Performance evaluation of Inconel 718 under vegetable oils based nanofluids using minimum quantity lubrication grinding. Mater Today: Proc 33:1538–1545

Diabb J, Rodríguez CA, Mamidi N, Sandoval JA, Taha-Tijerina J, Martínez-Romero OO, Elías-Zúñiga A (2017) Study of lubrication and wear in single point incremental sheet forming (SPIF) process using vegetable oil nanolubricants. Wear 376:777–785

Sofiah GN, Samykano M, Pandey AK, Kadirgama K, Sharma K, Saidur R (2021) Immense impact from small particles: Review on stability and thermophysical properties of nanofluids. Sustain Energy Technol Assess 48:1011635

Minh DT, The LT, Bao NT (2017) Performance of Al2O3 nanofluids in minimum quantity lubrication in hard milling of 60Si2Mn steel using cemented carbide tools. Adv Mech Eng 9:1–9

Mohamad NB, Bahar R (2016) Minimum quantity lubrication (MQL) and its effect on tool wear during miniature drilling: an experimental study. Int J Eng Mater Manuf 1(2):65–70

Patil A, Raval J, Bangma T, Edinbarough I, Tai B, Stephenseon D, Suleiman O, Hung WN (2020) Characterization and performance of minimum quantity lubricants in through-tool drilling. Int J Eng Mater Manuf 5(4):98–115

Hossain S, Abedin MZ (2021) Effect of minimum quantity lubrication system for improving surface roughness in turning operation. Int J Eng Mater Manuf 6(1):50–59

Liao CA, Kwan YK, Chang TC, Fuh YK (2018) Ball-milled recycled lead-graphite in machining of steel. J Polym 10(7):799

Gupta MK, Sood PK, Sharma VS (2016) Machining parameters optimization of titanium alloy using response surface methodology and particle swarm optimization under minimum quantity lubrication. J Mater Manuf Process 31:1671–1682

Sivaiah P, Chakradhar D (2019) Modelling and optimization of sustainable manufacturing process in machining of 17–4 PH stainless steel. Measurement 134:142–152

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Rais, M.R.H., Ali, M.Y., Ramesh, S., Ya’akub, S.R., Ibrahim, Z. (2023). Performance of Graphite Based Nanofluid in MQL Grinding of Mild Steel. In: Maleque, M.A., Ahmad Azhar, A.Z., Sarifuddin, N., Syed Shaharuddin, S.I., Mohd Ali, A., Abdul Halim, N.F.H. (eds) Proceeding of 5th International Conference on Advances in Manufacturing and Materials Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-9509-5_47

Download citation

DOI: https://doi.org/10.1007/978-981-19-9509-5_47

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-9508-8

Online ISBN: 978-981-19-9509-5

eBook Packages: EngineeringEngineering (R0)