Abstract

Precipitation and coarsening kinetics of H-phase in Ni50Ti30Hf20 high-temperature shape-memory alloy and their effect on age hardening and transformation temperature behavior are discussed in the first part of this chapter. The critical size of H-phase precipitates responsible for breaking down the precipitate/matrix interface coherency, determined from experimental data, increases with increasing aging temperature. It is shown that transformation temperatures as well as transformation hysteresis can be controlled through the temperature and duration of aging. In the second part, the strain glass is discussed. Strain glass is a glassy phenomenon in shape-memory alloy systems, characterized by the frozen of martensitic nano-domains. It can be generated by doping sufficient defects into normal martensitic alloys and displays typical glassy features: invariability in average structure, dynamic freezing, broken ergodicity, and nano-domains. The strain glass can exhibits multiple functionalities such as new shape-memory effect and superelasticty due to the response of martensitic nano-domains to temperature and physical field. The third part is devoted to the elastocaloric effect in shape-memory alloys. Several criteria have been proposed that make it possible to predict a large elastocaloric effect during stress-induced martensitic transformation. Moreover, recent progress of advanced elastocaloric effect in additively manufactured, high-entropy, and other shape-memory alloys is also presented and discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Tong YX, Shuitcev AV, Zheng YF (2020) Adv Eng Mater 22:1900496

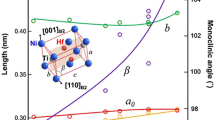

Shuitcev A, Vasin RN, Balagurov AM, Li L, Bobrikov IA, Sumnikov SV, Tong YX (2022) J Alloy Compd 899:163322

Shuitcev A, Vasin RN, Fan XM, Balagurov AM, Bobrikov IA, Li L, Golovin IS, Tong YX (2020) Scripta Mater 178:67–70

Karaca HE, Saghaian SM, Ded G, Tobe H, Basaran B, Maier HJ, Noebe RD, Chumlyakov YI (2013) Acta Mater 61:7422–7431

Stebner AP, Bigelow GS, Yang J, Shukla DP, Saghaian SM, Rogers R, Garg A, Karaca HE, Chumlyakov Y, Bhattacharya K, Noebe RD (2014) Acta Mater 76:40–53

Shuitcev A, Ren Y, Sun B, Markova GV, Li L, Tong YX, Zheng YF (2022) J Mater Sci Technol 114:90–101

Prasher M, Sen D, Bahadur J, Tewari R, Krishnan M (2019) J Alloy Compd 779:630–642

Santamarta R, Arroyave R, Pons J, Evirgen A, Karaman I, Karaca HE, Noebe RD (2013) Acta Mater 61:6191–6206

Yang F, Coughlin DR, Phillips PJ, Yang L, Devaraj A, Kovarik L, Noebe RD, Mills MJ (2013) Acta Mater 61:3335–3346

Moshref-Javadi M, Seyedein SH, Salehi MT, Aboutalebi MR (2013) Acta Mater 61:2583–2594

Meng XL, Cai W, Chen F, Zhao LC (2006) Scripta Mater 54:1599–1604

Kornegay SM, Kapoor M, Hornbuckle BC, Tweddle D, Weaver ML, Benafan O, Bigelow GB, Noebe RD, Thompson GB (2021) Mater Sci Eng, A 801:140401

Shuitcev A, Gunderov DV, Sun B, Li L, Valiev RZ, Tong YX (2020) J Mater Sci Technol 52:218–225

Evirgen A, Karaman I, Santamarta R, Pons J, Noebe RD (2015) Acta Mater 83:48–60

Yu TW, Gao YP, Casalena L, Anderson P, Mills M, Wang YZ (2021) Acta Mater 208:116651

Otsuka K, Wayman CM (1998) Shape memory materials. Cambridge University Press, Cambridge

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci 50:511

Sarkar S, Ren X, Otsuka K (2005) Evidence for strain glass in the ferroelastic-martensitic system Ti50−xNi50+x. Phys Rev Lett 95:205702

Wang Y, Ren X, Otsuka K (2008) Strain glass: glassy martensite. Mater Sci Forum 583:67

Wang D, Wang Y, Zhang Z et al (2010) Modeling abnormal strain states in ferroelastic systems: the role of point defects. Phys Rev Lett 105:205712

Wang Y, Huang CH, Wu HJ et al (2018) Premartensite serving as an intermediary state between strain glass and martensite in ferromagnetic Ni–Fe–Mn–Ga. Mater Des 152:102

Zhou Y, Xue D, Ding X et al (2009) High temperature strain glass in Ti50(Pd50-xCrx) alloy and the associated shape memory effect and superelasticity. Appl Phys Lett 95:151906

Wang Y, Zhou Y, Zhang J, Otsuka K et al (2010) Evolution of the relaxation spectrum during the strain glass transition of Ti48.5Ni51.5 alloy. Acta Mater 58, 4723

Wang D, Zhang Z, Zhang J et al (2010) Strain glass in Fe-doped Ti–Ni. Acta Mater 58:6206

Zhou Y, Xue D, Ding X et al (2010) Strain glass in doped Ti50(Ni50-xDx) (D=Co, Cr, Mn) alloys–Implication for the generality of strain glass in defect-containing ferroelastic systems. Acta Mater 58:5433

Wang Y, Ren X, Otsuka K et al (2007) Evidence for broken ergodicity in strain glass. Phys Rev B 76:132201

Tan Q, Li JF, Viehland D (2000) Role of potassium commodification on domain evolution and electrically induced strains in La modified lead zirconate titanate ferroelectric ceramics. J Appl Phys 88:3433

Karmakar S, Taran S, Chaudhuri BK et al (2006) Disorder-induced short-range ferromagnetism and cluster spin-glass state in sol-gel derived La0.7Ca0.3Mn1-xCdxO3(0≤x≤0.2). Phys Rev B 74:104407

Zhou YM, Xue DZ, Tian Y (2014) Direct evidence for local symmetry breaking during a strain glass transition. Phys Rev Lett 112:025701

Wang Y, Ren X, Otsuka K (2006) Shape memory effect and superelasticity in a strain glass alloy. Phys Rev Lett 97:225703

Wang Y, Ren X, Otsuka K et al (2008) Temperature-stress phase diagram of strain glass Ti48.5Ni51.5. Acta Mater 56:2885

Wang Y, Song X, Ding X et al (2011) Stress changed damping and associated transforming behavior in a Ti48.5Ni51.5 strain glass. Appl Phys Lett 99:051905

Wang Y, Gao J, Wu H et al (2014) Strain glass transition in a multifunctional β-type Ti alloy. Sci Rep 4:3995

Tang Z, Wang Y, Liao X et al (2015) Stress dependent transforming behaviors and associated functional properties of a nano-precipitates induced strain glass alloy. J Alloy Compd 622:622

Wang Y, Huang C, Gao J et al (2012) Evidence for ferromagnetic strain glass in Ni-Co-Mn-Ga Heusler alloy system. Appl Phys Lett 101:101913

Ren S, Xue D, Ji Y et al (2017) Low-field-triggered large magnetostriction in iron-palladium strain glass alloys. Phys Rev Lett 119:125701

Li B, Kawakita Y, Ohira-Kawamura S, Sugahara T, Wang H, Wang J, Chen Y, Kawaguchi SI, Kawaguchi S, Ohara K (2019) Colossal barocaloric effects in plastic crystals. Nature 567:506

Energy savings potential and RD&D opportunities for non-vapor-compression HVAC technologies, Report of the U.S. Dpt. of Energy, March 2014 https://energy.gov/eere/buildings/downloads/non-vapor-compression-hvac-technologies-report

Mischenko AS, Zhang Q, Scott JF, Whatmore RW, Mathur ND (2006) Giant electrocaloric effect in thin-film PbZr0.95Ti0.05O3. Science 311:1270–1271

Tishin AM, Spichkin YI (2014) Recent progress in magnetocaloric effect: mechanisms and potential applications. Int J Refrig 37:223–229

Bonnot E, Romero R, Mañosa L, Vives E, Planes A (2008) Elastocaloric effect associated with the martensitic transition in shape-memory alloys. Phys Rev Lett 100:125901

Mañosa L, González-Alonso D, Planes A, Bonnot E, Barrio M, Tamarit JL, Aksoy S, Acet M (2010) Giant solid-state barocaloric effect in the Ni-Mn-In magnetic shape-memory alloy. Nat Mater 9:478–481

Cui J, Wu Y, Muehlbauer J, Hwang Y, Radermacher R, Fackler S, Wuttig M, Takeuchi I (2012) Demonstration of high efficiency elastocaloric cooling with large ΔT using NiTi wires. Appl Phys Lett 101:073904

Mañosa L, Jarque-Farnos S, Vives E, Planes A (2013) Large temperature span and giant refrigerant capacity in elastocaloric Cu-Zn-Al shape memory alloys. Appl Phys Lett 103:211904

Kirsch S-M, Welsch F, Michaelis N, Schmidt M, Wieczorek A, Frenzel J, Eggeler G, Schütze A, Seelecke S (2018) NiTi-based elastocaloric cooling on the macroscale: from basic concepts to realization. Energy Technol 6:1567–1587

Yang Z, Cong DY, Sun XM, Nie ZH, Wang YD (2017) Enhanced cyclability of elastocaloric effect in boron-microalloyed Ni–Mn–In magnetic shape memory alloys. Acta Mater 127:33–42

Vives E, Burrows S, Edwards RS, Dixon S, Mañosa L, Planes A, Romero R (2011) Temperature contour maps at the strain-induced martensitic transition of a Cu–Zn–Al shape-memory single crystal. Appl Phys Lett 98:011902

Xiao F, Fukuda T, Kakeshita T, Jin X (2015) Elastocaloric effect by a weak first-order transformation associated with lattice softening in an Fe-31.2Pd (at.%) alloy. Acta Mater 87:8–14

Tušek J, Žerovnik A, Čebron M, Brojan M, Žužek B, Engelbrecht K, Cadelli A (2018) Elastocaloric effect vs fatigue life: exploring the durability limits of Ni–Ti plates under pre-strain conditions for elastocaloric cooling. Acta Mater 150:295–307

Qian S, Geng Y, Wang Y, Ling J, Hwang Y, Radermacher R, Takeuchi I, Cui J (2016) A review of elastocaloric cooling: materials, cycles and system integrations. Int J Refrig 64:1–19

Mañosa L, Planes A (2017) Materials with giant mechanocaloric effects: cooling by strength. Adv Mater 29:1603607

Chluba C, Ge W, de Miranda RL, Strobel J, Kienle L, Quandt E, Wuttig M (2015) Ultralow-fatigue shape memory alloy films. Science 348:1004–1007

Frenzel J, Wieczorek A, Opahle I, Maaß B, Drautz R, Eggeler G (2015) On the effect of alloy composition on martensite start temperatures and latent heats in Ni–Ti-based shape memory alloys. Acta Mater 90:213–231

Cong D, Xiong W, Planes A, Ren Y, Mañosa L, Cao P, Nie Z, Sun X, Yang Z, Hong X, Wang Y (2019) Colossal elastocaloric effect in ferroelastic Ni–Mn–Ti alloys. Phys Rev Lett 122:255703

Recarte V, Perez-Landazábal JI, Sánchez-Alarcos V, Zablotskii V, Cesari E, Kustov S (2012) Entropy change linked to the martensitic transformation in metamagnetic shape memory alloys. Acta Mater 60:3168–3175

Yang Z, Cong D, Yuan Y, Wu Y, Nie Z, Li R, Wang Y (2019) Ultrahigh cyclability of a large elastocaloric effect in multiferroic phase-transforming materials. Mater Res Lett 7:137–144

Cao Y, Zhou X, Cong D, Zheng H, Cao Y, Nie Z, Chen Z, Li S, Xu N, Gao Z, Cai W, Wang Y (2020) Large tunable elastocaloric effect in additively manufactured Ni–Ti shape memory alloys. Acta Mater 194:178–189

Li S, Cong D, Sun X, Zhang Y, Chen Z, Nie Z, Li R, Li F, Ren Y, Wang Y (2019) Wide-temperature-range perfect superelasticity and giant elastocaloric effect in a high entropy alloy. Mater Res Lett 7:482–489

Miracle DB, Senkov ON (2017) A critical review of high entropy alloys and related concepts. Acta Mater 122:448–511

Yang Z, Cong D, Yuan Y, Li R, Zheng H, Sun X, Nie Z, Ren Y, Wang Y (2020) Large room-temperature elastocaloric effect in a bulk polycrystalline Ni–Ti–Cu–Co alloy with low isothermal stress hysteresis. Appl Mater Today 21:100844

Acknowledgements

Yunxiang Tong acknowledges the financial support from the National Science Foundation of China (Grant Numbers 52050410340, 51971072). Yu Wang acknowledges the support from the National Natural Science Foundation of China (Grant Nos. 51931004, 51471127 and 91963111) and the Science and Technology Program of Yulin City (CXY-2020-049). Daoyong Cong acknowledges the financial support from the National Natural Science Foundation of China (Nos. 52031005, 51731005, and 52171172) and the Fundamental Research Funds for the Central Universities (Grant No. FRF-TP-18-008C1).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Shuitcev, A., Tong, Y., Wang, Y., Cong, D. (2022). Polycrystalline Shape-Memory Alloy and Strain Glass. In: Jiao, Z., Yang, T. (eds) Advanced Multicomponent Alloys. Materials Horizons: From Nature to Nanomaterials. Springer, Singapore. https://doi.org/10.1007/978-981-19-4743-8_12

Download citation

DOI: https://doi.org/10.1007/978-981-19-4743-8_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-4742-1

Online ISBN: 978-981-19-4743-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)