Abstract

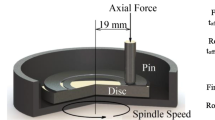

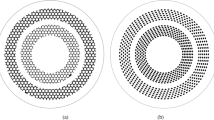

This paper presents the effect of the dimple size and dimple density on the wear properties of mild steel AISI 1060 surface under constant loading. The dimple surface texture is produced using a ball-end-nose milling tool on a cross-sectioned surface of 32.5 mm cylindrical sample with a CNC milling method. The samples acted as the pin for pin-on-disk apparatus with constant loading setup. The dimples size is between 1 mm to 4 mm. The wear size on samples are analyzed using 3D laser confocal microscopy image analysis technique. The result shows that the highest wear rate occurred at the samples with the smallest dimple diameter of 1 mm, while no significant of wear observed on samples with the largest dimple size of 4 mm. It is expected that dimple size has a significant effect onto the contact between pin and surface, as the effect of friction reduced with the reduction of contact size.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bin Zaki, M.I., Saptaji, K., Ramdan, R.D., Kurniawan, T.: Fabrication of micro dimples pattern using ball end mill. IOP Conf. Ser.: Mater. Sci. Eng. 547, 012009 (2019)

Cao, L., Chen, Y., Cui, J., Li, W., Lin, Z., Zhang, P.: Corrosion wear performance of pure Titanium Laser texturing surface by Nitrogen Ion Implantation. Metals 10(8), 990 (2020)

Park, G.C., Ko, T.J., Kurniawan, R., Ali, S.: Characterization of elliptical dimple fabricated with dual frequency vibration assisted machining. Korean Soc. Manuf. Process Eng. 20(2), 23–31 (2021)

Rosenkranz, A., Costa, H.L., Baykara, M.Z., Martini, A.: Synergetic effects of surface texturing and solid lubricants to tailor friction and wear – a review. Tribol. Int. 155, 106792 (2021)

Roy, T., Choudhury, D., Ghosh, S., Bin Mamat, A., Pingguan-Murphy, B.: Improved friction and wear performance of micro dimpled ceramic-on-ceramic interface for hip joint arthroplasty. Ceram. Int. 41(1), 681–690 (2015)

Zenebe Segu, D., Hwang, P.: Friction control by multi-shape textured surface under pin-on-disc test. Tribol. Int. 91, 111–117 (2015)

Wang, X., Wang, J., Zhang, B., Huang, W.: Design principles for the area density of dimple patterns. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 229(4), 538–546 (2015)

Acknowledgement

The authors would like to express gratitude and acknowledgement to University Malaysia Pahang, as the study is supported by Fundamental Research Grant (RDU1803128 and RDU182203-4).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ramli, M.R., Razak, N.A., Ismail, I., Jamaludin, A.S., Manaf, A.R.A. (2022). Effect of Dimple Size onto Wear Rate of Mild Steel AISI 1060 Surface. In: Abdollah, M.F.B., Amiruddin, H., Phuman Singh, A.S., Abdul Munir, F., Ibrahim, A. (eds) Proceedings of the 7th International Conference and Exhibition on Sustainable Energy and Advanced Materials (ICE-SEAM 2021), Melaka, Malaysia. ICE-SEAM 2021. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-3179-6_18

Download citation

DOI: https://doi.org/10.1007/978-981-19-3179-6_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-3178-9

Online ISBN: 978-981-19-3179-6

eBook Packages: EngineeringEngineering (R0)