Abstract

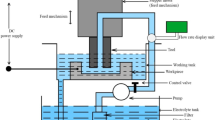

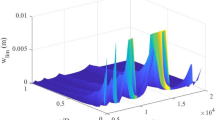

Manufacturing of micro complex profiles is a challenging task which is time consuming and expensive. The optimum parameter setting of machining process is essential to obtained desired profile on the workpiece with higher material removal rate. To achieve this purpose, a graphical user interface (GUI) is developed that associates metaheuristic technique, the firefly algorithm (FA). The developed GUI can be used effectively by the user for obtaining the optimal solution of non-traditional machining (NTM) processes. The GUI is tested on three NTM processes, namely electrochemical machining (ECM), electrochemical micro-machining (EMM), and electrochemical turning (ECT) and the results show the effectiveness of interface accompanying with the considered FA algorithm. The results for ECM, EMM, and ECT processes obtained using the considered metaheuristics techniques are compared with other algorithms, such as genetic algorithm (GA), artificial bee colony (ABC), and biogeography-based algorithm (BBO). It is observed that the value of MRR is improved by 12.3%, 78.7%, and 20.5% with respect to BBO algorithm in ECM, EMM, and ECT process, respectively. Similarly, the response value of surface characteristics like width overcut, linear overcut, surface roughness, and roundness error is reduced to negligible in the considered processes.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Rajurkar KP, Zhu D, Mcgeough JA, De Silva A (1999) New developments in electro-chemical machining. CIRP Ann Manuf Technol 48:567–579

Jain NK, Jain VK (2001) Modeling of material removal in mechanical type advanced machining processes: a state-of-art review. Int J Mach Tools Manuf 41:1573–1635

Bi ZM, Wang L (2012) Optimization of machining processes from the perspective of energy consumption: a case study. J Manuf Syst 31:420–428

Suriano S, Wang H, Hu SJ (2012) Sequential monitoring of surface spatial variation in automotive machining processes based on high definition metrology. J Manuf Syst 31:8–14

Jain NK, Jain VK (2007) Optimization of electro-chemical machining process parameters using genetic algorithms. Mach Sci Technol 11:235–258

Chakradhar D, Gopal AV (2011) Multi-objective optimization of electrochemical machining of EN31 steel by grey relational analysis. Int J Model Opt 1(2):113–117

Das S, Chakraborty S (2011) Selection of non-traditional machining processes using analytic network process. J Manuf Syst 30:41–53

Das MK, Kumar K, Barman T, Sahoo P (2014) Optimization of surface roughness and MRR in electrochemical machining of EN31 tool steel using grey-Taguchi approach. Procedia Mater Sci 6:729–740

Bhattacharyya B, Sorkhel SK (1998) Investigation for controlled electrochemical machining through response surface methodology-based approach. J Mater Process Technol 86:200–207

Schulze HP, Schatzing W (2013) Influences of different contaminations on the electro-erosive and the electrochemical micro-machining. Procedia CIRP 6:58–63

Senthilkumar C, Ganeshan G, Karthikeyan R (2011) Parametric optimization of electrochemical machining of Al/15% SiCp composites using NSGA-II. Trans Nonferrous Metals Soc 21:2294–2300

Hinduja S, Kunieda M (2013) Modelling of ECM and EDM processes. CIRP Ann Manuf Technol 62:775–797

Tang L, Yang S (2013) Experimental investigation on the electrochemical machining of 00Cr12Ni9Mo4Cu2 material and multi-objective parameters optimization. Int J Adv Manuf Technol 67:2909–2916

Ayyappan S, Sivakumar K (2015) Enhancing the performance of electrochemical machining of 20MnCr5 alloy steel optimization of process parameters by PSO-DF optimizer. Int J Adv Manuf Technol 82:2053–2064

Munda J, Bhattacharyya B (2006) Investigation into electrochemical micromachining (EMM) through response surface methodology based approach. Int J Adv Manuf Technol 35:821–832

Chae J, Park SS, Freihei T (2006) Investigation of micro-cutting operations. Int J Mach Tools Manuf 46:313–332

Dornfeld D, Min S, Takeuchi Y (2006) Recent advances in mechanical micromachining. CIRP Ann Manuf Technol 55:745–768

Samanta S, Chakraborty S (2011) Parametric optimization of some non-traditional machining processes using artificial bee colony algorithm. Eng Appl Artif Intell 24:946–957

He H, Zeng Y, Qu N (2015) An investigation into wire electrochemical micro machining of pure tungsten. Precis Eng 45:285–291

Goud M, Sharma AK, Jawalkar C (2015) A review on material removal mechanism in electrochemical discharge machining (ECDM) possibilities to enhance the material removal rate. Precis Eng 45:1–17

Hajian M, Razfar MR, Movahed S (2016) An experimental study on the effect of magnetic field orientations and electrolyte concentrations on ECDM milling performance of glass. Precis Eng 45:322–331

Kao PS, Hocheng H (2003) Optimization of electrochemical polishing of stainless steel by grey relational analysis. J Mater Process Technol 140:255–259

Fister I, Yang XS, Brest JA (2013) Comprehensive review of firefly algorithms. Swarm Evol Comput 13:34–46

Gandomi AH, Yang X, Talatahari S, Alavi AH (2013) Firefly algorithm with chaos. Commun Nonlinear Sci Numer Simul 18:89–98

Zaki EM, El-sawy AA (2013) Hybridizing ant colony optimization with firefly algorithm for unconstrained optimization problems. Appl Math Comput 224:473–483

Mukherjee R, Chakraborty S (2013) Selection of the optimal electrochemical machining process parameters using biogeography-based optimization algorithm. Int J Adv Manuf Technol 64:781–791

El-Taweel TA, Gouda SA (2011) Performance analysis of wire electrochemical turning process—RSM approach. Int J Adv Manuf Technol 53:181–190

Malapati M, Bhattacharyya B (2011) Investigation into electrochemical micromachining process during micro-channel generation. Mater Manuf Process 26:1019–1027

Yang XS (2008) Nature-inspired metaheuristics algorithm, 2nd edn. Luniver Press, UK

Singh D, Shukla RS (2016) Optimisation of electrochemical micromachining and electrochemical discharge machining process parameters using firefly algorithm. Int J Mech Manuf Sys 9(2):137–159

Shukla RS, Singh D (2017) Selection of parameters for advanced machining processes using firefly algorithm. Eng Sci Technol Int J 20(1):212–221

Chapman SJ (2008) Matab® programming for engineers. Thomson Asia Ltd, Singapore

Hahn BH, Valentine DT (2010) Essential Matlab for engineers and scientist. Elsevier Academic Press, Cambridge

Tapie L, Mawussi B, Bernard A (2012) Topological model for machining of parts with complex shapes. Comput Ind 63:528–541

Arezoo B, Ridgway K, Al-Ahmari AMA (2000) Selection of cutting tools and conditions of machining operations using an expert system. Comput Ind 42:43–58

Kumar R, Rajan A, Talukdar FA, Dey N, Santhi V, Balas VE (2017) Optimization of 5.5-GHz CMOS LNA parameters using firefly algorithm. Neural Comput Appl 28(12):3765–3779

Jagatheesan K, Anand B, Samanta S, Dey N, Ashour AS, Balas VE (2017) Design of a proportional-integral-derivative controller for an automatic generation control of multi-area power thermal systems using firefly algorithm. IEEE/CAA J Automatica Sin 6(2):503–515

Li J, Li T, Yu Y, Zhang Z, Pardalos PM, Zhang Y (2019) Discrete firefly algorithm with compound neighborhoods for asymmetric multi-depot vehicle routing problem in the maintenance of farm machinery. Appl Soft Comput J 81:105–119

Kumar A, Konar A, Bhattacharjee T, Das S (2018) Synergism of firefly algorithm and Q-learning for robot arm path planning. Swarm Evol Comput 43:50–68

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Singh, D., Shukla, R.S. (2020). Development of Firefly Algorithm Interface for Parameter Optimization of Electrochemical-Based Machining Processes. In: Dey, N. (eds) Applications of Firefly Algorithm and its Variants. Springer Tracts in Nature-Inspired Computing. Springer, Singapore. https://doi.org/10.1007/978-981-15-0306-1_2

Download citation

DOI: https://doi.org/10.1007/978-981-15-0306-1_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0305-4

Online ISBN: 978-981-15-0306-1

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)