Abstract

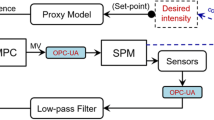

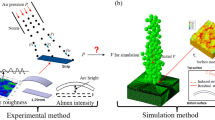

Peening velocity (shot velocity) is one of the key parameters in shot peening process, which directly relates to intensity and coverage area. A desired intensity and/or coverage area can be attained by controlling the peening velocity to the right value. However, this is a challenging task as the peening velocity is the function of many different variables (peening system, nozzle design, air pressure, media (shot) flow rate, shot size, etc.). In this study, we develop a process model that links the input/operating parameters of the peening machine to the average shot stream velocity upon impact. In particular, the formulation of shot stream velocity is derived as the function of input air pressure and media flow rate, which also accounted for the peening system and nature of the flow inside (e.g., nozzle shape, pressure loss, energy transfer, and turbulence, etc.). The model is validated against the experimental data for different inlet pressure as well as the media flow rates. The calculated results are in good agreement with experimental data. Furthermore, the model validity and reliability are examined for the wide range of input parameters and the system parameter. The results also indicated that the developed process model can be applied for different peening machines with different nozzle design by defining relevant model constants. There are a few key applications for the process model; which are (1) the model can support the operators to rapidly estimate and setup the working conditions of the machine to attain the desired peening intensity and coverage area to avoid the cost and time in doing experiments based on trials and errors, and (2) The model also can be used in model predictive control (MPC) to develop the controller for the peening machine.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Harrison, J.: Controlled shot-peening: cold working to improve fatigue strength. Heat Treat. 19, 16–18 (1987)

David, K.: Quantification of shot peening coverage. The Shot Peener, Fall (2014). https://www.electronics-inc.com/wp-content/uploads/QuantificationOfShotPeeningCoverage.pdf

Nguyen, V.B., Poh, H.J., Zhang, Y.W.: Predicting shot peening coverage using multi-phase computational fluid dynamics simulations. Powder Technol. 256, 100–112 (2014). https://doi.org/10.1016/j.powtec.2014.01.097

David, K.: Variability of a shot stream’s measured peening intensity. The Shot Peener, Summer (2011). https://www.shotpeener.com/library/pdf/2011120.pdf

David, K.: Peening intensity: true meaning and measurement Strategy. The Shot Peener, Summer (2016). https://www.shotpeener.com/library/detail.php?anc=2016030

David, K.: Curve fitting for shot peening data analysis. The Shot Peener, 6. Spring (2002). https://www.shotpeener.com/library/pdf/2002091.pdf

David, K., Abyaneh, M.Y.: Theoretical basis of shot peening coverage control. Shot Peener, vol. 13, no. 3, pp. 5–70 (1999). https://www.shotpeener.com/library/pdf/1995043.pdf

David, K.: Theoretical principal of shot peening coverage. Shot Peener, vol. 19, no. 2, pp. 24–26 (2005). https://www.shotpeener.com/library/detail.php?anc=2005145

Bill, B., Kevin, Y.: Particle velocity sensor for improving shot peening process control. Shot Peener, Technological aspects (2005). https://www.shotpeener.com/library/pdf/2005114.pdf

Brunton, S.L., Joshua, L.P., Kutz J.N.: Discovering governing equations from data by sparse identification of nonlinear dynamical systems. In: Proceedings of the National Academy of Sciences of the United States of America, vol. 113, no. 15, pp. 3932–3937 (2016). https://doi.org/10.1073/pnas.1517384113

Tobias, G.: Model Predictive Control of High Power Converters and Industrial Drives. Wiley, London (2016). ISBN 978-1-119-01090-6

Wang, L.: Model Predictive Control System Design and Implementation Using MATLAB®, p. xii. Springer Science & Business Media, London (2009)

Kaiser, E., Kutz, J.N., Brunton, S.L.: Sparse identification of nonlinear dynamics for model predictive control in the low-data limit, 474. In: Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences. https://doi.org/10.1098/rspa.2018.0335

Zhang, L., Schaeffer H.: On the convergence of the SINDy algorithm. Journal CoRR (2018). http://arxiv.org/abs/1805.06445

Acknowledgment

This work is supported by the project entitled: “Machine Learning Assisted Control of Shot Peening Process” under Grant number A1894a0032, which is lead by Dr. Kang Chang Wei (IHPC, A*STAR) and Dr. Ampara (ARTC, A*STAR).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Van Bo, N., Te, B., Teo, A., Ahluwalia, K., Aramcharoen, A., Chang Wei, K. (2020). Process Model for Evaluating the Peen Velocity in Shot Peening Machine. In: Itoh, S., Shukla, S. (eds) Advanced Surface Enhancement. INCASE 2019. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-0054-1_4

Download citation

DOI: https://doi.org/10.1007/978-981-15-0054-1_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0053-4

Online ISBN: 978-981-15-0054-1

eBook Packages: EngineeringEngineering (R0)