Abstract

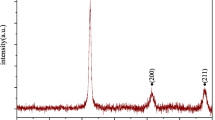

This present study focuses on the surface integrity characteristics of the machined NiTiHf high temperature shape memory alloys. The NiTiHf specimens were machined under dry, minimum quantity lubrication (MQL) and cryogenic cooling at two different cutting speeds. Experimental data on microhardness, latent heat and phase transformation temperature is presented and analyzed to evaluate the surface and subsurface characteristics of the machined NiTiHf specimens. It is found that machining process particularly cryogenic machining alters microhardness, latent heat and phase transformation temperature of Ni-rich NiTiHf alloy. This study demonstrates that cryogenic machining process leads to occurring strain hardened layer on the surface and subsurface of machined workpiece. Phase transformation response including transformation temperature and latent heat for transformation of this affected layer shows significant difference comparing with the bulk of the workpiece. This difference is evidently observed from the cryogenically machined specimens than the specimens machined under dry and MQL conditions.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ma, J., Karaman, I., Noebe, R.D.: High temperature shape memory alloys. Int. Mater. Rev. 55, 257–315 (2010)

Jani, J.M., Leary, M., Subic, A., Gibson, M.A.: A review of shape memory alloy research, applications and opportunities. Mater. Des. 56, 1078–1113 (2014)

Hayrettin, C., Karakoc, O., Karaman, I., Mabe, J., Santamarta, R., Pons, J.: Two way shape memory effect in NiTiHf high temperature shape memory alloy tubes. Acta Mater. 163, 1–13 (2019)

Evirgen, A., Karaman, I., Santamarta, R., Pons, J., Noebe, R.: Microstructural characterization and superelastic response of a Ni50. 3Ti29. 7Zr20 high-temperature shape memory alloy. Scr. Mater. 81, 12–15 (2014)

Benafan, O., Garg, A., Noebe, R., Bigelow, G., Padula li, S., Gaydosh, D., Schell, N., Mabe, J., Vaidyanathan, R.: Mechanical and functional behavior of a Ni-rich Ni 50.3 Ti29.7 Hf20 high temperature shape memory alloy. Intermetallics 50, 94–107 (2014)

Benafan, O., Brown, J., Calkins, F.T., Kumar, P., Stebner, A., Turner, T., Vaidyanathan, R., Webster, J., Young, M.L.: Shape memory alloy actuator design: CASMART collaborative best practices. In: ASME 2011 Conference on Smart Materials, pp. 18–21 (2011)

Kaynak, Y., Karaca, H.E., Noebe, R.D., Jawahir, I.S.: The effect of active phase of the work material on machining performance of a NiTi shape memory alloy. Metall. Mater. Trans. A 46, 2625–2636 (2015)

Jawahir, I.S., Brinksmeier, E., M’Saoubi, R., Aspinwall, D.K., Quteiro, J.C., Meyer, D., Umbrello, D., Jayal, A.D.: Surface integrity in material removal processes: Recent advances. CIRP Ann. Manuf. Technol. 60, 603–626 (2011)

Kaynak, Y., Karaca, H., Jawahir, I.: Cutting speed dependent microstructure and transformation behavior of NiTi alloy in dry and cryogenic machining. J. Mater. Eng. Perform. 24, 452–460 (2015)

Kirmacioglu, K.E., Kaynak, Y., Benafan, O.: Machinability of Ni-rich NiTiHf high temperature shape memory alloy. Smart Mater. Struct. 28, 055008 (2019)

Oxley, P.: Mechanics of Machining. Ellis Horwood, Chichester (1989)

De la Flor, S., Urbina, C., Ferrando, F.: Effect of mechanical cycling on stabilizing the transformation behaviour of NiTi shape memory alloys. J. Alloy. Compd. 469, 343–349 (2009)

Miller, D.A., Lagoudas, D.C.: Thermomechanical characterization of NiTiCu and NiTi SMA actuators: influence of plastic strains. Smart Mater. Struct. 9, 640–652 (2000)

Acknowledgments

Financial support from TUBITAK (The scientific and Technological Research Council of Turkey) under Project number 116M346 is greatly acknowledged. OB acknowledges support and funding from the NASA Aeronautics Research Mission Directorate (ARMD) Transformational Tools & Technologies (TTT) project.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Kaynak, Y., Tascioglu, E., Benafan, O. (2020). Surface Integrity Characteristics of NiTiHf High Temperature Shape Memory Alloys. In: Itoh, S., Shukla, S. (eds) Advanced Surface Enhancement. INCASE 2019. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-0054-1_26

Download citation

DOI: https://doi.org/10.1007/978-981-15-0054-1_26

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0053-4

Online ISBN: 978-981-15-0054-1

eBook Packages: EngineeringEngineering (R0)