Abstract

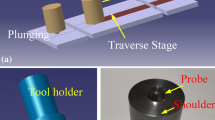

The tool offset parameter’s influence on joint strength of friction stir welding (FSW) of aluminum alloy 6061 and S235JR steel performed on a conventional belting milling machine was evaluated. The type of welding defects that arose at different tool offset values and how they affect the ultimate tensile strength (UTS) of the joints produced are also studied. It was found that at +0.2 and 0 mm offset, welding was incomplete and tunnel defects were formed, with average tensile strengths of 22.91 and 41.62 MPa for joints welded at each tool offset values respectively. Tool offset value of −0.2 mm was found to produce the best joints in terms of tensile strength, at an average of 95.73 MPa. For all joints, in terms of defects it was found that incomplete welding severely reduced tensile strength of joints, while tunnel defects also deteriorated tensile strength of joints albeit to a lesser degree.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Thomas W (1991) Friction stir butt welding. International Patent Application No. PCT/G892/0220

Tsujino J, Hidai K, Hasegawa A et al (2002) Ultrasonic butt welding of aluminum, aluminum alloy and stainless steel plate specimens. Ultrasonics 40:371–374

Yamamoto N, Takahashi M, Aritoshi M, Ikeuchi K (2005) Effect of interfacial layer on bond strength of friction-welded interface of Al-Mg5083 alloy to mild steel. Q J Jpn Weld Soc 23:496–503. doi:10.2207/qjjws.23.496

Kuroda S, Saida K, Nishimoto K (1999) Microstructures and properties of directly joint of A6061 aluminum alloy and SUS316 stainless steel. Q J Jpn Weld Soc 17–3:484–489

Kimapong K, Watanabe T (2005) Lap joint of A5083 aluminum alloy and SS400 steel by friction stir welding. Mater Trans 46:835–841

Fratini L, Buffa G, Filice L, Gagliardi F (2006) Friction stir welding of AA6082-T6 T-joints: process engineering and performance measurement. Proc Inst Mech Eng Part B J Eng Manuf 220:669–676. doi:10.1243/09544054JEM327

Kusuda Y (2013) Feature article Honda develops robotized FSW technology to weld steel and aluminum and applied it to a mass-production vehicle. Ind Robot Int J 40:208–212. doi:10.1108/01439911311309889

Kimapong K, Watanabe T (2004) Friction stir welding of aluminum alloy to steel. Weld J 83:277–282

Chen CM, Kovacevic R (2004) Joining of Al 6061 alloy to AISI 1018 steel by combined effects of fusion and solid state welding. Int J Mach Tools Manuf 44:1205–1214. doi:10.1016/j.ijmachtools.2004.03.011

Ramachandran KK, Murugan N, Kumar SS (2015) Effect of tool axis offset and geometry of tool pin profile on the characteristics of friction stir welded dissimilar joints of aluminum alloy AA5052 and HSLA steel. Mater Sci Eng A 639:219–233. doi:10.1016/j.msea.2015.04.089

Karimi N, Nourouzi S, Shakeri M et al (2012) Effect of tool material and offset on friction stir welding of Al alloy to carbon steel. Adv Mater Res 445:747–752. doi:10.4028/www.scientific.net/AMR.445.747

Hasil Karya (2014) MASTIKA B-3HS milling machine catalogue http://www.hasilkarya.com.my/ecatalog/MILLING-MACHINE/3HP-Milling/B3.pdf

ASTM International (2009) Standard test methods for tension testing of metallic materials 1. Astm 1–27. doi:10.1520/E0008

SHIMADZU (Shimadzu Corporation) (2016) Universal testing/tensile testing machine: SHIMADZU (Shimadzu Corporation). http://shimadzu.com/an/test/universal/index.html

Asadi P, Akbari M, Karimi-Nemch H (2014) 12—Simulation of friction stir welding and processing. In: Givi MKB, Asadi P (eds) Advances in friction stir welding processing. Woodhead Publishing, p 511

Kundu S, Roy D, Bhola R et al (2013) Microstructure and tensile strength of friction stir welded joints between interstitial free steel and commercially pure aluminium. Mater Des 50:370–375. doi:10.1016/j.matdes.2013.02.017

Chen TP, Lin W-B (2010) Optimal FSW process parameters for interface and welded zone toughness of dissimilar aluminium–steel joint. Sci Technol Weld Join 15:279–285. doi:10.1179/136217109X12518083193711

Uzun H, Dalle Donne C, Argagnotto A et al (2005) Friction stir welding of dissimilar Al 6013-T4 to X5CrNi18-10 stainless steel. Mater Des 26:41–46. doi:10.1016/j.matdes.2004.04.002

Krasnowski K, Hamilton C, Dymek S (2015) Influence of the tool shape and weld configuration on microstructure and mechanical properties of the Al 6082 alloy FSW joints. Arch Civ Mech Eng 15:133–141. doi:10.1016/j.acme.2014.02.001

Sato YS, Urata M, Kokawa H, Ikeda K (2003) Hall-Petch relationship in friction stir welds of equal channel angular-pressed aluminium alloys. Mater Sci Eng A 354:298–305. doi:10.1016/S0921-5093(03)00008-X

Threadgill PL, Leonard AJ, Shercliff HR, Withers PJ (2009) Friction stir welding of aluminium alloys. Int Mater Rev 54:49–93. doi:10.1179/174328009X411136

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50:1–78. doi:10.1016/j.mser.2005.07.001

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Syafiq, W.M., Afendi, M., Daud, R., Mazlee, M.N., Jaafar, N.A. (2017). Variation of Tool Offsets and Its Influence on Mechanical Properties of Dissimilar Friction Stir Welding of Aluminum Alloy 6061 and S235JR Mild Steel by Conventional Belting Milling Machine. In: Awang, M. (eds) 2nd International Conference on Mechanical, Manufacturing and Process Plant Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-4232-4_3

Download citation

DOI: https://doi.org/10.1007/978-981-10-4232-4_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-4231-7

Online ISBN: 978-981-10-4232-4

eBook Packages: EngineeringEngineering (R0)