Abstract

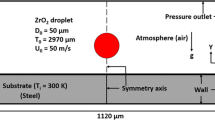

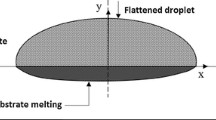

Most of the studies reported for droplet impact and spreading on a substrate in a thermal spray coating process assume that droplet material solidifies as a pure substance, i.e., phase change occurs at a fixed temperature. The alloy-type behavior of the droplet impact where it solidifies within liquidus and solidus temperature is not well reported. The role of formation of mushy zone and species composition variation during the coating layer formation while using a multi-constituent alloy material is not established. This work investigates the spreading and solidification characteristics of an alloy droplet impacting on a substrate. Two-dimensional axisymmetric model has been used to simulate the transient flow and alloy solidification dynamics during the droplet impingement process. Volume of fluid (VOF) surface tracking method coupled with the alloy solidification model within a one-domain continuum formulation is developed to describe the transport phenomena during the droplet impact, spreading, and solidification of an alloy droplet on a flat substrate. Using the model, the characteristics of alloy solidification in coating formation are highlighted.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- c :

-

Specific heat capacity (m2 s−2 K−1)

- C :

-

Solute concentration (kg kg−1)

- D :

-

Solute mass diffusivity (m2 s−1)

- D o :

-

Initial droplet diameter (mm)

- f l :

-

Weight fraction of liquid (kg kg−1)

- f s :

-

Weight fraction of solid (kg kg−1)

- F :

-

Volume of fluid function

- F vol :

-

Continuum surface tension force source term (N m−3)

- \(\vec{g}_{r}\) :

-

Acceleration due to gravity vector (m s−2)

- k :

-

Thermal conductivity (W m−1 K−1)

- k p :

-

Equilibrium partition coefficient

- K :

-

Permeability of mushy zone (m2)

- L :

-

Latent heat of fusion (J kg−1)

- m L :

-

Liquidus slope (°C wt%−1)

- p :

-

Pressure (N m−2)

- t :

-

Time (s)

- T :

-

Temperature (K)

- T m :

-

Melting point of pure substance (K)

- \(\vec{u}\) :

-

Continuum velocity vector (m s−1)

- U 0 :

-

Initial droplet velocity (m s−1)

- ρ :

-

Density (kg m−3)

- μ :

-

Dynamic viscosity (kg m−1 s−1)

- d:

-

Droplet

- subs:

-

Substrate

- air:

-

Air

- alloy:

-

Alloy

- eff:

-

Effective

- l:

-

Liquid

- s:

-

Solid

- 0:

-

Initial

References

Ahmed AM, Rangel RH (2002) Metal droplet deposition on non-flat surfaces: effect of substrate morphology. Int J Heat Mass Transf 45:1077–1091

Attinger D, Poulikakos D (2001) Melting and resolidification of a substrate caused by molten micro droplet impact. ASME J Heat Transf 123:1110–1122

Aziz SD, Chandra S (2000) Impact, recoil and splashing of molten metal droplets. Int J Heat Mass Transf 43:2841–2857

Bellet M, Combeau H, Fautrelle Y, Gobin D, Rady M, Arquis E, Budenkova O, Dussoubs B, Duterrail Y, Kumar A, Gandin CA, Goyeau B, Mosbah S, Zaloznik M et al (2009) Call for contributions to a numerical benchmark problem for 2D columnar solidification of binary alloys. Int J Therm Sci 48:2013–2016

Bennett T, Poulikakos D (1994) Heat transfer aspects of Splat-Quench solidification: modeling and experiment. J Mater Sci 29:2025–2039

Bussmann M, Chandra S, Mostaghimi J et al (2000) Modeling the splash of a droplet impacting a solid surface. Phys Fluids 12:3121–3132

Chandra S, Fauchais P (2009) Formation of solid splats during thermal spray deposition. J Therm Spray Technol 18:148–180

Fukumoto M, Huang Y (1999) Flattening mechanism in thermal sprayed Ni particles impinging on flat substrate surface. J Therm Spray Technol 8(3):427–432

Fukumoto M, Yang K, Tanaka K, Usami T, Yasui T, Yamada M et al (2011) Effect of substrate temperature and ambient pressure on heat transfer at interface between molten droplet and substrate surface. J Therm Spray Technol 20:48–58

Hong FJ, Qiu HH (2005) Modeling of substrate remelting, flow, and resolidification in microcasting. Numer Heat Transfer, Part A 48:987–1008

Inada S, Yang WJ (1994) Solidification of molten metal droplets impinging on a cold surface. Exp Heat Transfer 7:93–100

Kamnis S, Gu S (2005) Numerical modelling of droplet impingement. J Phys D Appl Phys 38:3664–3673

Kamnis S, Gu S, Lu TJ, Chen C et al (2008) Numerical modelling of sequential droplet impingements. J Phys D Appl Phys 41:165303 (7 pp)

Kang B, Zhao Z, Poulikakos D et al (1994) Solidification of liquid metal droplets impacting sequentially on a solid surface. ASME J Heat Transfer 116:436–445

Kumar A, Gu S, Tabbara H, Kamnis S et al (2012a) Study of impingement of hollow ZrO2 droplets onto a substrate. Surf Coat Technol 220:164–169

Kumar A, Gu S, Kamnis S et al (2012b) Simulation of impact of a hollow droplet on a flat surface. Appl Phys A Mater Sci Process 109:101–109

Li L, Wang XY, Wei G, Vaida A, Zhang H, Sampath S et al (2004) Substrate melting during thermal spray splat quenching. Thin Solid Films 468:113–119

Liu H, Lavernia EJ, Rangel RH et al (1993) Numerical simulation of substrate impact and freezing of droplets in plasma spray processes. J Phys D Appl Phys 26:1900–1908

Madejski J (1976) Solidification of droplets on a cold surface. Int J Heat Mass Transf 19:1009–1013

Rangel RH, Bian X (1997) Metal-droplet deposition model including liquid deformation and substrate remelting. Int J Heat Mass Transf 40:2549–2564

Shakeri S, Chandra S (2002) Splashing of molten tin droplets on a rough steel surface. Int J Heat Mass Transf 45:4561–4575

Tabbara H, Gu S (2012) Modelling of impingement phenomena for molten metallic droplets with low to high velocities. Int J Heat Mass Transf 55:2081–2208

Waldvogel JM, Poulikakos D, Wallace DB, Marusak R et al (1996) Transport phenomena in picoliter size solder droplet dispersion. J Heat Transfer 118:148–156

Wang SP, Wang GX, Matthys EF et al (1999) Deposition of a molten layer of high melting point material: substrate melting and solidification. Mater Sci Eng A 262:25–32

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer India

About this paper

Cite this paper

Shukla, R.K., Yadav, S.K., Shete, M.H., Kumar, A. (2015). Numerical Modeling of Impact and Solidification of a Molten Alloy Droplet on a Substrate. In: Narayanan, R., Dixit, U. (eds) Advances in Material Forming and Joining. Topics in Mining, Metallurgy and Materials Engineering. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2355-9_16

Download citation

DOI: https://doi.org/10.1007/978-81-322-2355-9_16

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2354-2

Online ISBN: 978-81-322-2355-9

eBook Packages: EngineeringEngineering (R0)