Abstract

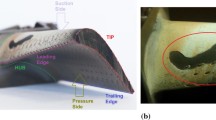

Gas turbine discs operate mostly at high temperature gradients and are subjected to mechanical loads simultaneously. The high thermal and mechanical loads eventually could result in degradation and damages in disc material, thereby increasing the risk of disc failure. In this study, a damage analysis was performed in a retired gas turbine disc made of Inconel 718. Oxidation attack and microstructural degradation as the consequence of the high service temperature have been found to be the main damages that take place in the non-contact area of the retired disc. In the blade/disc contact area, fretting fatigue occurs, with a result that cracks initiate from the oxide/metal interface and propagate in the disc alloy parallel to the sliding direction of fretting, consequently reducing the stability and safety of the disc. Meantime, oxygen diffuses into the fretting fatigue cracks, thereby exacerbating the oxidation attack. A multi-layered scale with periodic formation of the Fe-oxide/spinel layer and the metallic layer is formed on the contact surface. In both contact and non-contact area, recrystallization and α-Cr precipitation take place in the surface layer of the disc alloy. The locations where α-Cr precipitates are commonly considered to be the natural sites for mechanical weakness.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

Reference

J.M. Oblak, D.F. Paulonis, D.S. Duvall, “Coherency strengthening in Ni-base alloys hardened by DO22 gamma double prime precipitates,” Metall. Trans., 5 (1974), 143–153.

G. Greene, C. Finfrock, “Oxidation of Inconel 718 in air at high temperatures,” Oxid. Met., 55 (2001), 505–521.

R. Molins, G. Hochstetter, J. Chassaigne, E. Andrieu, “Oxidation effects on the fatigue crack growth behaviour of alloy 718 at high temperature,” Acta Mater., 45 (1997), 663–674.

P. Hancock, J. Nicholls, “Application of fracture mechanics to failure of surface oxide scales,” Mater. Sci. Techno., 4 (1988), 398–406.

L. Jian, C. Yuh, M. Farooque, “Oxidation behavior of superalloys in oxidizing and reducing environments,” Corros. Sci., 42 (2000), 1573–1585.

X. Ren, K. Sridharan, T. Allen, “Corrosion behavior of alloys 625 and 718 in supercritical water,” Corros., 63 (2007), 603–612.

P. Kofstad, High temperature corrosion (Elsevier Applied Science Publishers, Crown House, Linton Road, Barking, Essex IG 11 8 JU, UK, 1988).

Z. Chen, R. Lin Peng, P. Avdovic, J.M. Zhou, J. Moverare, F. Karlsson, S. Johansson, “Effect of thermal exposure on microstructure and nano-hardness of broached Inconel 718,” (Paper presented at Eurosuperalloys 2014, Giens, France, 12–16 May 2014).

X. Xie, G. Wang, J. Dong, C. Wu, J. Radavich, G. Shen, B.A. Lindsley, “Alpha-Cr formation in alloy 718 and its effect on creep crack propagation,” Superalloys. 718, (2001), 625–706.

S.R. Lampman, ASM Handbook: Volume 19, Fatigue and Fracture (ASM International., 1996) 321–323.

Author information

Authors and Affiliations

Rights and permissions

Copyright information

© 2014 TMS

About this paper

Cite this paper

Chen, Z., Moverare, J., Peng, R.L., Johansson, S. (2014). Damage Analysis of a Retired Gas Turbine Disc. In: Energy Materials 2014. Springer, Cham. https://doi.org/10.1007/978-3-319-48765-6_47

Download citation

DOI: https://doi.org/10.1007/978-3-319-48765-6_47

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48598-0

Online ISBN: 978-3-319-48765-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)