Abstract

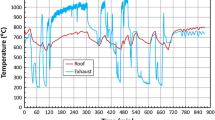

Energy makes up a major portion of the controllable costs involved in melting aluminum. While technology such as regenerative burners and multi-chamber furnaces improve energy efficiency, these technologies are expensive and difficult to cost justify given current U.S. natural gas prices. Low cost methods to improve energy efficiency without high capital outlays include process optimization, better maintenance, and furnace settings. The burners on many furnaces are over-fired and poorly controlled. This case study shows the results from a trial made with different fire rates and control schemes on a round-top aluminum melting furnace.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

B. Golchert et al., “How Flames/Loads Interaction Affects Furnace Efficiency in Round Top Furnace Operation,” Recycling and Waste Processing, ed. M. Schlesinger (TMS, 2007), pp. 61–66.

C. Belt, “Save Money by Optimizing Your Fire Rate”, Industrial Heating, April 2014

M. Roy, V. Goutiere, C. Dupuis, “Implementation of a Global Casthouse Furnace Energy Efficiency Program at Rio Tinto Alcan”, Light Metals 2010, ed. J. Johnson (TMS,2010), pp.669–673.

C. Belt, R. Peterson, and D. Bequette, “Five Low Cost Methods to Improve Energy Efficiency on Reverberatory Furnaces”, Energy Technology 2010: Conservation, Greenhouse Gas Reduction and Management, Alternative Energy Sources, ed. N. Neelameggham (TMS, 2010), pp. 71–79.

J. Wang, Y. Zhou, H. Yan, J. Zhou, “Computational Analysis of Thermal Process of a Regenerative Aluminum Melting Furnace”, Light Metals 2014, ed. J. Grandfield (TMS, 2014)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Belt, C. (2016). Case Study on Round-Top Fire Rates. In: Williams, E. (eds) Light Metals 2016. Springer, Cham. https://doi.org/10.1007/978-3-319-48251-4_126

Download citation

DOI: https://doi.org/10.1007/978-3-319-48251-4_126

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48615-4

Online ISBN: 978-3-319-48251-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)