Abstract

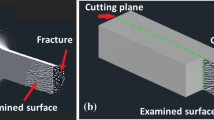

This paper describes the mechanical properties of Ti-6Al-4V alloy produced by consolidation of a blended powder mixture of elemental hydride-dehydride (HDH) titanium powder and master alloy (60Al-40V) powder. The warm pressed compacts of blended powders were sintered using a vacuum sintering furnace prior to the extrusion process. Impact toughness and micro-hardness were measured using as extruded Ti-6Al-4V alloy rod with an extrusion ratio 9:1. In addition, tensile testing was performed on extruded rod with an extrusion ratio 25:1. Detailed work was performed using optical microscopy and scanning electron microscopy to explore the microstructure and fracture surfaces of the tested material. The tensile properties of as extruded Ti-6Al-4V rod were found to be comparable with corresponding literature values of wrought material. However, impact toughness was found to be lower than published data. Some possible reasons contributing to the measured mechanical properties of the Ti-6Al-4V rods in this study are discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

A. P. Singh, B. Gabbitas and D. L. Zhang, “Fracture Toughness of Powder Metallurgy and Ingot Titanium Alloys — A Review,” Key Engineering Materials , vol. 551: Cost-Affordable Titanium IV, ed. M. A. Imam, F. H. S. Froes and R. G. Reddy (Durnten-Zurich: Trans Tech Publications, 2013), 143–160.

“Impact Properties of Titanium and Ti-6Al-4V Produced by Powder Compact Forging and Extrusion “ (Unpublished report, Waikato Centre for Advance Materials, School of Engineering, University of Waikato, Hamilton, New Zealand, 2011).

E. Yasa et al., “Experimental Investigation of Charpy Impact Tests on Metallic SLM Parts,” Innovative Developments in Design and Manufacturing: Advanced Research in Virtual and Rapid Prototyping, ed. P. J. D. Bartolo et al. (Boca Raton, FL: CRC, 2010), 207–214.

L. Wang, Z.B. Lang and H.P. Shi, “Properties and Forming Process of Prealloyed Powder Metallurgy Ti-6Al-4V Alloy,” Transactions of Nonferrous Metals Society of China, 17 (2007), S639-S643.

Titanium Alloy Guide. Retrieved 20 June, 2013, from http://rtiintl.s3.amazonaws.com/RTI-Reports/tiguide Web.pdf

ASM Aerospace Specification Metals, Titanium Ti-6Al-4V (Grade 5), Annealed. Retrieved 20 June, 2013, from http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MTP641

L.W. Meyer et al., “Dynamic Strength and Failure Behavior of Titanium Alloy Ti-6Al-4V for a Variation of Heat Treatments,” Mechanics of Time-Dependent Materials, 12 (3) (2008), 237–247.

H. Choe, S. Abkowitz and S. M. Abkowitz, “Influence of Processing on the Mechanical Properties of Ti-6A1–4V-Based Composites Reinforced with 7.5 mass% TiC and 7.5 mass% W,” Materials Transactions, 49 (9) (2008), 2153–2158.

SM Abkowitz, S. Abkowitz and H. Fisher, “Breakthrough Claimed for Titanium PM,” Metal Powder Report, 66 (6) (2011), 16–21.

Author information

Authors and Affiliations

Editor information

Rights and permissions

Copyright information

© 2014 TMS (The Minerals, Metals & Materials Society)

About this paper

Cite this paper

Singh, A.P., Gabbitas, B., Torrens, R., Yang, F., Mukhtar, A. (2014). Mechanical Properties of Ti-6Al-4V Rods Produced by Powder Compact Extrusion. In: TMS 2014: 143rd Annual Meeting & Exhibition. Springer, Cham. https://doi.org/10.1007/978-3-319-48237-8_73

Download citation

DOI: https://doi.org/10.1007/978-3-319-48237-8_73

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48593-5

Online ISBN: 978-3-319-48237-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)