Abstract

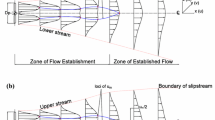

The impingement of a round jet on a flat plate at an angle θ represents a basic model of jet mechanics (Fig. 5.1). To calculate the spreading of the water sheet on the plate surface, the mass, momentum, and energy conservation laws need to be used. Under the assumptions of frictionless deflection of the jet and frictionless spreading of the water sheet, it can be deduced from the conservation law of energy that the spreading speed of the water sheet on the plate surface is equal to the jet speed. The flow distribution along a periphery circle as well as in the radial extent can then be calculated by means of the law of momentum. The mass conservation law determines that the integrated mass flow along each periphery circle should reflect the mass flow of the jet. The first accurate calculation of such a flow distribution was conducted by Hasson and Peck (1964). The distribution of the water-sheet height along the periphery of an arbitrary circle is given by

The center of the arbitrary circle coincides with the stagnation point of the round jet on the flat plate and is eccentric to the jet axis at a distance s which is given by

The interaction force between the jet at a speed C and the flat plate can be determined again by the law of momentum. Since the flow is assumed to be free of friction and hence no force component in the plane of the plate exists, the resulting interaction force is perpendicular to the flat plate. Using the momentum law in the normal direction of the flat plate, then it is calculated as

This force is referred to as . Near the stagnation point beneath the water sheet, some overpressure exists. Its integration over the plate must be equal to the jet impact force from Eq. (5.3). The pressure distribution in the immediate vicinity of the stagnation point has been determined in a study by G.I. Taylor (1960), among others.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Abgottspon, A., Stern, P., Staubli, T., Felix, D., & Winkler, K. (2013). Measuring turbine abrasion and efficiency decrease: First results of the case study at HPP Fieschertal. Hydro 2013, Innsbruck, Austria.

Boes, R. (2009). Real-time monitoring of SSC and PSD in the headwater way of a high-head hydropower plant. Proceedings of the 33rd IAHR Congress (pp. 4037–4044), Vancouver, Canada.

Boes, R., Felix, D., & Albayrak, I. (2013). Schwebstoffmonitoring zum verschleissoptimierten Betrieb von Hochdruck-Wasserkraftanlagen. Wasser Energie Luft, 105(1), 35–42.

Brekke, H., Wu, Y., & Cai, B. (2002). Design of hydraulic machinery working in sand laden water. In C. Duan & V. Karelin (Eds.), Abrasive erosion and corrosion of hydraulic machinery (Vol. 2). London: Imperial College Press.

Felix, D., Albayrak, I., Abgottspon, A., Boes, R., & Gruber, P. (2012), Suspended sediment and Pelton turbine wear monitoring: Experimental investigation of various optical and acoustic devices and beginning of the case study at HPP Fieschertal. 17th International Seminar on Hydropower Plants (pp. 483–494), Vienna, Austria.

Felix, D., Albayrak, I., Boes, R., Abgottspon, A., Deschwanden, F., & Gruber, P. (2013). Measuring suspended sediment: Results of the first year of the case study at HPP Fieschertal in the Swiss Alps. Hydro 2013, Innsbruck, Austria.

Hasson, D., & Peck, R. (1964). Thickness distribution in a sheet formed by impinging jets. American Institute of Chemical Engineers Journal, 10(5), 752–754.

Maldet, R. (2008). Pelton runner with high erosion caused by glacier sediment: assessment and measures. 15th International Seminar on Hydropower Plants (pp. 639–646), Vienna, Austria.

Raabe, J. (1989). Hydraulische Maschinen und Anlagen. VDI Verlag.

Taygun, F. (1946). Untersuchungen über den Einfluss der Schaufelzahl auf die Wirkungsweise eines Freistrahlrades. Diss., Eidgenössische Technische Hochschule in Zürich.

Taylor, G. (1960). Formation of thin flat sheets of water. Proceedings of the Royal Society Series A, 259, 1–17.

Author information

Authors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Zhang, Z. (2016). Interaction Between the Jet and Pelton Wheel. In: Pelton Turbines. Springer, Cham. https://doi.org/10.1007/978-3-319-31909-4_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-31909-4_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-31908-7

Online ISBN: 978-3-319-31909-4

eBook Packages: EngineeringEngineering (R0)