Abstract

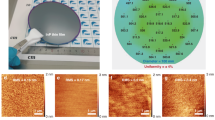

Pulsed-Laser-induced epitaxial growth (PLEG) is an attractive method for lateral overgrowth of orientation-controlled silicon (Si). As underlying MOS-FETs on the seeding crystalline Si wafer is not thermally damaged, the PLEG is promising for monolithic 3D integration of circuits. This paper will review our systematic studies of both simulation and experiment on the PLEG of Si aimed for fundamental understanding of the epitaxial growth and reduction of defect generation. Experimentally a XeCl excimer-laser irradiates the sample which consists of amorphous-silicon (a-Si) deposited on a thick SiO2 with a small contact opening on a 〈100〉 oriented SOI or bulk-Si wafer. The experiment verified our 2D transient heat transfer simulation results that the combination of the long-pulse and the bulk-Si wafer gives the widest process window. The bulk-Si wafer seeding provided the larger Si island size of 6 μm than that of the SOI (4 μm). From Electron Backscattering Diffraction (EBSD) analysis it was found that 〈100〉 is the main surface crystallographic orientation. However there exist four, isolated secondary sub-grains inside the Si island. TEM cross-sectional image revealed formation of the subgrains due to formation of Σ3 (111) type of coincident site lattice (CSL) boundary originated at the SiO2 sidewall. We believe that the gentle slope of the side wall allows the extension of the facet to the CSL boundary and subgrains. At last we introduced a way to reduce the CSL boundary formation in the PLEG of Si. By using 75∘ steep sidewalls of the opening to the seed, we have successfully obtained an array of Si islands having a size of 4 μm with {100} surface orientation only, without any subgrains inside.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

M. Koyanagi, H. Kurino, K.W. Lee, K. Sakuma, N. Miyakawa, H. Itani, Future system-on-silicon LSI chips. IEEE MICRO 18(4), 17–21 (1998)

A.W. Topol, D.C. La Tulipe Jr., L. Shi, D.J. Frank, K. Bernstein, S.E. Steen, A. Kumar, G.U. Singco, A.M. Young, K.W. Guarini, M. Ieong, Three-dimensional integrated circuits. IBM J. Res. Dev. 50(4–5), 491–506 (2006)

P. Batude, M. Vinet, A. Pouydebasque, C. Le Royer, B. Previtali, C. Tabone, J.M. Hartmann, L. Sanchez, L. Baud, V. Carron, A. Toffoli, F. Allain, V. Mazzocchi, D. Lafond, S. Deleonibus, O. Faynot, 3D monolithic integration, in 2011 IEEE International Symposium on Circuits and Systems (ISCAS) (2011), pp. 2233–2236

M.R. Tajari Mofrad, J. Derakhshandeh, R. Ishihara, A. Baiano, J. van der Cingel, C.I.M. Beenakker, Monolithic stacking of single-grain thin-film transistors. Jpn. J. Appl. Phys. (2009)

R. Ishihara, J. Derakhshandeh, M.R. Tajari Mofrad, T. Chen, N. Golshani, C.I.M. Beenakker, Monolithic 3D-ICs with single grain Si thin film transistors. Solid-State Electron. 71(0), 80–87 (2012)

J.F. Gibbons, K.F. Lee, T.J. Magee, J. Peng, R. Ormond, CW laser recrystallization of 〈100〉 Si on amorphous substrates. Appl. Phys. Lett. 34, 831 (1979)

D. Hoonhout, C.B. Kerkdijk, F.W. Saris, Silicon epitaxy by pulsed laser annealing of evaporated amorphous films. Phys. Lett. A 66(2), 145–146 (1978)

Y.-H. Son, J.-W. Lee, P. Kang, M.-G. Kang, J.B. Kim, S.H. Lee, Y.-P. Kim, I.S. Jung, B.C. Lee, S.Y. Choi, U.I. Chung, J.T. Moon, R.-I. Byung, Laser-induced epitaxial growth (LEG) technology for high density 3-D stacked memory with high productivity, in IEEE Symposium on VLSI Technology (2007), pp. 80–81

H. Ming, R. Ishihara, Y. Hiroshima, S. Indue, T. Shimoda, W. Metselaar, K. Beenakker, Effects of capping layer on grain growth with micro-Czochralski process during excimer laser crystallization. Jpn. J. Appl. Phys. Part 1 45(1A), 1–6 (2006)

R. Ishihara, W.-C. Yeh, T. Hattori, M. Matsumura, Effects of light pulse duration on excimer-laser crystallization characteristics of silicon thin films. Jpn. J. Appl. Phys. Part 1 34(4A), 1759–1764 (1995)

M. He, R. Ishihara, W. Metselaar, K. Beenakker, Agglomeration of amorphous silicon film with high energy density excimer laser irradiation. Thin Solid Films 515, 2878 (2007)

G. Caginalp, An analysis of a phase field model of a free boundary. Arch. Ration. Mech. Anal. 92, 205–245 (1986)

C.E. Krill III., L.-Q. Chen, Computer simulation of 3-d grain growth using a phase-field model. Acta Mater. 50(12), 3059–3075 (2002)

A. Burtsev, M. Apel, R. Ishihara, C.I.M. Beenakker, Phase-field modelling of excimer laser lateral crystallization of silicon thin films. Thin Solid Films 427(1–2), 309–313 (2003)

M.R. Tajari Mofrad, A. La Magnay, R. Ishihara, M. He, K. Beenakker, A three-dimensional phase-field simulation of pulsed laser induced epitaxial growth of silicon. J. Optoelectron. Adv. Mater. 12(3), 701–706 (2010)

R. Ishihara, M.R. Tajari Mofrad, M. He, C.I.M. Beenakker. To be submitted

W. Bollmann, Crystal Defects and Crystalline Interfaces (Springer, Berlin, 1970), p. 49

R. Ishihara, D. Danciu, F. Tichelaar, M. He, Y. Hiroshima, S. Inoue, T. Shimoda, J.W. Metselaar, C.I.M. Beenakker, Microstructure characterization of location-controlled Si-islands crystallized by excimer laser in the μ-Czochralski (grain filter) process. J. Cryst. Growth 299(2), 316–321 (2007)

D.T.J. Hurle, A mechanism for twin formation during Czochralski and encapsulated vertical bridgman growth of III-V compound semiconductors. J. Cryst. Growth 147, 239 (1995)

C.I. Drowley, G.A. Reid, R. Hull, Appl. Phys. Lett. 52, 546 (1988)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Ishihara, R., Tajari Mofrad, M.R., He, M., Beenakker, C.I.M. (2014). Pulsed-Laser-Induced Epitaxial Growth of Silicon for Three-Dimensional Integrated Circuits. In: Skorupa, W., Schmidt, H. (eds) Subsecond Annealing of Advanced Materials. Springer Series in Materials Science, vol 192. Springer, Cham. https://doi.org/10.1007/978-3-319-03131-6_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-03131-6_7

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-03130-9

Online ISBN: 978-3-319-03131-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)