Abstract

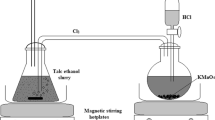

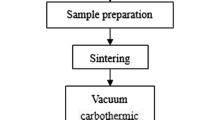

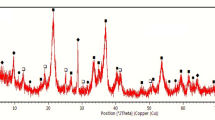

In this study, purification of rutile ore by leaching using 2–12 mol/L HCl and 2–12 wt% HF was investigated based on the thermodynamic analysis of the main involved reactions and experimental characterizations mainly using chemical titration, X-ray diffraction (XRD), and scanning electron microscopy (SEM). It was shown that compared with traditional HCl leaching, HF leaching could extract more impurities because of easier reactions between HF and impurity oxides, in spite of minor loss of TiO2 caused by its reaction with the acid. The purification performance of both acids increased initially and then decreased with increasing acid concentration. When the ore was leached using HCl with concentration of 6 mol/L at 60 °C for 4 h, the TiO2 content was enhanced from 95.39 to 97.31 wt% with the highest impurity removal percentage of 41.65%. For HF leaching, the proper acid concentration was 6 wt%. Under the same conditions as those in HCl leaching, the TiO2 content in the ore could be elevated to 98.77 wt% with the impurity removal percentage of 73.32%.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Basir A, Muhamad N, Sulong AB et al (2023) Recent advances in processing of titanium and titanium alloys through metal injection molding for biomedical applications: 2013–2022. Materials 16(11):3991

Alexander SB, Vladimirovich IO (2020) Open porous α + β titanium alloy by liquid metal dealloying for biomedical applications. Metals 10(11):1450

Mitsuo N, Yi L, Masaki N et al (2016) Biomedical titanium alloys with Young’s moduli close to that of cortical bone. Regen Biomater 3(3):173–185

Oliveira DPD, Ottria L, Gargari M et al (2017) Surface modification of titanium alloys for biomedical application: from macro to nano scale. J Biol Reg Homeos Ag 31(2):221–232

Jung EJ, Kim J, Lee YR (2021) A comparative study on the chloride effectiveness of synthetic rutile and natural rutile manufactured from ilmenite ore. Sci Rep 11(1):4050

Muhammad N, Ahmad W, Khan M et al (2021) Purification and removal of hematite from talc by acid leaching assisted by chlorination techniques. Min Metall Explor 38(5):1–9

Hiraki T, Maruyama Y, Suzuki Y et al (2018) Up-grading of natural ilmenite ore by combining oxidation and acid leaching. Int J Miner Metall Mater 25(7):729–736

Serwale MR, Coetsee T, Fazluddin S (2020) Purification of crude titanium powder produced by metallothermic reduction by acid leaching. J South Afr Inst Min Metall 120(5):349–354

Vásquez R, Molina A (2012) Effects of thermal preoxidation on reductive leaching of ilmenite. Miner Eng 39:99–105

Wu Y, Lan G (2021) Preparation technology and progress analysis in the global three major titanium dioxide process by hydrochloric acid. Titanium Ind Prog 38(1):37–44

Mostafa NY, Mahmoud MHH, Heiba ZK et al (2013) Hydrolysis of TiOCl2 leached and purified from low-grade ilmenite mineral. Hydrometallurgy 139:88–94

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Zhang, T., Peng, Z., Zuo, S. (2024). Purification of Rutile Ore by HCl and HF Leaching. In: Peng, Z., et al. Characterization of Minerals, Metals, and Materials 2024. TMS 2024. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-50304-7_20

Download citation

DOI: https://doi.org/10.1007/978-3-031-50304-7_20

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-50303-0

Online ISBN: 978-3-031-50304-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)