Abstract

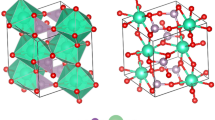

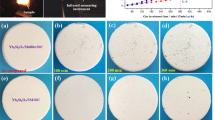

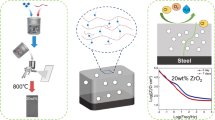

Silicon-based ceramics and composites are promising materials for hot-section structural components of high-temperature turbines due to their excellent mechanical properties at elevated temperatures. However, corrosive gas and foreign particles in the service environment, such as water vapor/oxygen and some silicate dusts may attack silicon-based ceramics, which finally result in lifetime recession and sometimes severe failure. Therefore, Environmental Barrier Coatings (EBCs) have been proposed to isolate these corrosive media. EBCs system has developed over several decades to the most common structure consisting of bond coat/interlayer/topcoat. Main performance requirements for EBCs include low-thermal conductivity, thermal expansion coefficients matched with silicon-based Ceramic Matrix Composites (CMCs), and chemical compatibility with CMCs. Meanwhile, higher fracture toughness and bonding strength with CMCs can prolong the service life of EBCs. Therefore, EBCs are usually composed of three layers: the bonding layer, interlayer, and topcoat. Nowadays, EBCs have promoted to the third generation. The topcoat of EBCs in direct contact with the environment is crucial. Rare-earth silicates are considered as the most promising materials of the EBCs topcoats, owing to their appropriate thermophysical properties and excellent chemical compatibility. Additionally, mullites or rare-earth disilicates are usually selected as the interlayer material, meanwhile the bonding layer is generally silicon. During high-temperature service, corrosive media sometimes destroy the integrity of EBCs. In order to improve the service life of EBCs, different strategies have been adopted, such as solid-solutionizing treatment and high-entropy engineering. The thermal protective system of EBCs for silicon-based ceramics and composites has been developed rapidly to the promising rare-earth silicates as topcoats for the requirements of long-term service. Based on explorations of high-temperature corrosion mechanisms under attacks of water vapor and CMAS, scientists are still struggling to perfect EBCs by different strategies in order to meet the needs of practical applications.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- APS:

-

Atmospheric plasma spraying

- BSAS:

-

Barium-strontium aluminosilicate

- CMAS:

-

Calcia-magnesia-aluminosilicate

- CMCs:

-

Ceramic matrix composites

- CTEs:

-

Coefficients of thermal expansion

- EBCs:

-

Environmental barrier coatings

- EB-PVD:

-

Electron beam physical vapor deposition

- PS-PVD:

-

Plasma spray-physical vapor deposition

- T/EBCs:

-

Thermal/environmental barrier coatings

- TBC:

-

Thermal barrier coating

- TGOs:

-

Thermal growth oxides

- YSZ:

-

Yttria-stabilized zirconia

References

Padture, N.P.: Environmental degradation of high-temperature protective coatings for ceramic-matrix composites in gas-turbine engines. NPJ Mat Degrad. (2019)

Padture, N.P.: Advanced structural ceramics in aerospace propulsion. Nat. Mater. 15(8), 804–809 (2016). https://doi.org/10.1038/nmat4687

Xu, Y., Hu, X.X., Xu, F.F., Li, K.W.: Rare earth silicate environmental barrier coatings: present status and prospective. Ceram. Int. 43(8), 5847–5855 (2017). https://doi.org/10.1016/j.ceramint.2017.01.153

Padture, N.P., Gell, M., Jordan, E.H.: Thermal barrier coatings for gas-turbine engine applications. Science 296(5566), 280–284 (2002). https://doi.org/10.1126/science.1068609

Ohnabe, H., Masaki, S., Onozuka, M., Miyahara, K., Sasa, T.: Potential application of ceramic matrix composites to aero-engine components. Compos. Part A-Appl. Sci. 30(4), 489–496 (1999). https://doi.org/10.1016/S1359-835x(98)00139-0

Parthasarathy, T.A., Cox. B., Sudre, O., Przybyla, C., Cinibulk, M.K.: Modeling environmentally induced property degradation of SiC/BN/SiC ceramic matrix composites. J. Am. Ceram. Soc. 101(3), 973–997 (2018). https://doi.org/10.1111/jace.15325

Poerschke, D.L., Jackson, R.W., Levi, C.G.: Silicate deposit degradation of engineered coatings in gas turbines: progress toward models and materials solutions. Annu. Rev. Mater. Res. 47, 297–330 (2017). https://doi.org/10.1146/annurev-matsci-010917-105000

Costa, G., Harder, B.J., Wiesner, V.L., Zhu, D.M., Bansal, N., Lee, K.N., Jacobson, N.S., Kapush, D., Ushakov, S.V., Navrotsky, A.: Thermodynamics of reaction between gas-turbine ceramic coatings and ingested CMAS corrodents. J. Am. Ceram. Soc. 102(5), 2948–2964 (2019). https://doi.org/10.1111/jace.16113

Levi, C.G., Hutchinson, J.W., Vidal-Setif, M.H., Johnson, C.A.: Environmental degradation of thermal-barrier coatings by molten deposits. Mrs Bull. 37(10), 932–941 (2012). https://doi.org/10.1557/mrs.2012.230

Gunthner, M., Schutz, A., Glatzel, U., Wang, K.S., Bordia, R.K., Greissl, O., Krenkel, W., Motz, G.: High performance environmental barrier coatings, Part I: passive filler loaded SiCN system for steel. J. Eur. Ceram. Soc. 31(15), 3003–3010 (2011). https://doi.org/10.1016/j.jeurceramsoc.2011.05.027

Liu, J., Zhang, L.T., Liu, Q.M., Cheng, L.F., Wang, Y.G.: Polymer-derived SiOC-barium-strontium aluminosilicate coatings as an environmental barrier for C/SiC composites. J. Am. Ceram. Soc. 93(12), 4148–4152 (2010). https://doi.org/10.1111/j.1551-2916.2010.04000.x

Lee, K.N.: Current status of environmental barrier coatings for Si-based ceramics. Surf Coat Tech. 133, 1–7 (2000). https://doi.org/10.1016/S0257-8972(00)00889-6

Price, J., Van-Roode, M., Stala, C.: Ceramic oxide-coated silicon carbide for high temperature corrosive environments. Key Eng. Mater. 72–74, 71–84 (1992). https://doi.org/10.4028/www.scientific.net/KEM.72-74.71

Lee, K.N., Miller, R.A.: Oxidation behavior of muilite-coated SiC and SiC/SiC composites under thermal cycling between room temperature and 1200–1400 ℃. J. Am. Ceram. Soc. 79(3), 620–626 (1996). https://doi.org/10.1111/j.1151-2916.1996.tb07920.x

Lee, K.N.: Key durability issues with mullite-based environmental barrier coatings for Si-based ceramics. J. Eng. Gas Turb. Power 122(4), 632–636 (2000). https://doi.org/10.1115/1.1287584

Fritsch, M., Klemm, H., Herrmann, M., Schenk, B.: Corrosion of selected ceramic materials in hot gas environment. J. Eur. Ceram. Soc. 26(16), 3557–3565 (2006). https://doi.org/10.1016/j.jeurceramsoc.2006.01.015

Mesquita-Guimaraes, J., Garcia, E., Miranzo, P., Osendi, M.I., Cojocaru, C.V., Lima, R.S.: Mullite-YSZ multilayered environmental barrier coatings tested in cycling conditions under water vapor atmosphere. Surf. Coat. Tech. 209, 103–109 (2012). https://doi.org/10.1016/j.surfcoat.2012.08.044

Lee, K.N., Miller, R.A.: Development and environmental durability of mullite and mullite/YSZ dual layer coatings for SiC and Si3N4 ceramics. Surf. Coat. Tech. 86(1–3), 142–148 (1996). https://doi.org/10.1016/S0257-8972(96)03074-5

Lee, K.N., Fox, D.S., Eldridge, J.I., Zhu, D.M., Robinson, R.C., Bansal, N.P., Miller, R.A.: Upper temperature limit of environmental barrier coatings based on mullite and BSAS. J. Am. Ceram. Soc. 86(8), 1299–1306 (2003). https://doi.org/10.1111/j.1151-2916.2003.tb03466.x

Liu, D., Kyaw, S.T., Flewitt, P.E.J., Seraffon, M., Simms, N.J., Pavier, M., Jones, I.A.: Residual stresses in environmental and thermal barrier coatings on curved superalloy substrates: experimental measurements and modelling. Mat. Sci. Eng. A-Struct. 606, 117–126 (2014). https://doi.org/10.1016/j.msea.2014.03.014

Cojocaru, C.V., Levesque, D., Moreau, C., Lima, R.S.: Performance of thermally sprayed Si/mullite/BSAS environmental barrier coatings exposed to thermal cycling in water vapor environment. Surf. Coat. Tech. 216, 215–223 (2013). https://doi.org/10.1016/j.surfcoat.2012.11.043

Richards, B.T., Zhao, H.B., Wadley, H.N.G.: Structure, composition, and defect control during plasma spray deposition of ytterbium silicate coatings. J. Mater. Sci. 50(24), 7939–7957 (2015). https://doi.org/10.1007/s10853-015-9358-5

Zhou, Y.C., Zhao, C., Wang, F., Sun, Y.J., Zheng, L.Y., Wang, X.H.: Theoretical prediction and experimental investigation on the thermal and mechanical properties of Bulk beta-Yb2Si2O7. J. Am. Ceram. Soc. 96(12), 3891–3900 (2013). https://doi.org/10.1111/jace.12618

Lee, K.N., Fox, D.S., Bansal, N.P.: Rare earth silicate environmental barrier coatings for SiC/SiC composites and Si3N4 ceramics. J. Eur. Ceram. Soc. 25(10), 1705–1715 (2005). https://doi.org/10.1016/j.jeurceramsoc.2004.12.013

Tian, Z.L., Lin, C.F., Zheng, L.Y., Sun, L.C., Li, J.L., Wang, J.Y.: Defect-mediated multiple-enhancement of phonon scattering and decrement of thermal conductivity in (YxYb1−x)(2)SiO5 solid solution. Acta Mater. 144, 292–304 (2018). https://doi.org/10.1016/j.actamat.2017.10.064

Boakye, E.E., Mogilevsky, P., Parthasarathy, T.A., Keller, K.A., Hay, R.S., Cinibulk, M.K.: Processing and testing of RE2Si2O7 fiber-matrix interphases for SiC-SiC composites. J. Am. Ceram. Soc. 99(2), 415–423 (2016). https://doi.org/10.1111/jace.13935

Wolf, M., Mack, D.E., Guillon, O., Vassen, R.: Resistance of pure and mixed rare earth silicates against calcium-magnesium-aluminosilicate (CMAS): a comparative study. J. Am. Ceram. Soc. 103(12), 7056–7071 (2020). https://doi.org/10.1111/jace.17328

Tejero-Martin, D., Bennett, C., Hussain, T.: A review on environmental barrier coatings: history, current state of the art and future developments. J. Eur. Ceram. Soc. 41(3), 1747–1768 (2021). https://doi.org/10.1016/j.jeurceramsoc.2020.10.057

Nguyen, S.T., Nakayama, T., Suematsu, H., Suzuki, T., He, L.F., Cho, H.B., Niihara, K.: Strength improvement and purification of Yb2Si2O7-SiC nanocomposites by surface oxidation treatment. J. Am. Ceram. Soc. 100(7), 3122–3131 (2017). https://doi.org/10.1111/jace.14831

Chen, W.R., Wu, X., Marple, B.R., Lima, R.S., Patnaik, P.C.: Pre-oxidation and TGO growth behaviour of an air-plasma-sprayed thermal barrier coating. Surf Coat Tech. 202(16), 3787–3796 (2008). https://doi.org/10.1016/j.surfcoat.2008.01.021

Peters, M., Leyens, C., Schulz, U., Kaysser, W.A.: EB-PVD thermal barrier coatings for aeroengines and gas turbines. Adv. Eng. Mater. 3(4), 193–204 (2001). https://doi.org/10.1002/1527-2648(200104)3:4%3c193::AID-ADEM193%3e3.0.CO;2-U

Wu, J., Yang, W.C., Zhang, X.F., Wang, C., Zhuo, X.S., Zhan, Y.Z., Liu, M., Zhou, K.S.: Corrosion behavior of PS-PVD spray Yb2Si2O7 environmental barrier coatings during continuous water vapor exposure. Corros Sci. 210, 110831 (2023). https://doi.org/10.1016/j.corsci.2022.110831

Lenz-Leite, M., Degenhardt, U., Krenkel, W., Schafföner, S., Motz, G.: In situ generated Yb2Si2O7 environmental barrier coatings for protection of ceramic components in the next generation of gas turbines. Adv. Mater. Interfaces 9(11) (2022). https://doi.org/10.1002/admi.202102255

Chen, X.G., Li, H.D., Zhang, H.S., Zhang, H.M., Tang, A., Su, S.: Influence of Yb substitution for La on thermophysical property of La2AlTaO7 ceramics. Ceram. Int. 43(10), 7537–7542 (2017). https://doi.org/10.1016/j.ceramint.2017.03.044

Cao, G., Wang, S.Q., Ding, Z.Y., Wang, Y.H., Liu, Z.G., Ouyang, J.H., Wang, Y.M., Wang, Y.J.: High temperature corrosion behavior and the inhibition of apatite formation evolving from corrosion of (Y1−xYbx)2SiO5 in water vapor environment. Appl. Surf. Sci. 601, 154284 (2022). https://doi.org/10.1016/j.apsusc.2022.154284

Richards, B.T., Wadley, H.N.G.: Plasma spray deposition of tri-layer environmental barrier coatings. J. Eur. Ceram. Soc. 34(12), 3069–3083 (2014). https://doi.org/10.1016/j.jeurceramsoc.2014.04.027

Chen, H., Xiang, H., Dai, F.Z., Liu, J., Zhou, Y.: High entropy (Yb0.25Y0.25Lu0.25Er0.25)2SiO5 with strong anisotropy in thermal expansion. J. Mater. Sci. Technol. 36, 134–139 (2020). https://doi.org/10.1016/j.jmst.2019.07.022

Ridley, M., Gaskins, J., Hopkins, P., Opila, E.: Tailoring thermal properties of multi-component rare earth monosilicates. Acta Mater. 195, 698–707 (2020). https://doi.org/10.1016/j.actamat.2020.06.012

Zhang, H., Lu, J., Shan, X., Wu, D., Zhao, X., Guo, F., Xiao, P.: A promising molten silicate resistant material: rare-earth oxy-apatite RE9.33(SiO4)6O2 (RE = Gd, Nd or La). J. Eur. Ceram. Soc. 40(12), 4101–4110 (2020). https://doi.org/10.1016/j.jeurceramsoc.2020.04.021

Sleeper, J., Garg, A., Wiesner, V.L., Bansal, N.P.: Thermochemical interactions between CMAS and Ca2Y8(SiO4)6O2 apatite environmental barrier coating material. J. Eur. Ceram. Soc. 39(16), 5380–5390 (2019). https://doi.org/10.1016/j.jeurceramsoc.2019.08.040

Tian, Z., Zheng, L., Wang, J., Wan, P., Li, J., Wang, J.: Theoretical and experimental determination of the major thermo-mechanical properties of RE2SiO5 (RE = Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y) for environmental and thermal barrier coating applications. J. Eur. Ceram. Soc. 36(1), 189–202 (2016). https://doi.org/10.1016/j.jeurceramsoc.2015.09.013

Turcer, L.R., Padture, N.P.: Towards multifunctional thermal environmental barrier coatings (TEBCs) based on rare-earth pyrosilicate solid-solution ceramics. Scripta Mater. 154, 111–117 (2018). https://doi.org/10.1016/j.scriptamat.2018.05.032

Tian, Z., Zheng, L., Li, Z., Li, J., Wang, J.: Exploration of the low thermal conductivities of γ-Y2Si2O7, β-Y2Si2O7, β-Yb2Si2O7, and β-Lu2Si2O7 as novel environmental barrier coating candidates. J. Eur. Ceram. Soc. 36(11), 2813–2823 (2016). https://doi.org/10.1016/j.jeurceramsoc.2016.04.022

Luo, Y., Wang, J., Li, J., Hu, Z., Wang, J.: Theoretical study on crystal structures, elastic stiffness, and intrinsic thermal conductivities of β-, γ-, and δ-Y2Si2O7. J. Mater. Res. 30(4), 493–502 (2015). https://doi.org/10.1557/jmr.2015.1

Fernandez-Carrion, A.J., Allix, M., Becerro, A.I.: Thermal expansion of rare-earth pyrosilicates. J. Am. Ceram. Soc. 96(7), 2298–2305 (2013). https://doi.org/10.1111/jace.12388

Tian, C., Liu, J., Cai, J., Zeng, Y.: Direct synthesis of La9.33Si6O26 ultrafine powder via sol–gel self-combustion method. J, Alloys Compd. 458(1–2), 378–382 (2008). https://doi.org/10.1016/j.jallcom.2007.03.128

Zhao, Z., Chen, H., Xiang, H., Dai, F.Z., Wang, X., Xu, W., Sun, K., Peng, Z., Zhou, Y.: (Y0.25Yb0.25Er0.25Lu0.25)2(Zr0.5Hf0.5)2O7: a defective fluorite structured high entropy ceramic with low thermal conductivity and close thermal expansion coefficient to Al2O3. J. Mater. Sci. Technol. 39, 167–172 (2020). https://doi.org/10.1016/j.jmst.2019.08.018

Sun, L., Luo, Y., Ren, X., Gao, Z., Du, T., Wu, Z., Wang, J.: A multicomponent γ-type (Gd1/6Tb1/6Dy1/6Tm1/6Yb1/6Lu1/6)2Si2O7 disilicate with outstanding thermal stability. Mater Res Lett. 8(11), 424–430 (2020). https://doi.org/10.1080/21663831.2020.1783007

Ren, X.M., Tian, Z.L., Zhang, J., Wang, J.Y.: Equiatomic Quaternary (Y1/4Ho1/4Er1/4Yb1/4)2SiO5 silicate: a perspective multifunctional thermal and environmental barrier coating material. Scripta Mater. 168, 47–50 (2019). https://doi.org/10.1016/j.scriptamat.2019.04.018

Wu, R., Pan, W., Ren, X., Wan, C., Qu, Z., Du, A.: An extremely low thermal conduction ceramic: RE9.33(SiO4)6O2 silicate oxyapatite. Acta Mater. 60(15), 5536–5544 (2012). https://doi.org/10.1016/j.actamat.2012.06.051

Wiesner, V.L., Vempati, U.K., Bansal, N.P.: High temperature viscosity of calcium-magnesium-aluminosilicate glass from synthetic sand. Scripta Mater. 124, 189–192 (2016). https://doi.org/10.1016/j.scriptamat.2016.07.020

Jia, R.D., Deng, L.B., Yun, F., Li, H., Zhang, X.F., Jia, X.L.: Effects of SiO2/CaO ratio on viscosity, structure, and mechanical properties of blast furnace slag glass ceramics. Mater. Chem. Phys. 233, 155–162 (2019). https://doi.org/10.1016/j.matchemphys.2019.05.065

Song, W.J., Yang, S.J., Fukumoto, M., Lavallee, Y., Lokachari, S., Guo, H.B., You, Y.C., Dingwell, D.B.: Impact interaction of in-flight high-energy molten volcanic ash droplets with jet engines. Acta Mater. 171, 119–131 (2019). https://doi.org/10.1016/j.actamat.2019.04.011

Song, W., Lavallee, Y., Wadsworth, F.B., Hess, K.U., Dingwell, D.B.: Wetting and spreading of molten volcanic ash in jet engines. J. Phys. Chem. Lett. 8(8), 1878–1884 (2017). https://doi.org/10.1021/acs.jpclett.7b00417

Li, B.T., Chen, Z., Zheng, H.Z., Li, G.F., Li, H.J., Peng, P.: Wetting mechanism of CMAS melt on YSZ surface at high temperature: first-principles calculation. Appl. Surf. Sci. 483, 811–818 (2019). https://doi.org/10.1016/j.apsusc.2019.04.009

Song, W., Lavallee, Y., Hess, K.U., Kueppers, U., Cimarelli, C., Dingwell, D.B.: Volcanic ash melting under conditions relevant to ash turbine interactions. Nat. Commun. 7, 10795 (2016). https://doi.org/10.1038/ncomms10795

Wiesner, V.L., Scales, D., Johnson, N.S., Harder, B.J., Garg, A., Bansal, N.P.: Calcium–magnesium aluminosilicate (CMAS) interactions with ytterbium silicate environmental barrier coating material at elevated temperatures. Ceram. Int. 46(10), 16733–16742 (2020). https://doi.org/10.1016/j.ceramint.2020.03.249

Sun, L., Luo, Y., Tian, Z., Du, T., Ren, X., Li, J., Hu, W., Zhang, J., Wang, J.: High temperature corrosion of (Er0.25Tm0.25Yb0.25Lu0.25)2Si2O7 environmental barrier coating material subjected to water vapor and molten calcium–magnesium–aluminosilicate (CMAS). Corros Sci. 175, 108881 (2020). https://doi.org/10.1016/j.corsci.2020.108881

Wiesner, V.L., Harder, B.J., Bansal, N.P.: High-temperature interactions of desert sand CMAS glass with yttrium disilicate environmental barrier coating material. Ceram. Int. 44(18), 22738–22743 (2018). https://doi.org/10.1016/j.ceramint.2018.09.058

Turcer, L.R., Krause, A.R., Garces, H.F., Zhang, L., Padture, N.P.: Environmental-barrier coating ceramics for resistance against attack by molten calcia-magnesia-aluminosilicate (CMAS) glass: Part I, YAlO3 and γ-Y2Si2O7. J. Eur. Ceram. Soc. 38(11), 3905–3913 (2018). https://doi.org/10.1016/j.jeurceramsoc.2018.03.021

Poerschke, D.L., Hass, D.D., Eustis, S., Seward, G.G.E.V., Sluytman, J.S., Levi, C.G., Sampath, S.: Stability and CMAS resistance of Ytterbium-Silicate/Hafnate EBCs/TBC for SiC composites. J. Am. Ceram. Soc. 98(1), 278–286 (2015). https://doi.org/10.1111/jace.13262

Grant, K.M., Krämer, S., Löfvander, J.P.A., Levi, C.G.: CMAS degradation of environmental barrier coatings. Surf. Coat. Technol. 202(4–7), 653–657 (2007). https://doi.org/10.1016/j.surfcoat.2007.06.045

Costa, G., Harder, B.J., Bansal, N.P., Kowalski, B.A., Stokes, J.L.: Thermochemistry of calcium rare-earth silicate oxyapatites. J. Am. Ceram. Soc. 103(2), 1446–1453 (2019). https://doi.org/10.1111/jace.16816

Mao, H., Selleby, M., Fabrichnaya, O.: Thermodynamic reassessment of the Y2O3-Al2O3-SiO2 system and its subsystems. Calphad 32(2), 399–412 (2008). https://doi.org/10.1016/j.calphad.2008.03.003

Godbole, E., Handt, A., Poerschke, D.: Apatite and garnet stability in the Al-Ca-Mg-Si-(Gd/Y/Yb)-O systems and implications for T/EBC: CMAS reactions. J. Am. Ceram. Soc. 105(2), 1596–1609 (2022). https://doi.org/10.1111/jace.18179

Poerschke, D.L., Shaw, J.H., Verma, N., Zok, F.W., Levi, C.G.: Interaction of yttrium disilicate environmental barrier coatings with calcium-magnesium-iron alumino-silicate melts. Acta Mater. 145, 451–461 (2018). https://doi.org/10.1016/j.actamat.2017.12.004

Turcer, L.R., Krause, A.R., Garces, H.F., Zhang, L., Padture, N.P.: Environmental-barrier coating ceramics forresistance against attack by molten calcia-magnesia-aluminosilicate (CMAS) glass: Part II, β-Yb2Si2O7 and β-Sc2Si2O7. J. Eur. Ceram. Soc. 38(11), 3914–3924 (2018). https://doi.org/10.1016/j.jeurceramsoc.2018.03.010

Ueno, S., Ohji, T., Lin, H.T.: Recession behavior of Yb2Si2O7 phase under high speed steam jet at high temperatures. Corros. Sci. 50(1), 178–182 (2008). https://doi.org/10.1016/j.corsci.2007.06.014

Richards, B.T., Begley, M.R., Wadley, H.N.G., Smialek, J.L.: Mechanisms of ytterbium monosilicate/mullite/silicon coating failure during thermal cycling in water vapor. J. Am. Ceram. Soc. 98(12), 4066–4075 (2015). https://doi.org/10.1111/jace.13792

Richards, B.T., Young, K.A., Francqueville, D.F., Sehr, S., Begley, M.R., Wadley, H.N.G.: Response of ytterbium disilicate–silicon environmental barrier coatings to thermal cycling in water vapor. Acta Mater. 106, 1–14 (2016). https://doi.org/10.1016/j.actamat.2015.12.053

Lu, Y., Luo, L., Liu, J., Zhu, C., Wang, Y., Jacobson, N.: Failure mechanism associated with the thermally grown silica scale in environmental barrier coated C/SiC composites. J. Am. Ceram. Soc. 99(8), 2713–2719 (2016). https://doi.org/10.1111/jace.14273

Lu, Y.H., Wang, Y.G.: Effects of oxygen and water vapor on the formation and growth of silica layer beneath barium strontium aluminosilicate coatings. Ceram. Int. 44(7), 8570–8575 (2018). https://doi.org/10.1016/j.ceramint.2018.02.062

Lu, Y., Cao, Y., Zhao, X.: Optimal rare-earth disilicates as top coat in multilayer environmental barrier coatings. J. Alloys Compd. 769, 1026–1033 (2018). https://doi.org/10.1016/j.jallcom.2018.08.084

Courcot, E., Rebillat, F., Teyssandier, F., Louchet-Pouillerie, C.: Stability of rare earth oxides in a moist environment at elevated temperatures-experimental and thermodynamic studies. J. Eur. Ceram. Soc. 30(9), 1911–1917 (2010). https://doi.org/10.1016/j.jeurceramsoc.2010.02.012

Maier, N., Nickel, K.G., Rixecker, G.: High temperature water vapour corrosion of rare earth disilicates (Y, Yb, Lu)2Si2O7 in the presence of Al(OH)3 impurities. J. Eur. Ceram. Soc. 27(7), 2705–2713 (2007). https://doi.org/10.1016/j.jeurceramsoc.2006.09.013

Parker, C.G., Opila, E.J.: Stability of the Y2O3-SiO2 system in high-temperature, high-velocity water vapor. J. Am. Ceram. Soc. 103(4), 2715–2726 (2019). https://doi.org/10.1111/jace.16915

Ridley, M., Opila, E.: Thermochemical stability and microstructural evolution of Yb2Si2O7 in high-velocity high-temperature water vapor. J. Eur. Ceram. Soc. 41(5), 3141–3149 (2021). https://doi.org/10.1016/j.jeurceramsoc.2020.05.071

Al-Nasiri, N., Patra, N., Jayaseelan, D.D., Lee, W.E.: Water vapour corrosion of rare earth monosilicates for environmental barrier coating application. Ceram. Int. 43(10), 7393–7400 (2017). https://doi.org/10.1016/j.ceramint.2017.02.123

García, E., Miranzo, P., Osendi, M.I.: The prospect of Y2SiO5-based materials as protective layer in environmental barrier coatings. J. Therm. Spray Technol. 22(5), 680–689 (2013). https://doi.org/10.1007/s11666-013-9917-8

Wang, Y.W., Niu, Y.R., Zhong, X., Shi, M.H., Mao, F.Q., Zhang, L., Li, Q.L., Zheng, X.B.: Water vapor corrosion behaviors of plasma sprayed ytterbium silicate coatings. Ceram. Int. 46(18), 28237–28243 (2020). https://doi.org/10.1016/j.ceramint.2020.07.324

Wang, Y., Liu, J.: Corrosion of barium aluminosilicates by water-vapour: an investigation from first principles. Corros. Sci. 51(9), 2126–2129 (2009). https://doi.org/10.1016/j.corsci.2009.05.040

Wang, Y.W., Niu, Y.R., Zhong, X., Shi, M.H., Mao, F.Q., Zhang, L., Li, Q.L., Zheng, X.B.: Water vapor corrosion behaviors of plasma sprayed RE2SiO5 (RE = Gd, Y, Er) coatings. Corros Sci. 167, 108529 (2020). https://doi.org/10.1016/j.corsci.2020.108529

Tian, Z.L., Zhang, J., Sun, L.C., Zheng, L.Y., Wang, J.Y.: Robust hydrophobicity and evaporation inertness of rare-earth monosilicates in hot steam at very high temperature. J. Am. Ceram. Soc. 102(6), 3076–3080 (2019). https://doi.org/10.1111/jace.16315

Jacobson, N.S., Butt, D.: Silica activity measurements in the Y2O3-SiO2 system and applications to modeling of coating volatility. J. Am. Ceram. Soc. 97(6), 1959–1965 (2014). https://doi.org/10.1111/jace.12974

Costa, G.C.C., Jacobson, N.S.: Mass spectrometric measurements of the silica activity in the Yb2O3–SiO2 system and implications to assess the degradation of silicate-based coatings in combustion environments. J. Eur. Ceram. Soc. 35(15), 4259–4267 (2015). https://doi.org/10.1016/j.jeurceramsoc.2015.07.019

Kowalski, B.A., Jacobson, N.S., Bodenschatz, C., Costa, G.: Thermodynamics of the Lu2O3-SiO2 system and comparison to other rare earth silicates. J. Chem. Thermodyn. 161, 106483 (2021). https://doi.org/10.1016/j.jct.2021.106483

Ridley, M.J., Opila, E.J.: High-temperature water-vapor reaction mechanism of barium strontium aluminosilicate (BSAS). J. Eur. Ceram. Soc. 42(7), 3305–3312 (2022). https://doi.org/10.1016/j.jeurceramsoc.2022.02.004

Zhao, G., Xu, B., Ren, K., Shao, G., Wang, Y.: Oxygen diffusion through environmental barrier coating materials. Ceram. Int. 46(11), 19545–19549 (2020). https://doi.org/10.1016/j.ceramint.2020.05.007

Dong, Y., Ren, K., Lu, Y., Wang, Q., Liu, J., Wang, Y.: High-entropy environmental barrier coating for the ceramic matrix composites. J. Eur. Ceram. Soc. 39(7), 2574–2579 (2019). https://doi.org/10.1016/j.jeurceramsoc.2019.02.022

Tian, Z.L., Zheng, L.Y., Hu, W.P., Sun, L.C., Zhang, J., Wang, J.Y.: Tunable properties of (HoxY1−x)2SiO5 as damage self-monitoring environmental/thermal barrier coating candidates. Sci. Rep-UK 9, 415 (2019). https://doi.org/10.1038/s41598-018-36883-2

Cao, G., Ouyang, J.H., Li, Y., Liu, Z.G., Ding, Z.Y., Wang, Y.H., Jin, Y.J., Wang, Y.M., Wang, Y.J.: Improved thermophysical properties of rare-earth monosilicates applied as environmental barrier coatings by adjusting structural distortion with RE-doping. J. Eur. Ceram. Soc. 41(14), 7222–7232 (2021). https://doi.org/10.1016/j.jeurceramsoc.2021.07.029

Guo, X., Zhang, Y., Li, T., Zhang, P., Shuai, K., Li, J., Shi, X.: High-entropy rare-earth disilicate (Lu0.2Yb0.2Er0.2Tm0.2Sc0.2)2Si2O7: a potential environmental barrier coating material. J. Eur. Ceram. Soc. 42(8):3570–3578 (2022). https://doi.org/10.1016/j.jeurceramsoc.2022.03.006

Chen, Z., Tian, Z., Zheng, L., Ming, K., Ren, X., Wang, J., Li, B.: (Ho0.25Lu0.25Yb0.25Eu0.25)2SiO5 high-entropy ceramic with low thermal conductivity, tunable thermal expansion coefficient, and excellent resistance to CMAS corrosion. J. Adv. Ceram. 11(8), 1279–1293 (2022). https://doi.org/10.1007/s40145-022-0609-z

Wang, X., He, Y., Wang, C., Bai, Y., Zhang, F., Wu, Y., Song, G., Wang, Z.J.: Thermal performance regulation of high-entropy rare-earth disilicate for thermal environmental barrier coating materials. J. Am. Ceram. Soc. 105(7), 4588–4594 (2022). https://doi.org/10.1111/jace.18456

Luo, Y., Sun, L., Wang, J., Du, T., Zhou, C., Zhang, J., Wang, J.: Phase formation capability and compositional design of beta-phase multiple rare-earth principal component disilicates. Nat. Commun. 14(1), 1275 (2023). https://doi.org/10.1038/s41467-023-36947-6

Turcer, L.R., Padture, N.P.: Rare-earth pyrosilicate solid-solution environmental-barrier coating ceramics for resistance against attack by molten calcia–magnesia–aluminosilicate (CMAS) glass. J. Mater. Res. 35(17), 2373–2384 (2020). https://doi.org/10.1557/jmr.2020.132

Zhang, X., Zhou, K., Liu, M., Deng, C., Deng, C., Niu, S., Xu, S., Su, Y.: CMAS corrosion and thermal cycle of Al-modified PS-PVD environmental barrier coating. Ceram. Int. 44(13), 15959–15964 (2018). https://doi.org/10.1016/j.ceramint.2018.06.019

Wolf, M., Mack, D.E., Guillon, O., Vaßen, R.: Resistance of pure and mixed rare earth silicates against calcium-magnesium-aluminosilicate (CMAS): a comparative study. J. Am. Ceram. Soc. 103(12), 7056–7071 (2020). https://doi.org/10.1111/jace.17328

Harder, B.J.: Oxidation performance of Si-HfO2 environmental barrier coating bond coats deposited via plasma spray-physical vapor deposition. Surf. Coat. Technol. 384 (2020). https://doi.org/10.1016/j.surfcoat.2019.125311

Nguyen, S.T., Nakayama, T., Suematsu, H., Iwasawa, H., Suzuki, T., Otsuka, Y., He, L., Takahashi, T., Niihara, K.: Self-healing behavior and strength recovery of ytterbium disilicate ceramic reinforced with silicon carbide nanofillers. J. Eur. Ceram. Soc. 39(10), 3139–3152 (2019). https://doi.org/10.1016/j.jeurceramsoc.2019.03.040

Chen, Y., Lu, Y., Ye, Q., Wang, Y.: A self-healing environmental barrier coating: TiSi2-doped Y2Si2O7/barium strontium aluminosilicate coating. Surf. Coat. Technol. 307, 436–440 (2016). https://doi.org/10.1016/j.surfcoat.2016.09.020

Zhang, X., Song, J., Deng, Z., Wang, C., Niu, S., Liu, G., Deng, C., Deng, C., Liu, M., Zhou, K., Lu, J.: Interface evolution of Si/Mullite/Yb2SiO5 PS-PVD environmental barrier coatings under high temperature. J. Eur. Ceram. Soc. 40(4), 1478–1487 (2020). https://doi.org/10.1016/j.jeurceramsoc.2019.10.062

Jang, B.K., Nagashima, N., Kim, S., Oh, Y.S., Lee, S.M., Kim, H.T.: Mechanical properties and microstructure of Yb2SiO5 environmental barrier coatings under isothermal heat treatment. J. Eur. Ceram. Soc. 40(7), 2667–2673 (2020). https://doi.org/10.1016/j.jeurceramsoc.2019.12.057

Summers, W.D., Begley, M.R., Zok, F.W.: Transition from penetration cracking to spallation in environmental barrier coatings on ceramic composites. Surf. Coat. Technol. 378(25), 125083 (2019). https://doi.org/10.1016/j.surfcoat.2019.125083

Zhai, Z., Wang, W., Mei, X., Li, M., Cui, J., Wang, F., Pan, A.: Effect of the surface microstructure ablated by femtosecond laser on the bonding strength of EBCs for SiC/SiC composites. Opt. Commun. 424, 137–144 (2018). https://doi.org/10.1016/j.optcom.2018.04.055

Zhong, X., Niu, Y., Li, H., Zeng, Y., Zheng, X., Ding, C., Sun, J.: Microstructure evolution and thermomechanical properties of plasma-sprayed Yb2SiO5 coating during thermal aging. J. Am. Ceram. Soc. 100(5), 1896–1906 (2017). https://doi.org/10.1111/jace.14690

Appleby, M.P., Zhu, D., Morscher, G.N.: Mechanical properties and real-time damage evaluations of environmental barrier coated SiC/SiC CMCs subjected to tensile loading under thermal gradients. Surf. Coat. Technol. 284, 318–326 (2015). https://doi.org/10.1016/j.surfcoat.2015.07.042

Hong, Z., Cheng, L., Zhang, L., Wang, Y.: Internal friction behavior of C/SiC composites with environmental barrier coatings in corrosive environment. Int. J. Appl. Ceram. Technol. 8(2), 342–350 (2011). https://doi.org/10.1111/j.1744-7402.2010.02589.x

Xu, Y., Yan, Z.: Investigation on the preparation of Si/Mullite/Yb2Si2O7 environmental barrier coatings onto silicon carbide. J. Rare Earths 28(3), 399–402 (2010). https://doi.org/10.1016/s1002-0721(09)60120-4

Zhong, X., Niu, Y., Li, H., Zhu, T., Song, X., Zeng, Y., Zheng, X., Ding, C., Sun, J.: Comparative study on high-temperature performance and thermal shock behavior of plasma-sprayed Yb2SiO5 and Yb2Si2O7 coatings. Surf. Coat. Technol. 349, 636–646 (2018). https://doi.org/10.1016/j.surfcoat.2018.06.056

Zhong, X., Niu, Y., Li, H., Zhou, H., Dong, S., Zheng, X., Ding, C., Sun, J.: Thermal shock resistance of tri-layer Yb2SiO5/Yb2Si2O7/Si coating for SiC and SiC-matrix composites. J. Am. Ceram. Soc. 101(10), 4743–4752 (2018). https://doi.org/10.1111/jace.15713

Summers, W.D., Poerschke, D.L., Begley, M.R., Levi, C.G., Zok, F.W.: A computational modeling framework for reaction and failure of environmental barrier coatings under silicate deposits. J. Am. Ceram. Soc. 103, 5196–5213 (2020). https://doi.org/10.1111/jace.17187

Stolzenburg, F., Kenesei, P., Almer, J., Lee, K.N., Johnson, M.T., Faber, K.T.: The influence of calcium–magnesium–aluminosilicate deposits on internal stresses in Yb2Si2O7 multilayer environmental barrier coatings. Acta Mater. 105, 189–198 (2016). https://doi.org/10.1016/j.actamat.2015.12.016

Acknowledgements

The financial support from the National Science and Technology Major Project (2017-VI-0020-0093) and the Heilongjiang Postdoctoral Science Foundation are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Ouyang, JH., Cao, G., Wang, SQ. (2024). Environmental Barrier Coatings (EBCs) for Silicon-Based Ceramics and Composites. In: Pakseresht, A., Amirtharaj Mosas, K.K. (eds) Ceramic Coatings for High-Temperature Environments. Engineering Materials. Springer, Cham. https://doi.org/10.1007/978-3-031-40809-0_8

Download citation

DOI: https://doi.org/10.1007/978-3-031-40809-0_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-40808-3

Online ISBN: 978-3-031-40809-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)