Abstract

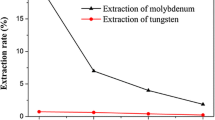

Separation of tungsten (W) and vanadium (V) is of great significance for the utilization of the polymetallic complex minerals and secondary resources of these elements. In this work, selective extraction of V from sodium tungstate solution was investigated using 2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester (P507) as an extractant. The extraction process was studied to optimize various parameters including initial pH, extractant concentration, phase ratio (O/A), temperature, and contact time. The simulation calculation indicated W and V exist in the form of cation HW7O245− and anion VO2+, respectively, in solutions with pH ranging from 1 to 3, which provided a theoretical basis for the selective separation of W and V. In addition, under the optimum conditions (pH = 1.5, 20% (v/v) P507, O/A = 1/2, room temperature, and T = 20 min), the removal efficiency of V exceeds 90% with W loss below 6%.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Zhang Y, Zhang TA, Dreisinger D, Zhou W, Xie F, Lv G, Zhang W (2018) Chelating extraction of vanadium(V) from low pH sulfuric acid solution by Mextral 973H. Sep Purif Technol 190:123–135

Zhang WJ, Li JT, Zhao ZW, Huang SB, Chen XY, Hu KL (2015) Recovery and separation of W and Mo from high-molybdenum synthetic scheelite in HCl solutions containing H2O2. Hydrometallurgy 155:1–5

Zhang WJ, Chen YQ, Che JY, Wang CY, Ma BZ (2020) Green leaching of tungsten from synthetic scheelite with sulfuric acid-hydrogen peroxide solution to prepare tungstic acid. Sep Purif Technol 241:116752

Luo DS, Huang J, Zhang YM, Liu H, Hu PC (2020) Efficient and environment-friendly vanadium (V) extraction from vanadium shale leachate using tri-n-octylmethylammonium chloride. Sep Purif Technol 237:116482

Nguyen TH, Lee MS (2014) Separation of vanadium and tungsten from sodium molybdate solution by solvent extraction. Ind Eng Chem Res 53(20):8608–8614

Zhang JL, Zhao ZW (2014) Thermodynamic analysis of tungsten-vanadium separation in W(VI)-V(V)-H2O system. Chin J Nonferr Met 24(6):1656–1662

Nguyen TH, Lee MS (2016) A review on the separation of molybdenum, tungsten, and vanadium from leach liquors of diverse resources by solvent extraction. Geosyst Eng 19(5):247–259

Choi IH, Moon G, Lee JY, Jyothi RK (2018) Hydrometallurgical processing of spent selective catalytic reduction (SCR) catalyst for recovery of tungsten. Hydrometallurgy 178:137–145

Luo L, Kejun L, Shibayama A, Yen W, Fujita T, Shindo O, Katai T (2004) Recovery of tungsten and vanadium from tungsten alloy scrap. Hydrometallurgy 72(1–2):1–8

Wang HY, Han GH, Huang YF, Su SP (2022) Solvent extraction separation of tungsten and vanadium from simulated leaching solution of spent SCR catalyst. In: Ouchi T, Azimi G, Forsberg K, Kim H, Alam S, Neelameggham N, Baba A, Peng H (eds) Rare metal technology 2022. Springer, Berlin, pp 93–100

Liu LJ, Wang LL, Su S, Yang T, Dai ZJ, Qing MX, Xu K, Hu S, Wang Y, Xiang J (2019) Leaching behavior of vanadium from spent SCR catalyst and its immobilization in cement-based solidification/stabilization with sulfurizing agent. Fuel 243:406–412

Han GH, Wang HY, Su SP, Huang YF, Liu BB (2021) Research progress and discussion on selective separation technology of dissolved tungsten and vanadium. Chin J Nonferr Met 31(11):3380–3395

Ferella F (2020) A review on management and recycling of spent selective catalytic reduction catalysts. J Clean Prod 246:118990

Zhang QJ, Wu YF, Yuan HR (2020) Recycling strategies of spent V2O5-WO3/TiO2 catalyst: a review. Resour Conserv Recycl 161:104983

Rout PC, Mishra GK, Padh B, Suresh KR, Ramachandra Reddy B (2017) Solvent extraction separation of molybdenum as thio-molybdate complex from alkaline tungsten leach liquor of spent HDS catalyst—a pilot study. Hydrometallurgy 174:140–146

Wang LP, Zhang GQ, Guan WJ, Zeng L, Zhou Q, Xia Y, Wang Q, Li QG, Cao ZY (2018) Complete removal of trace vanadium from ammonium tungstate solutions by solvent extraction. Hydrometallurgy 179:268–273

Truong HT, Nguyen TH, Lee MS (2017) Separation of molybdenum(VI), rhenium(VII), tungsten(VI), and vanadium(V) by solvent extraction. Hydrometallurgy 171:298–305

Zhang J, Zhu ZW, Chen DS, Wang LN, Wang WJ, Lei Z (2019) Preparation of highly pure vanadium electrolyte by solvent extraction and purification using P507 from V(IV) solution. Chin J Rare Met 43(3):303–311

Su SP, Huang YF, Liu BB, Han GH, Xue YB, Wang YZ (2021) A feasible strategy for deeply separating low concentrations of molybdenum from tungstate solutions with a high-efficiency microbubble floating-extraction concept. ACS Sustain Chem Eng 10(1):146–158

Xiong P, Zhang YM, Huang J, Bao SX, Yang X, Shen C (2017) High-efficient and selective extraction of vanadium (V) with N235–P507 synergistic extraction system. Chem Eng Res Des 120:284–290

Acknowledgements

This work was financially supported by the Original Exploration Project of China (52150079), the Natural Science Foundation of China (U2004215, No. 51974280, and No. 51774252), and the Educational Commission Fund of Henan Province of China (No. 20HASTIT012, No. 18A450001, and No. 17A450001).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Wang, H., Han, G., Huang, Y., Su, S., Liu, B., Shi, K. (2023). Selective Extraction of Vanadium from Sodium Tungstate Solution Using P507. In: Reddy, R.G., et al. New Directions in Mineral Processing, Extractive Metallurgy, Recycling and Waste Minimization. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22765-3_39

Download citation

DOI: https://doi.org/10.1007/978-3-031-22765-3_39

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22764-6

Online ISBN: 978-3-031-22765-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)