Abstract

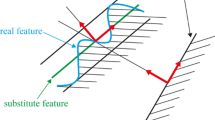

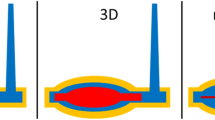

Large parts produced by injection moulding are usually subjected to large deformations that may be reduced during assembly. The single parts manufacturing specification should refer to the as produced (free) state. On the other hand, the functional specification, derived from the assembly functional specification should address the “as assembled” state. Geometrical inspection, based on the functional specification requires dedicated fixtures to simulate the “as assembled” state. This contribution suggests a procedure, based on FEM simulation, to correlate the geometric specification at the “as assembled” state with the “as produced” (free) state, applied to an industrial case study. The result of the procedure are free state tolerance limits, e.g., manufacturing specification, that allows conformity of the part to the functional specification once assembled. The part may be inspected based on the manufacturing specification fixtureless during mass production. The result of the case study shows a significant reduction in position and orientation error due to the assembly process as it was expected.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

ISO International Organization for Standardization. ISO 10579:2013 - Geometrical Product Specifications (GPS). Dimensioning and Tolerancing. Non-Rigid Parts, Geneva (2013).

ISO International Organization for Standardization. ISO/TS 21619:2018 - Geometrical Product Specifications (GPS) - Types of Documents with GPS, Geneva (2018)

Anselmetti, B., Louati, H.: Generation of Manufacturing Tolerancing with ISO Standards. Int. J. Mach. Tools Manuf. 45 (2005). https://doi.org/10.1016/j.ijmachtools.2005.01.001

Sellem, E., Rivière, A.: Tolerance analysis of deformable assemblies. In: Volume 2: 24th Design Automation Conference. American Society of Mechanical Engineers (1998). https://doi.org/10.1115/DETC98/DAC-5571

Charles Liu, S., Jack Hu, S.: An offset finite element model and its applications in predicting sheet metal assembly variation. Int. J. Mach. Tools Manuf. 35, 1545–1557 (1995). https://doi.org/10.1016/0890-6955(94)00103-Q

Liu, S.C., Hu, S.J., Woo, T.C.: Tolerance analysis for sheet metal assemblies. J. Mech. Des. 118, 62–67 (1996). https://doi.org/10.1115/1.2826857

Liu, S.C., Hu, S.J.: Variation simulation for deformable sheet metal assemblies using finite element methods. J. Manuf. Sci. Eng. 119, 368–374 (1997). https://doi.org/10.1115/1.2831115

Atik, H., Chahbouni, M., Amegouz, D., Boutahari, S.: Optimization tolerancing of surface in flexible parts and assembly: influence coefficient method with shape defects. Int. J. Eng. Technol. 7, 90 (2018). https://doi.org/10.14419/ijet.v7i1.8470

Atik, H., Chahbouni, M., Amagouz, D., Boutahari, S.: An analysis of springback of compliant assemblies by contact modeling and welding distortion. Int. J. Eng. Technol. 7, 85 (2018). https://doi.org/10.14419/ijet.v7i1.8330

Polini, W., Corrado, A.: Methods of influence coefficients to evaluate stress and deviation distribution of flexible assemblies—a review. Int. J. Adv. Manuf. Technol. 107(5–6), 2901–2915 (2020). https://doi.org/10.1007/s00170-020-05210-3

Stockinger, A., Lustig, R., Meerkamm, H.: Computer-based and experimental validation of an approach to combine tolerance zones with elastic deformations. In: Proceedings of the 16th International Conference on Engineering Design (ICED 2007). DS 42 (2007)

Radvar-Esfahlan, H., Tahan, S.-A.: Nonrigid geometric metrology using generalized numerical inspection fixtures. Precis. Eng. 36, 1–9 (2012). https://doi.org/10.1016/j.precisioneng.2011.07.002

Sabri, V., Tahan, S.A., Pham, X.T., Moreau, D., Galibois, S.: Fixtureless profile inspection of non-rigid parts using the numerical inspection fixture with improved definition of displacement boundary conditions. Int. J. Adv. Manuf. Technol. 82(5–8), 1343–1352 (2015). https://doi.org/10.1007/s00170-015-7425-3

Sabri, V., Sattarpanah, S., Tahan, S.A., Cuillière, J.C., François, V., Pham, X.T.: A robust and automated FE-based method for fixtureless dimensional metrology of non-rigid parts using an improved numerical inspection fixture. Int. J. Adv. Manuf. Technol. 92(5–8), 2411–2423 (2017). https://doi.org/10.1007/s00170-017-0216-2

Raynaud, S., Wolff, V., Dinh, T.T., Pareja, O.: Modélisation et évaluation de l’incertitude de mesure lors de l’utilisation de MMT avec des pièces déformables. In: Larquier, B. (ed.) 17th International Congress of Metrology. p. 13006. EDP Sciences, Les Ulis (2015). https://doi.org/10.1051/metrology/201513006

ISO International Organization for Standardization. ISO 1101:2017 - Geometrical Product Specifications (GPS). Geometrical Tolerancing. Tolerances of Form, Orientation, Location and Run-out, Geneva (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Maltauro, M., Meneghello, R., Concheri, G., Pellegrini, D., Viero, M., Bisognin, G. (2023). A Case Study on the Correlation Between Functional and Manufacturing Specifications for a Large Injection Moulded Part. In: Gerbino, S., Lanzotti, A., Martorelli, M., Mirálbes Buil, R., Rizzi, C., Roucoules, L. (eds) Advances on Mechanics, Design Engineering and Manufacturing IV. JCM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-15928-2_111

Download citation

DOI: https://doi.org/10.1007/978-3-031-15928-2_111

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-15927-5

Online ISBN: 978-3-031-15928-2

eBook Packages: EngineeringEngineering (R0)