Abstract

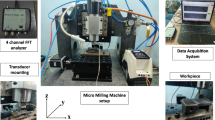

Surface finish is influenced by two major combined factors: tool wear and cutting parameters. In order to conduct optimization trials by varying cutting parameters, it is important to evaluate the influence of tool wear on the surface finish. An experimental approach is designed to conduct a series of milling operations and to monitor the vibration levels in three directions to detect the tool wear vibratory impact on resulting surface finish. A low vibration level recorded thanks to a specific accelerometers’ setup would suggest that the obtained surface finishes depend only on the cutting conditions and would allow to suppress the influence of the tool wear if it turns out to be negligible. This method will enable to analyze the surface characteristics, after the elimination of the tool wear factor, by focusing only on a set of cutting conditions as input. Vibration signals measured while machining Supra50 parts showed insignificant amplitudes, proving that the surface finish only depends on cutting conditions and confirming that both of the influencing factors are decoupled. Vibratory signals were compared for three different solid carbide end mills using RMS indicator on three stages of the protocol. The vibratory fluctuations can be neglected reinforcing the dissociation hypothesis.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Tayal, A., Kalsi, N.S., Gupta, M.K.: Machining of superalloys: a review on machining parameters, cutting tools, and cooling methods. Proc. Mater. Today 43(4), 1839–1849 (2020)

Coromant, S.: Heat resistant super alloys – HRSA, pp. 9–42 (2010)

Xu, K., Zou, B., Huang, C., Yao, Y., Zhou, H., Liu, Z.: Machinability of Hastelloy C-276 using hot-pressed sintered Ti based cermet cutting tools. Chin. J. Mech. Eng. 28(3), 599–606 (2015)

Sai Krishnan, G., Ganesh Babu, L., Kumaran, P., Yoganjaneyulu, G., Sudhan Raj, J.: Investigation of Caryota urens fibers on physical, chemical, mechanical and tribological properties for brake pad applications. Mater. Res. Express 7(1), 015310 (2019)

Choudhury, S.K., Srinivas, P.: Tool wear prediction in turning. J. Mater. Process. Technol. 153–154, 276–280 (2004)

Horng, J.T., Tsong, J., Liu, N., Chiang, K.: Investigating the machinability evaluation of hadfield steel in the hard turning with AL2O3/TiC mixed ceramic tool based on the response surface methodology. J. Mater. Process. Technol. 208, 532–541 (2008)

Mansour, A., Abdalla, H.: Surface roughness prediction based on cutting parameters and tool vibrations in turning operations. J. Mater. Process. Technol. 124, 183–191 (2002)

Zhou, J.M., Andersson, M., Stähl, J.E.: A system for monitoring cutting tool spontaneous failure based on stress estimation. J. Mater. Process. Technol. 48, 231 (1995)

Balasubramanian, V., Lakshminarayanan, A.K.: Comparison of RSM with ANN in predicting tensile strength of friction stir welded AA7039 aluminium alloy joints. Trans. Nonferr. Metals Soc. China 19, 9–18 (2009)

Sharif, S., Azlan Mohd, Z., Habibollah, H.: Prediction of surface roughness in the end milling machining using artificial neural network. Expert Syst. Appl. 37, 1755–1768 (2010)

Sahasrabudhe, A.D., Risbood, K.A., Dixit, U.S.: Prediction of surface roughness and dimensional deviation by measuring cutting forces and vibrations in turning process. J. Mater. Process. Technol. 132, 203–214 (2003)

Goupy, J.: Pratiquer les plan d’expériences. Dunod, Paris (2005)

Tomassone, R., Audrain, S., Lesquoy, E., Miller, C.: La Régression, Nouveaux Regards sur une Ancienne Méthode Statistique. INRA et MASSON, Paris (1992)

Jobson, J.D.: Applied Multivariate Data Analysis. Regression and Experimental Design, vol. 1. Springer, New York (1999). https://doi.org/10.1007/978-1-4612-0955-3

Chankong, V., Haimes, Y.Y.: Multiobjective Decision Making Theory and Methodology. North-Holland, New York (1983)

Miettinen, K.: Nonlinear Multiobjective Optimization. Kluwer, Boston (1999)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Frih, A.S., Ftoutou, E., Ben Khalifa, A., Hajjaji, I., Trigui, M. (2023). Experimental Study of the Vibration Level Resulting from Supra50 Milling. In: Walha, L., et al. Design and Modeling of Mechanical Systems - V. CMSM 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-14615-2_19

Download citation

DOI: https://doi.org/10.1007/978-3-031-14615-2_19

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-14614-5

Online ISBN: 978-3-031-14615-2

eBook Packages: EngineeringEngineering (R0)