Abstract

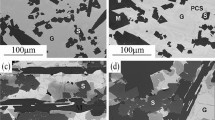

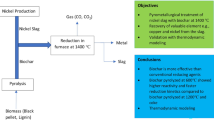

Smelting reduction of lead-rich slag is a clean technology recently developed in China to produce primary lead metal. The technology has the advantages of more efficient capture of SO2 and lead fugitive emissions and low energy consumption. The extent of the slag reduction was continuously measured by the product gas volume. Effect of PbO concentration on the reduction of lead-rich slag was determined in the temperature range 1073–1473 K. The reduction of lead-rich slag by carbon was found to be chemically controlled at early stage and then diffusion-controlled at late stage. The activation energy for chemically controlled reduction decreases with increasing PbO concentration in lead-rich slag. The reaction mechanism has been discussed by experimental results and FactSage 8.1.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Chen HY, Li AJ, Finlow DE (2009) The lead and lead-acid battery industries during 2002 and 2007 in China. J Power Sources 191(1):22–27

Zhu XF, Lei L, Sun XJ, Yang DN, Gao LX, Liu JW, Kumar RV, Yang JK (2012) Preparation of basic lead oxide from spent lead acid battery paste via chemical conversion. Hydrometallurgy 117–118:24–31

Wu XS (2020) Application of CSC technology in nonferrous metallurgy. Paper presented at the 9th international symposium on lead and zinc processing, United States, San Diego, 23–27 Feb 2020

Li WF, Zhan J, Fan YQ, Wei C, Zhang CF, Hang JY (2017) Research and industrial application of a process for direct reduction of molten high-lead smelting slag. JOM 69(4):784–789

Matyas AG, Mackey PJ (1976) Metallurgy of the direct smelting of lead. JOM 28(11):10–15

Hou XM, Chou KC, Zhao B (2013) Reduction kinetics of lead-rich slag with carbon in the temperature range of 1073 to 1473 K. J Min Metall B 49(2):201–206

Errington B, Arthur P, Wang J, Dong Y (2005) The ISA-YMG lead smelting process. Paper presented at proceedings of the international symposium on lead and zinc processing, Japan, Kyoto, 17–19 Oct 2005

Kinaev NN, Jak E, Hayes PC (2010) Kinetics of reduction of lead smelting slags with solid carbon. Scand J Metall 34(2):150–157

Zhao B, Errington B, Jak E, Peter H (2010) Gaseous reduction of synthetic lead slags and industrial lead sinters. Can Metall Quart 49(3):241–248

Liao JF, Zhao B (2021) Phase equilibria study in the system “Fe2O3”–ZnO–Al2O3–(PbO+CaO+SiO2) in air. Calphad 74:102282

Wang JK, Zhao B, Yang G, Peter H (2004) Properties and reduction mechanism of lead-rich slags. Nonferrous Metals 6:5–8

Yang G, Zhao B, Wang JK, Peter H (2006) Study on reduction behaviors between lead-rich slag and sinter. Nonferrous Metals 4:10–13

Yang G, Zhao B, Wang JK, Peter H (2008) Study of different behaviors between lead-rich slags and sinter during reduction. Nonferrous Metals 4:5–7

Dickinson CF, Heal GR (1999) Solid–liquid diffusion controlled rate equations. Thermochim Acta 340:89–103

Bidari E, Aghazadeh V (2015) Investigation of copper ammonia leaching from smelter slags: characterization, leaching and kinetics. Metall Mater Trans B 46:2305–2314

Vegliò F, Trifoni M, Pagnanelli F, Toro L (2001) Shrinking core model with variable activation energy: a kinetic model of manganiferous ore leaching with sulphuric acid and lactose. Hydrometallurgy 60(2):167–179

Pritzker MD (2003) Model for parallel surface and pore diffusion of an adsorbate in a spherical adsorbent particle. Chem Eng Sci 58(2):473–478

Bale CW, Bélisle E, Chartrand P, Degterov SA, Eriksson G, Gheribi AE, Hack K, Jung IH, Kang YB, Melançon J, Pelton AD, Petersen S, Robelin C, Sangster J, Spencer P, Van Ende MA (2016) FactSage thermochemical software and databases. Calphad 54:35–53

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Xie, S., Liao, C., Zhao, B. (2022). Experimental Studies on Reduction Mechanisms of Lead-Rich Slag with Different PbO Concentrations. In: Peng, Z., et al. 12th International Symposium on High-Temperature Metallurgical Processing. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-92388-4_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-92388-4_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-92387-7

Online ISBN: 978-3-030-92388-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)