Abstract

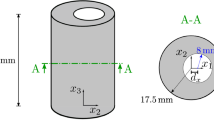

In production engineering, current research focuses on the induction of targeted residual stress states in components in order to improve their properties rather than follow the usual path of minimizing residual stresses to prevent failure. In this contribution, a focus is laid on the investigation of the subsequent cooling process of hot bulk formed parts. Such cooling of a component leads to a microscopic phase transformation, which has to be considered in order to compute residual stresses inside the material. A numerical approach based on a phenomenological macroscopic material model is presented to depict the related stress evolution.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Macherauch E, Wohlfahrt H, Wolfstied U (1973) Härterei-Technische Mittelungen - Zeitschrift für Werkstoffe. Wärmebehandlung, Fertigung. 28:201–211

Kloos KH (1979) Eigenspannungen. Definition und Entstehungsursachen. Zeitschrift für Werkstofftechnik. 10:293–302

Withers PJ, Bhadeshia HKDH (2001) Residual stress Part 1 - Measurement techniques. Mater Sci Technol 17:355–365

Withers PJ, Bhadeshia HKDH (2001) Residual stress Part 2 - Nature and origins. Mater Sci Technol 17:366–375

Greenwood GW, Johnson RH (1965) The Deformation of Metals Under Small Stresses During Phase Transformations. Proceedings of the Royal Society of London A 183:403–422

Leblond JB (1989) Mathematical Modelling of Transformation Plasticity in Steels II: Coupling with Strain Hardening Phenomena. Int J Plast 5:573–591

Weisz-Patrault D (2017) Multiphase model for transformation induced plasticity. Extended Leblond’s model. J Mech Phys Solids 106:152–175

Mahnken R, Schneidt A, Antretter T (2009) Macro modelling and homogenization for transformation induced plasticity of a low-alloy steel. Int J Plast 25:183–204

Hallberg H, Håkansson P, Ristinmaa M (2010) Thermo-mechanically coupled model of diffusionless phase transformation in austenitic steel. Int J Solids Struct 47:1580–1591

Inoue T (2011) Mechanics and Characteristics of Transformation Plasticity and Metallo-thermo-mechanical Process Simulation. Procedia Eng 10:3793–3798

Zaera R, Rodríguez-Martínez JA, Casado A, Fernández-Sáez J, Rusinek A, Pesci R (2012) A constitutive model for analyzing martensite formation in austenitic steels deforming at high strain rates. Int J Plast 29:77–101

Ostwald R, Bartel T, Menzel A (2015) An energy-barrier-based computational micro-sphere model for phase-transformations interacting with plasticity. Comp Methods Appl Mech Eng 293:232–265

Tahimi A, Barbe F, Taleb L, Quey R, Guillet A (2012) Evaluation of microstructure-based transformation plasticity models from experiments on 100C6 steel. Comput Mater Sci 52:55–60

Ni J, Wang X, Gong J, Wahab MA (2018) A multi-phase model for transformation plasticity using thermodynamics-based metallurgical algorithm. Int J Mech Sci 148:135–148

Zhang D, Liang Y, Du Z, Mao X (2013) A Material Model for Steel Plates during the Cooling Process. Adv Technol Solut Ind 710:329–333

Connolly DS, Kohar CP, Mishra RK, Inal K (2018) A new coupled thermomechanical framework for modeling formability in transformation induced plasticity steels. Int J Plast 103:39–66

Seupel A, Burgold A, Prüger S, Budnitzki M, Kuna M (2020) Modeling of the thermomechanical behavior, damage, and fracture of high alloy TRIP-steel. In: Biermann H, Aneziris CG (eds) Austenitic TRIP/TWIP steels and steel-zirconia composites: design of tough, transformation-strengthened composites and structures. 723–769

Prüger S, Kiefer B (2020) Towards the crystal plasticity based modeling of TRIP-steels - from material point to structural simulations. In Biermann H, Aneziris CG (eds) Austenitic TRIP/TWIP steels and steel-zirconia composites: design of tough, transformation-strengthened composites and structures. 793–823

Prüger S, Gandhi A, Balzani D (2016) Modeling of low-alloyed TRIP-steels based on direct micro-macro simulations. ECCOMAS Congress 2016:2280–2291

Soliman M, Palkowski H (2008) On factors affecting the phase transformation and mechanical properties of cold-rolled transformation-induced-plasticity-aided steel. Metall Mater Trans A 39:2513

Behrens B-A, Bouguecha A, Bonk C, Chugreev A (2017) Experimental investigations on the transformation-induced plasticity in a high tensile steel under varying thermo-mechanical loading. Comput Methods Mat Sci 17:36–43

Liu J, Li M, Zhang P, Zhu Y, Li S (2020) Experiment research on the transformation plasticity by tensile/compressive stress and transformation kinetics during the martensitic transformation of 30Cr2Ni4MoV steel. Mater Res Express 6:1265g8

Uebing S, Brands D, Scheunemann L, Schröder J (2021) Residual stresses in hot bulk formed parts - two-scale approach for austenite-to-martensite phase transformation. Archive Appl Mech. https://doi.org/10.1007/s00419-020-01836-7

Uebing S, Brands D, Scheunemann L, Schröder J (2021) Residual stresses in hot bulk formed parts - Microscopic stress analysis for austenite-to-martensite phase transformation. Archive Appl Mech. https://doi.org/10.1007/s00419-021-01921-5

Behrens B-A, Chugreev A, Kock C (2019) Macroscopic FE-simulation of residual stresses in thermo-mechanically processed steels considering phase transformation effects. XV. Int Conf Comput Plast. Fundam Appl 211–222

Behrens B-A, Schröder J, Brands D, Scheunemann L, Niekamp R, Chugreev A, Sarhil M, Uebing S, Kock C (2019) Experimental and numerical investigations on the development of residual stresses in thermo-mechanically processed Cr-alloyed steel 1.3505. Metals 9:28

Koistinen DP, Marburger RE (1959) A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon and plain carbon steels. Acta Metall 7:59–60

Lemaitre J (2001) Handbook of materials behavior models. Academic Press

Wolff M, Boettcher S, Böhm M (2007) Phase transformations in steels in the multi-phase case-general modelling and parameter identification. Universität Bremen, Zentum für Technomathematik

Simo JC, Hughes TJR (1998) Computational Inelasticity. Springer

Wolfram Research, Inc.: Mathematica, Version 12.0. Champaign, IL (2019)

Taylor RL (2020) FEAP - Finite element analysis program. http://projects.ce.berkeley.edu/feap

Schenk O, Gärtner K (2004) Solving unsymmetric sparse systems of linear equations with PARDISO. Future Gener Comput Syst 20:475–487

Acknowledgments

This project is funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation)—374871564 (BE 1691/223-2, BR 5278/3-2, SCHR 570/33-2) within the priority program SPP 2013. The authors gratefully acknowledge the computing time granted by the Center for Computational Sciences and Simulations (CCSS) of the University of Duisburg-Essen and provided on the supercomputer magnitUDE (DFG grants INST 20876/209-1 FUGG, INST 20876/243-1 FUGG) at the Zentrum für Informations- und Mediendienste (ZIM).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Uebing, S. et al. (2021). Residual Stresses in Hot Bulk Formed Parts—A Phenomenological Approach for the Austenite-to-Martensite Phase Transformation. In: Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y. (eds) Forming the Future. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-75381-8_196

Download citation

DOI: https://doi.org/10.1007/978-3-030-75381-8_196

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75380-1

Online ISBN: 978-3-030-75381-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)