Abstract

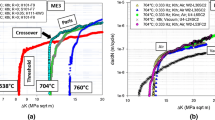

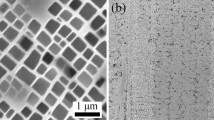

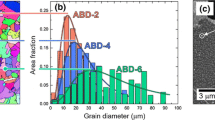

Effect of creep deformation at crack tip on fatigue crack propagation behavior in a single crystal and a directionally solidified superalloys at 900 °C was investigated. Creep-fatigue crack propagation tests with single tension hold introduced into cyclic fatigue loading were conducted. In specimen extracted from the single-crystal superalloy, ICMSX-4, when the cyclic fatigue loading was restarted after the tension hold, nascent crack was immediately initiated followed by significant crack retardation. This crack propagation behavior was ascribed to mechanisms based on two different concepts of residual compressive stress and crack closure. From the viewpoint of mechanism based on the residual stress concept, material degradation at crack tip induced by the tension hold was investigated using scanning electron microscope, while stress relaxation and the resultant residual compressive stress at crack tip were quantified by elastic-plastic-creep finite element analysis coupled with digital image correlation technique. Finally, crack propagation behavior in polycrystalline specimen extracted from the directionally solidified superalloy, MGA1400, was investigated focusing on effect of grain boundary. An insight into criteria of a transition from crack retardation to accelerated intergranular cracking was suggested based on a relative grain size to “creep affected zone.”

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Shahinian P, Sadananda K (1984) Creep and Fatigue Crack Growth in Several Cast Superalloys. Paper Presented at the 5th International Symposium on Superalloys, Champion, Pennsylvania, 7–11 October 1984

Okazaki M, Yamazaki Y (1999) Creep-fatigue small crack propagation in a single crystal Ni-base superalloy, CMSX-2, Microstructural influences and environmental effects. Int. J. Fat. 21(1):S79–S86. https://doi.org/10.1016/s0142-1123(99)00058-4

Palmert F, Moverare J, Gustafsson D, Busse C (2018) Fatigue crack growth behaviour of an alternative single crystal nickel base superalloy. Int. J. Fat. 109:166–181. https://doi.org/10.1016/j.ijfatigue.2017.12.003

Sadananda K, Shahinian P (1978) Hold-time effects on high temperature fatigue crack growth in Udimet 700. J. Mater. Sci. 13(11):2347–2357. https://doi.org/10.1007/bf00808048

Liu X, Kang B, Chang KM (2003) The effect of hold-time on fatigue crack growth behaviors of WASPALOY alloy at elevated temperature. Mater. Sci. Eng. A 340(1–2):8–14. https://doi.org/10.1016/s0921-5093(02)00074-6

Taira S, Ohtani R, Komatsu T (1979) Application of J-Integral to High-Temperature Crack Propagation: Part II—Fatigue Crack Propagation. J. Eng. Mater. Technol. 101(2):162–167. https://doi.org/10.1115/1.3443669

Suzuki S, Sakaguchi M (2020) Fatigue crack retardation associated with creep deformation induce d by a tension hold in a single crystal Ni-base superalloy. Scr. Mater. 178: 346–350. https://doi.org/10.1016/j.scriptamat.2019.11.058

ASTM International (2008) Standard Test Method for Measurement of Fatigue Crack Growth Rates. Annual Book of ASTM Standards E647-08, ASTM International, West Conshohocken, Pennsylvania, pp 669–713

Suzuki S, Sakaguchi M, Inoue H (2018) Temperature dependent fatigue crack propagation in a single crystal Ni-base superalloy affected by primary and secondary orientations. Mater. Sci. Eng. A 724(2):559–565. https://doi.org/10.1016/j.msea.2018.03.090

Sakaguchi M, Komamura R, Chen X, Higaki M, Inoue H (2019) Crystal plasticity assessment of crystallographic Stage I crack propagation in a Ni-based single crystal superalloy. Int. J. Fat. 123:10–21. https://doi.org/10.1016/j.ijfatigue.2019.02.003

Chen X, Sakaguchi M (2020) Transition behavior from Mode I cracking to crystallographic cracking in a Ni-base single crystal superalloy. Int. J. Fat. 132:105400. https://doi.org/10.1016/j.ijfatigue.2019.105400

Ott M, Mughrabi H (1999) Dependence of the high-temperature low-cycle fatigue behaviour of the monocrystalline nickel-base superalloys CMSX-4 and CMSX-6 on the γ/γ′-morphology. Mater. Sci. Eng. A 272(1): 24–30. https://doi.org/10.1016/s0921-5093(99)00453-0

Kagawa H, Mukai Y (2012) The Effect of Crystal Orientation and Temperature on Fatigue Crack Growth of Ni-based Single Crystal Superalloy. Paper Presented at the 12th International Symposium on Superalloys, Champion, Pennsylvania, 9–13 September 2012

Reed RC, Matan N, Cox DC, Rist MA, Rae CMF (1999) Creep of CMSX-4 Superalloy Single Crystals: Effects of Rafting at High Temperature. Acta Mater. 47(12):3367–3381. https://doi.org/10.1016/s1359-6454(99)00217-7

Svoboda J, Lukáš P (2000) Creep deformation modelling of superalloy single crystals. Acta Mater. 48(10):2519–2528. https://doi.org/10.1016/s1359-6454(00)00078-1

Kakehi K, Takahashi S (2005) Influence of Aging Heat Treatment on Creep Strength of CMSX4. J. Soc. Mater. Sci., Jpn. 54(2):136–142. https://doi.org/10.2472/jsms.54.136

MacLachlan DW, Wright LW, Gunturi S, Knowles DM (2001) Constitutive modelling of anisotropic creep deformation in single crystal blade alloys SRR99 and CMSX-4. Int. J. Plast. 17(4):441–467. https://doi.org/10.1016/s0749-6419(00)00058-9

Epishin A, Fedelich B, Nolze G, Schriever S, Feldmann T, Ijaz MF, Viguier B, Poquillon D, Bouar YL, Ruffini A, Finel A (2018) Creep of Single Crystals of Nickel-Based Superalloys at Ultra-High Homologous Temperature. Metall. Mater. Trans. A 49(9):3973–3987. https://doi.org/10.1007/s11661-018-4729-6

Blaber J, Adair B, Antoniou A (2015) Ncorr: open-source 2D digital image correlation matlab software. Exp. Mech. 55:1105–1122. https://doi.org/10.1007/s11340-015-0009-1

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Suzuki, S. et al. (2020). Competing Mechanism of Creep Damage and Stress Relaxation in Creep-Fatigue Crack Propagation in Ni-Base Superalloys. In: Tin, S., et al. Superalloys 2020. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-51834-9_34

Download citation

DOI: https://doi.org/10.1007/978-3-030-51834-9_34

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-51833-2

Online ISBN: 978-3-030-51834-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)