Abstract

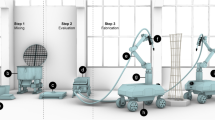

The research investigates architectural-scale concrete 3D printing in robotically fabricated recyclable molds for the fabrication of rapidly constructed, structurally optimized, architectural-scale concrete structures. The research of Print-Cast Concrete utilizes a three-dimensional extrusion path for deposition of material over a subtractive shaped sub-structure of CNC tooled compacted green sand. This process expedites the production of doubly curved concrete geometries by replacing traditional formwork casting or horizontal corbeling with spatial concrete arching deposited in relation to optimized structural loads. Creating robust non-zero Gaussian curvature in concrete, this method increases speed over typical pre-cast concrete fabrication practices, especially when producing mass customized unique elements. Through the casting component of this method, concrete 3D prints have greater resolution along the edge condition resulting in tighter assembly tolerances between multiple aggregated components. Addressing digital form finding and optimization, material behaviors, and novel utilization of robotic fabrication, this research work displays a series of key concepts within Print-Cast Concrete, advancing edge condition precision of extrusion-based 3DCP.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Carpo, M.: The Alphabet and the Algorithm. MIT Press, Cambridge (2011)

Yee, A.: Structural and economic benefits of precast/prestressed concrete construction. PCI J. 46(4), 34–42 (2001)

Ballard, G., Harper, N., Zabelle, T.: Learning to see work flow: an application of lean concepts to precast concrete construction. Eng. Constr. Archit. Manag. 10(1), 6–14 (2003)

Khoshnevis, B.: Automated construction by contour crafting-related robotics and information technologies. Autom. Cronstr. 13(1), 5–19 (2004)

Bos, F., Wolfs, R., Ahmed, Z., Salet, T.: Additive manufacturing of concrete in construction: potentials and challenges of 3D concrete printing. Virtual Phys. Prototyping 11(3), 209–225 (2016)

Gosselin, C., Romain Duballet, P., Roux, N.G., Dirrenberger, J., Morel, P.: Large-scale 3D printing of ultra-high performance concrete-a new processing route for architects and builders. Mater. Des. 100, 102–109 (2016)

Hwang, D., Khoshnevis, B.: Concrete wall fabrication by contour crafting. In: 21st International Symposium on Automation and Robotics on Construction (ISARC 2004), Jeju, South Korea (2004)

Lim, S., Buswell, R.A., Le, T.T., Austin, S.A., Gibb, A.G.F., Thorpe, T.: Developments in construction-scale additive manufacturing process. Autom. Const. 21, 262–268 (2012)

Battaglia, C., Miller, M., Zivkovic, S.: Sub-additive 3D printing of optimized double curved concrete lattice structures. In: Willmann, J., Block, P., Hutter, M., Byrne, K., Schork, T. (eds.) Robotic Fabrication in Architecture, Art and Design 2018, vol. 1, pp. 245–255. Springer, Heidelberg (2019)

Zivkovic, S., Battaglia, C.: Rough pass extrusion tooling, CNC post processing of 3D-printed sub-additive concrete lattice structures. In: Anzalone, P., Signore, M., Wit, A. (eds.) ACADIA Recalibration on Imprecision and Infidelity 2018, pp. 302–311 (2018)

Zephir, A.: Le Corbusier: Phillips Pavilion, Brussels, 1958. A Treasury of World’s Fair Art and Architecture (2005). Accessed 1 July 2018

Banchhor, R., Ganguly, K.: Optimization in green sand casting process for efficient, economic, economical and quality casting. Int. J. Adv. Eng. Technol. V(1), 25–29 (2014)

Gramzio Kohler Research. https://gramaziokohler.arch.ethz.ch/web/e/lehre/211.html. Accessed 2 Oct 2020

Verian, K.P., Kowaleski, S.R., Carli, M.D., Bright, R.P., Maandi, E., Still, G.: The properties of 3D printing mortar and development of 3D construction printing. Transp. Res. Rec. 2674(2) (2020)

ASTM C1437-15, Standard Test Method for Flow of Hydraulic Cement Mortar, ASTM International, West Conshohocken, PA (2015). www.astm.org

ASTM C266-18, Standard Test Method for Time of Setting of Hydraulic-Cement Paste by Gillmore Needles, ASTM International, West Conshohocken, PA (2018). www.astm.org

ASTM C109/C109M-16a, Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens), ASTM International, West Conshohocken, PA (2016). www.astm.org

ASTM C307-18, Standard Test Method for Tensile Strength of Chemical-Resistant Mortar, Grouts, and Monolithic Surfacings, ASTM International, West Conshohocken, PA (2018). www.astm.org

Ko, M., Shin, D., Ahn, H., Park, H.: InFormed ceramics: multi-axis clay 3D printing on freeform molds. In: Willmann, J., Block, P., Hutter, M., Byrne, K., Schork, T. (eds.) Robotic Fabrication in Architecture, Art and Design 2018, vol. 1, pp. 297–308. Springer, Heidelberg (2019)

Mostafavi, S., Kemper, B., Fischer, D.: Multimode robotic materialization: design to robotic fabrication method of integrating subtractively produced hard components and additively deposited soft silicone. In: Willmann, J., Block, P., Hutter, M., Byrne, K., Schork, T. (eds.) Robotic Fabrication in Architecture, Art and Design 2018, pp. 349–362. Springer, Cham (2019)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 RILEM

About this paper

Cite this paper

Battaglia, C.A., Miller, M.F., Verian, K.P. (2020). Print-Cast Concrete: Additive Manufacturing for 3D Printing Mortar in Robotically Fabricated Green Sand Molds. In: Bos, F., Lucas, S., Wolfs, R., Salet, T. (eds) Second RILEM International Conference on Concrete and Digital Fabrication. DC 2020. RILEM Bookseries, vol 28. Springer, Cham. https://doi.org/10.1007/978-3-030-49916-7_75

Download citation

DOI: https://doi.org/10.1007/978-3-030-49916-7_75

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-49915-0

Online ISBN: 978-3-030-49916-7

eBook Packages: EngineeringEngineering (R0)